Food Packaging Film-What are the uses and benefits of them

With the continuous development of the packaging industry, while packaging brings convenience and benefits to people, its waste also causes serious harm to the environment where human beings live. Therefore, food packaging film has become an important product for food storage and packaging. It can prolong the shelf life of products, protect the appearance and quality of food, and make it generate certain economic benefits. Therefore, the use of food film is particularly important.

Table of Content:

The role of food packaging film

Features of food packaging film

Production Process of Food packaging film

The craftsmanship of Food packaging film

Application of food packaging film

Why use food packaging film?

The demand for food packaging film shows a continuous upward trend, mainly because food packaging film can be used in different food packaging and processing work, and has a very good protective effect on food, so in most cases, people will choose to use food packaging film as a protective film for preservation and storage.

The role of food packaging film

To a certain extent, food packaging film can shield small molecular gases, liquids, water vapor, aroma, etc., so it can play a role in the preservation of food quality, freshness, and flavor and prolong shelf life. It is not only widely used in the food packaging industry, but also plays a very important role in pharmaceutical packaging.

Food packaging film plays a protective role on food, protects the freshness of food, and prevents dust, bacteria, etc. It greatly facilitates the circulation of food.

1. Protect food and extend the shelf life of food:

Protect the appearance quality of food, promote food competition, increase food sales, and generate certain economic benefits.

Protect the original quality of food and prolong the shelf life of food

2 Packaged food is convenient for circulation

During the whole circulation process of food, it has to be handled, loaded and unloaded, transported, and stored, which is easy to cause damage to the appearance and quality of food. If it is directly irradiated by sunlight and light, and at a high temperature, it is easy to cause food to oxidize, change color, and taste bad. and other phenomena, such as the use of corresponding vacuum packaging, inflatable packaging, etc. after inner and outer packaging, the food can be well protected to avoid damage.

The food itself has certain nutrients and moisture, which are the basic conditions for the production and reproduction of bacteria, mildew, yeast, etc. When the temperature of food storage is suitable for their reproduction, it will cause food spoilage. If the food is aseptically packaged or subjected to high-temperature sterilization, refrigeration, and other treatments after packaging, it will prevent the occurrence of food spoilage and prolong the shelf life of the food.

3. Packaged food is convenient for circulation

Some packages are containers for food circulation. Such as bottled wine, beverages, canned food, field-packed milk powder, etc. These packaged bottles, cans, and bags are not only packaging containers, but also transfer tools for food circulation and sales. It brings great convenience to food circulation.

4. Increase the variety of convenience foods

Fresh food that is convenient for consumers, such as quick-frozen dumplings, packaged meals, fruits, aquatic products, etc., can be convenient for people to eat.

5. Prevent food contamination:

For example, when cooking food is in circulation, it must be in contact with containers and human hands, which is easy to contaminate the food. Packaged food can avoid this phenomenon, which is beneficial to the health of consumers.

The advantages of food packaging film:

Food packaging film is one of the basic varieties of BOPP heat-sealing film. It is a polypropylene heat-sealing film made of biaxially stretched using heat-sealing masterbatch on the surface layer. It has lightweight, non-toxic, odorless, moisture-proof, and mechanical strength. High, good dimensional stability, excellent transparency, excellent printing performance after surface treatment, and so on.

The food packaging film has high transparency, the product is environmentally friendly and non-toxic, and meets the international standards for environmentally friendly packaging and cling film. During heat sealing, no toxic gas will be produced; it has the right and flawless molding ability for various special-shaped products; the heat sealing film has high transparency and good gloss, which can display the appearance of the product and increase the desire to buy; tough and tear-resistant, Good flexibility, not easy to be embrittled, durable and high tear strength, to ensure that the packaged goods will not be deformed after being stored for a long time.

Features of food packaging film:

The flatness of the film surface is good, which is suitable for high-speed packaging;

Good transparency, high stiffness, low static electricity;

The heat sealing temperature is low, the haze is low, and the sliding property is good;

The film has good heat sealing performance and processing adaptability.

Production Process of Food packaging film:

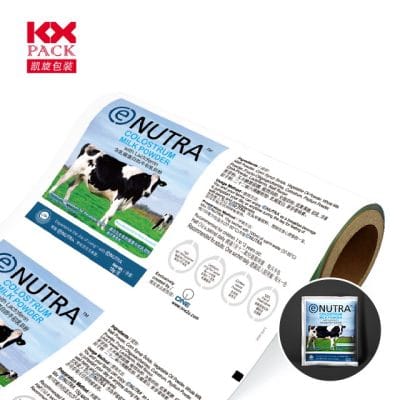

- Packaging design: Design the layout of the packaging bag according to customer requirements, and then give it to the manufacturer.

- Copper plate making: It is to make the copper plate required on the printing machine according to the confirmation draft of the packaging bag design. The specific plate size should be determined according to the product packaging design in the previous step.

- Layout printing: Install the prepared copper plate on the packaging printing machine, and then print it according to the information confirmed by the customer.

- Composite material: The so-called composite material is to bond the two materials together, and stick the ink surface between the two layers of materials, such as nylon (nylon)/PE (reinforcing material).

- Bag-making and bag-cutting: bag-making and bag-cutting are done on one machine. When the material is compounded, it is placed on the bag-making machine. After debugging the bag-making machine, it can be carried out according to the adjusted size. Heat-sealed packaging bag materials, and finally cut the bag food packaging according to the adjusted size.

The craftsmanship of Food packaging film:

Food packaging films are generally produced by two processes: blow molding and casting.

One is the blow molding process.

Water cooling is cooled by direct contact with the film surface, so it can be cooled quickly, spherical stretching, its flatness is slightly lower than that of the casting method, but the transparency is better than the Liuyan Process, and spherical stretching has a high barrier to the produced food The ductility of the stretched film has a certain influence.

The second is Liuyan process.

The high-barrier food packaging film is cooled by cold rolls, and the obtained high-barrier food packaging film has a certain stretch in the longitudinal direction and no stretch in the transverse direction. The integrity is good, and the transparency is lower than that of the blow molding method.

Types of food packaging films

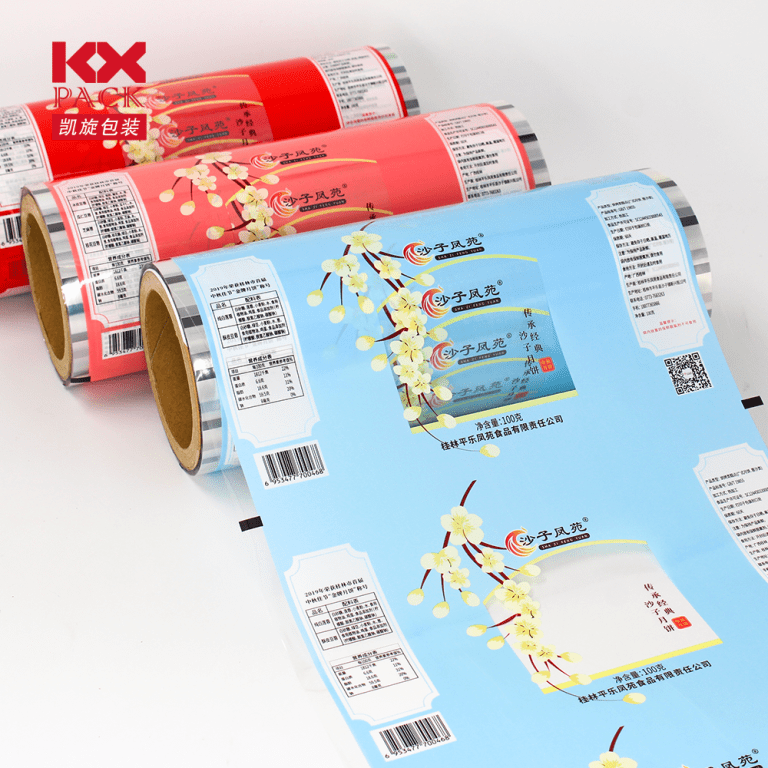

The types of food packaging films include meat product packaging, brewing powder packaging, agricultural and sideline food packaging, seasoning packaging, leisure packaging, roasted nuts, dried fruit packaging, and another food packaging.

Application of food packaging film:

Food categories: biscuits, potato chips, snow cakes, cakes, chewing gum, chocolate, hawthorn slices, schema, etc.;

Daily necessities: cosmetics, mosquito coil boxes, playing card boxes, condoms, paper rolls, etc.;

All kinds of paper towels, spoons, chopsticks, straws, masks, dishes packaging

Packaging of textiles, audio-visual products, CD-ROMs, hardware accessories, etc.

Precautions for the use of food packaging film:

Careful loading and unloading, protect the roll body and surface, avoid direct sunlight and rain, and store in a cool, dry place.

For more detailed types or questions about food packaging films, please refer to: https://kxpack.com/product-category/plastic-film/

We provide but are not limited to high-quality products, competitive prices, excellent service, etc.