Composite Film-Food Packaging Another Leap

Composite Film-Food Packaging Another Leap

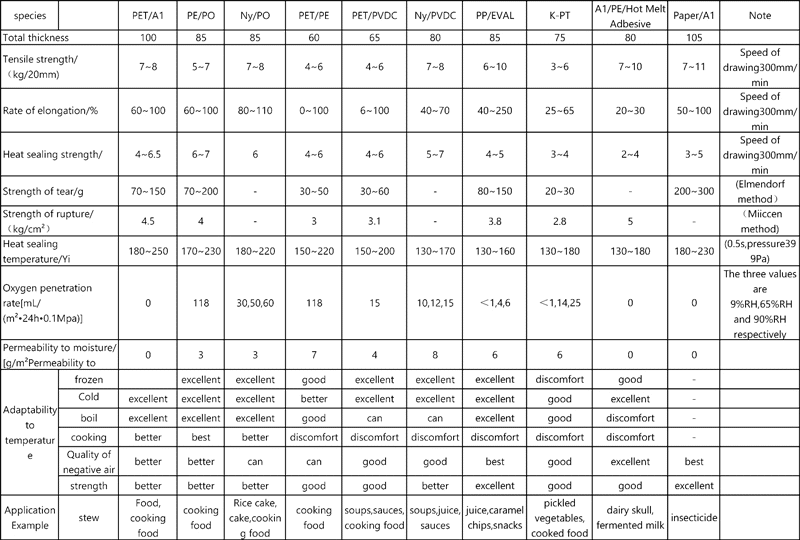

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, can be used in a certain range, but a single material can not have all the properties of packaging materials, can not meet the overall requirements of food packaging.

Therefore, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

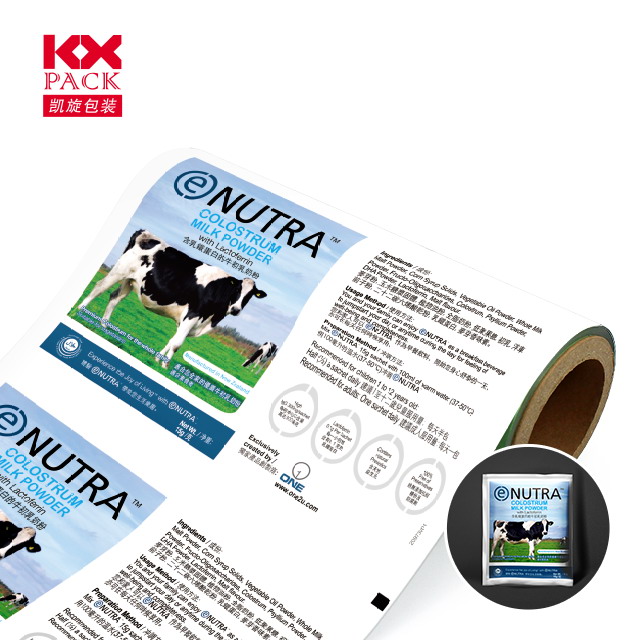

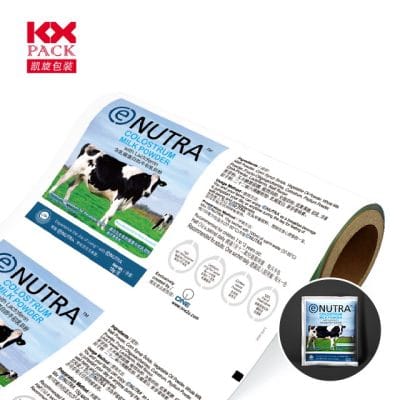

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

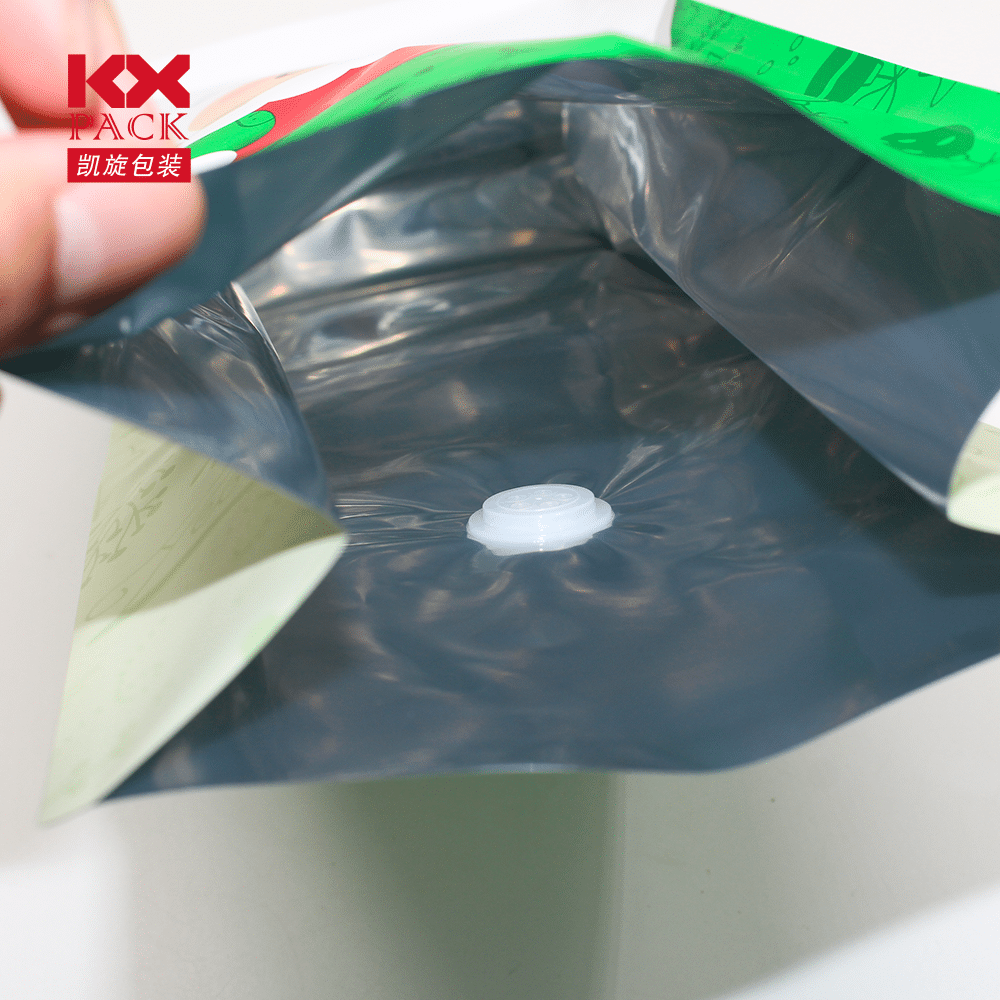

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: non-toxic, tasteless, oil resistance, chemical resistance

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, PET, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

For example: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

How to customize good recycle composite film with us?

Shantou Kaixuan Packaging Co.,Ltd

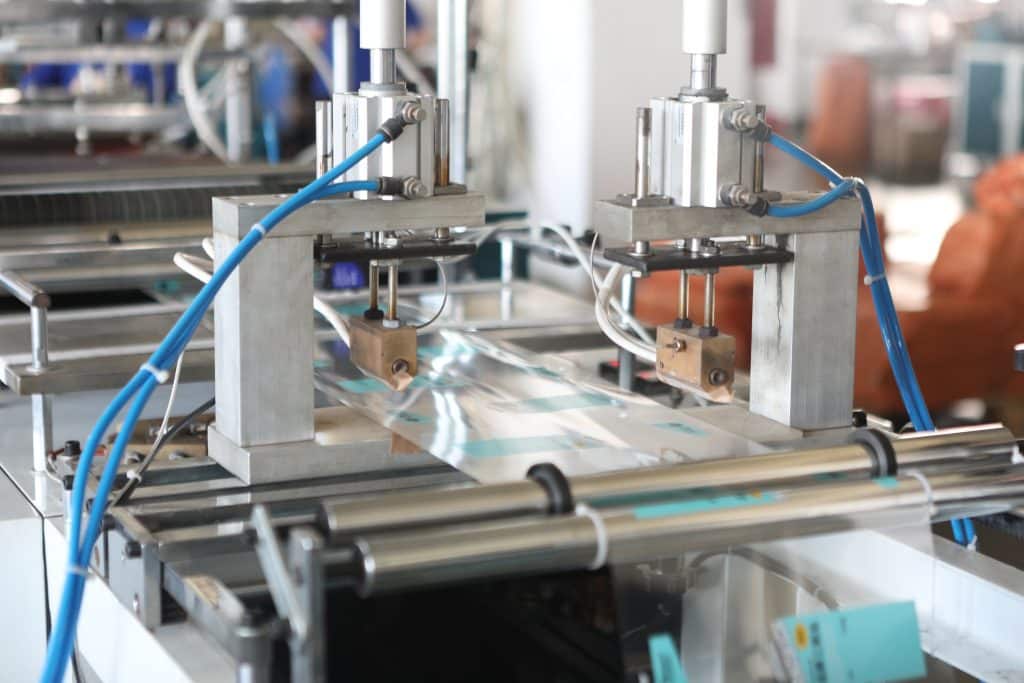

Direct manufactory focus on packaging over 20 years,expecially in color printing,blister and bag making.Integrated in design,production and sale.Kaixuan factory covers an area of 20000㎡,equipped with a 10000 level dust-free workshop,300m/min 12 color high-speed gravure printing machine,automatic high-speed blister machine with German technology,eight side sealing bag making machine and other high-standard bag making equipment.

No Benzene No Ketone Ink.Meanwhile, we using benzene free and ketone free,ink and other eco-fridendly materials.The daily capacity could reach 150 tons,absolutely meet your needs in Safe,Efficient and Healthy.

We accept customized orders.In order to offer you a correct quotation,we should need your details as below:

- Qty

- Printing color design

- Materials and thickness

- Size

For more detailed types or questions about food packaging films, please refer to: https://kxpack.com/product-category/plastic-film/

We provide but are not limited to high-quality products, competitive prices, excellent service, etc.