Milk Packaging Film: Innovation, Sustainability, and the Future of Dairy Packaging

Milk Packaging Film

Milk, a staple in households worldwide, relies heavily on advanced packaging solutions to maintain freshness, safety, and nutritional value. Among these solutions, milk packaging films have emerged as a cornerstone of modern dairy logistics, balancing functionality, cost-efficiency, and environmental responsibility. This blog explores the evolution of milk packaging films, their technical advancements, and the sustainable trends shaping their future.

The Science Behind Milk Packaging Films

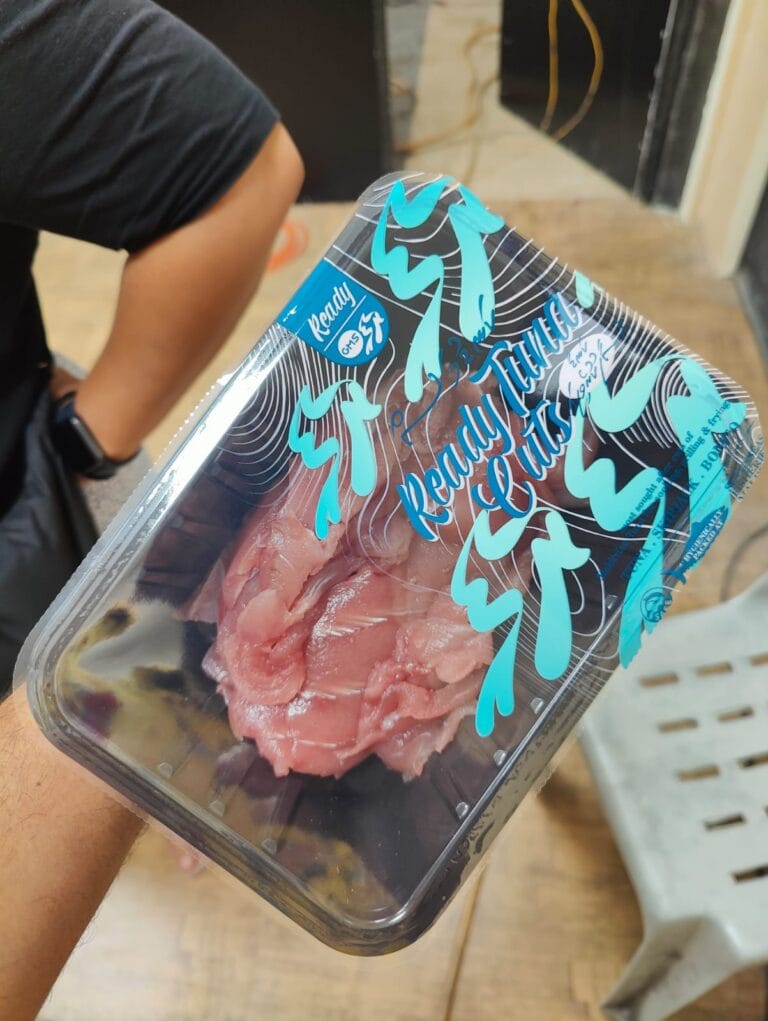

Milk packaging films are engineered to address the unique challenges of dairy preservation. Unlike rigid containers like glass or metal, flexible films offer lightweight, space-saving benefits while maintaining critical barriers against oxygen, light, and moisture—all of which can degrade milk quality.

Material Composition:

Modern milk packaging films are typically multi-layer structures, combining polymers such as:

- LDPE (Low-Density Polyethylene): Provides flexibility and heat-sealability.

- LLDPE (Linear Low-Density Polyethylene): Enhances puncture resistance and reduces leakage (leakage rates drop from 1–5% with LDPE to 0.6% with LLDPE).

- EVOH (Ethylene Vinyl Alcohol): A high-barrier resin that blocks oxygen, extending shelf life to 90 days under room temperature.

- Nylon or Polyamide: Adds strength and resistance to tearing.

- Calcium Carbonate: Incorporated in some films to reduce material usage by up to 40% while maintaining structural integrity.

These layers are co-extruded or laminated, creating a composite film that balances cost, performance, and sustainability. For example, a 50:50 blend of LDPE (MFI 0.5) and octene-based LLDPE (MFI 1.0) is now a standard for liquid milk pouches, optimizing both yield and durability.

Key Innovations Driving Performance

- High-Barrier Aseptic Films:

Films incorporating EVOH or vacuum-aluminized layers provide superior oxygen resistance, enabling UHT (Ultra-High Temperature) milk to stay fresh without refrigeration for months. This technology is critical for markets with limited cold-chain infrastructure. - Light-Blocking Properties:

Black masterbatches in the inner layer of films block UV and visible light, preventing nutrient degradation (e.g., vitamin B2 loss) and off-flavors. - Down-Gauging and Yield Optimization:

Manufacturers are reducing film thickness by 1–2 microns, increasing the number of pouches per kilogram of raw material. For instance, a 1-micron reduction yields 9 additional half-liter pouches per kg. - Smart and Active Packaging:

Emerging technologies include:- Nanotechnology: Enhancing barrier properties by embedding clay nanoparticles in polymer matrices.

- Antimicrobial Coatings: Incorporating silver ions or natural extracts to inhibit bacterial growth.

- Freshness Indicators: Time-temperature sensors that change color if milk is exposed to unsafe conditions.

Sustainability: The Path Forward

The dairy industry faces mounting pressure to reduce plastic waste. Milk packaging films are evolving to meet this challenge:

- Recyclable and Bio-Based Materials:

- Mono-Material Films: Designed for easier recycling, these films use a single polymer type (e.g., PE) instead of multi-layer blends.

- Biodegradable Polymers: Films made from PLA (Polylactic Acid) or starch blends are gaining traction, though challenges remain in barrier performance and cost.

- Lightweighting and Resource Efficiency:

Innovations like calcium carbonate-filled films cut material use by 40%, while down-gauging reduces raw material consumption. Abel & Cole’s partnership with ReLondon highlights how lifecycle assessments can guide eco-friendly material choices. - Edible Packaging:

Researchers are exploring milk protein-based films (e.g., casein or whey) as edible, biodegradable alternatives. These films offer excellent oxygen barriers but require breakthroughs in moisture resistance to compete with plastics.

Consumer Preferences and Market Trends

- Convenience: Pouches with air-filled handles and flat bottoms (e.g., XL Plastics’ design) are gaining popularity for their spill-proof pouring and stability.

- Transparency: Some brands are adopting transparent windows in films to showcase product quality, though this requires advanced UV-blocking layers.

- Circular Economy: Initiatives like glass bottle return programs coexist with film-based solutions, catering to diverse consumer segments.

The Future of Milk Packaging Films

The next decade will likely see:

- Widespread Adoption of Smart Packaging: Real-time freshness monitoring via QR codes or embedded sensors.

- Scalable Bio-Based Films: Overcoming current limitations in cost and performance to replace conventional plastics.

- Global Standardization: Harmonizing recycling codes and material specifications to streamline waste management.

Conclusion

Milk packaging films are a testament to how material science and sustainability can coexist. From multi-layer barriers to edible prototypes, the industry is innovating to meet consumer demands while reducing its environmental footprint. As brands like Abel & Cole lead the charge in carbon footprint analysis, the future of dairy packaging looks both functional and green.

What’s your take on the evolution of milk packaging? Share your thoughts in the comments below! 🥛✨