Custom food packaging bags

We have extensive experience in custom food-grade packaging bags and can provide high-quality solutions for your export business.

You can choose materials, sizes, thickness, designs etc. for bags that suit your target market and food products. We can also customize the printing of your brand logo, product information, etc. based on your visual branding. Our products are food-grade tested to ensure safety.

Moreover, we have the capability for large-scale production of custom bags to ensure stable supply. If you have any customization needs, please let us know and our designers and technicians will do their best to provide branding packaging bags for your export business.

Showcasing Products

How to Contorol Quality and Safety of Food Packaging Bags?

Ensuring superior Quality and Safety is at the heart of our Custom Food Packaging Bags’ production process. Here’s how we maintain our high standards:

Material Selection: We utilize high-quality, food-grade materials in our products, which are devoid of any harmful toxins or odors. Our materials are thoroughly tested and vetted for their safety and ability to retain food quality over time.

Moisture and Heat Resistant: Our Custom Food Packaging Bags are designed to resist moisture and heat to prevent any damage that may compromise the integrity of packaged food.

Sealing and Protection: The bags are engineered with superior sealing technology that protects the food from any external contaminants, insects, or bacteria.

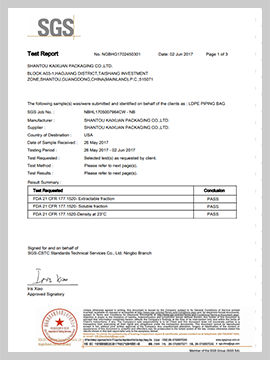

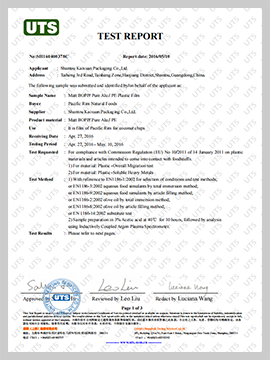

Compliance with Standards: Our bags adhere strictly to international food safety protocols, such as FDA, EU 10/2011, and other applicable guidelines. We ensure our products are consistently reliable through regular and rigorous quality inspections.

Product Transparency: Integral information such as the material used, production date, expiry date, and any specific handling instructions are clearly labeled on each bag. This provides consumers the assurance of the packaged food’s safety and quality.

Benefits of Custom Food Packaging Bags

Custom Food Packaging Bags offer a wealth of benefits to businesses and consumers alike. From efficient protection to significant branding opportunities, here are some key advantages:

- Food Preservation: These bags are designed to keep food fresh and free from contaminants, thereby ensuring the longevity of the product.

- Custom Design and Branding: Customization allows businesses to align their packaging with brand aesthetics while standing out on the shelf.

- Convenience: With the option of resealable closures, handles, and other specific requirements, personalized food packaging bags provide convenience to end-users.

- Sustainability: Modern food packaging materials can be environmentally friendly — recyclable or compostable — supporting eco-conscious business practices.

Why Choose Kaixuan

Shantou Kaixuan Packaging Co., Ltd.

Direct manufactory focus on packaging for over 20 years, especially in color printing, blister and bag making.

Integrated in design, production and sales

Kaixuan factory covers an area of 200000m², equipped with a 100000 level dust-free workshop, 300m/min 12 color high-speed gravure printing machine, automatic high-speed blister machine with German technology , eight side sealing bag making machine and other high-standard bag making equipment.

No Benzene No Ketone Ink

Meanwhile, we are using benzene free and ketone free ink and other eco-friendly materials. Your daily capacity could reach 150 tons, absolutely meet your needs in Safe, efficient and healthy.

18,000 m

200+

100+

$10,000,000

Certificates

Who is Our Partners

Food Packaging Bags FAQ

Q1: What materials are used in your food packaging bags?

A1: Our custom food packaging bags are made from top-grade food safe plastic, ensuring no toxicity or contaminants. They effectively protect food from moisture and oxygen, keeping your products fresh.

Q2: Can the food packaging bags be tailored to meet specific size or shape requirements?

A2: Absolutely! We offer a full customization service. Whether you require unique size specifications or a particular shape for your food packaging bag, we’ve got you covered.

Q3: How long does it take for the production and delivery of bulk orders?

A3: Typically, for bulk orders exceeding 1000 units, we require 15-20 working days for production. Transit times vary based on destination and chosen shipment method.

Q4: How can I submit my design for the food packaging bags?

A4: You can submit your design directly through our website or send it to us by email. We will create a sample for your confirmation, ensuring the final product is produced exactly to your design specifications.

WHAT THEY SAID

Information on Food Packaging Bags

Top 10 food packaging bag Manufacturers and Suppliers in China

Discover the ‘Top 10 food packaging bag Manufacturers and Suppliers in China’, highlighting the industry’s leaders, including Shantou Kaixuan Packaging Co., Ltd. Explore quality, innovative and sustainable food packaging solutions from these renowned manufacturers. Trust in their excellence to meet your food packaging needs.

Latest Trends and Innovations in the Food Packaging Bag Industry

Latest Trends and Innovations in the Food Packaging Bag Industry Introduction:The food packaging bag industry is constantly evolving to meet changing consumer demands, technological advancements, and sustainability goals. Staying updated with the latest trends and innovations in food packaging bags is crucial for manufacturers to remain competitive and meet the dynamic needs of the market….

Choosing the Ideal Vacuum-Sealed Food Packaging Bag

Choosing the Ideal Vacuum-Sealed Food Packaging Bag Introduction:Vacuum-sealed food packaging bags have gained popularity due to their ability to extend the shelf life of food products, preserve freshness, and prevent spoilage. Selecting the ideal vacuum-sealed food packaging bag is crucial to ensure product quality, safety, and optimal functionality. This article provides insights into the key…

Balancing Functionality and Convenience in Food Packaging Bags

Balancing Functionality and Convenience in Food Packaging Bags Food packaging bags serve multiple purposes, from protecting and preserving food products to providing convenience and ease of use for consumers. Striking the right balance between functionality and convenience is crucial in designing food packaging bags that meet the needs of both manufacturers and consumers. This article…

Hygiene Standards and Food Safety in Food Packaging Bags

Hygiene Standards and Food Safety in Food Packaging Bags Introduction:Maintaining high hygiene standards and ensuring food safety are primary concerns in the production and use of food packaging bags. Contamination and improper handling can lead to serious health risks for consumers. This article delves into the importance of hygiene standards in food packaging bags and…

Design and Healthcare Requirements of Food Packaging Bags

Design and Healthcare Requirements of Food Packaging Bags Food packaging bags play a crucial role in protecting and preserving the quality, safety, and integrity of food products. Designing food packaging bags that meet healthcare requirements is essential to ensure the prevention of contamination, proper labeling, and effective use. This article explores the key considerations and…