Paggalugad sa mundo ng mga sealing films: Mga Innovations at Application (5)

Sealing Films

In the realm of materials science and packaging technology, sealing film have emerged as a cornerstone for ensuring product integrity, kaligtasan, at pag -andar sa iba't ibang mga industriya. Mula sa solar cell encapsulation hanggang sa sealing microplate ng laboratoryo, Ang maraming nalalaman na pelikula ay naglalaro ng isang mahalagang papel sa mga modernong proseso ng pagmamanupaktura at pananaliksik.

Sealing Films in Solar Cell Technology

One groundbreaking application of sealing film lies in the photovoltaic sector. According to a patent published in 2021, solar cell sealing films are engineered to inhibit corrosion of lead wires and electrodes, thereby preserving the high power generation efficiency of solar cells over extended periods. These films typically comprise an ethylene/vinyl acetate (Eva) copolymer matrix, crosslinking agents, and acid acceptors. Halimbawa, back-side sealing films contain acid acceptors at concentrations of 0.5 parts by mass or higher per 100 parts of EVA, ensuring robust protection against environmental degradation.

Laboratory Applications: Microplate Sealing Films

In research laboratories, sealing film are indispensable for preserving sample integrity during experiments. Mga pelikulang tulad ng MicroBurst revolutionize microplate sealing by encapsulating adhesive in microspheroids, preventing premature sticking to gloves. Once positioned correctly, pressure activates the adhesive, forming a durable, optically clear seal that withstands thermal cycling—ideal for PCR work. Ganun din, products like ThermalSeal® at AlumaSeal® offer heat-resistant and aluminum foil-based solutions for 96-well and 384-well plates, ensuring sample security during storage and processing.

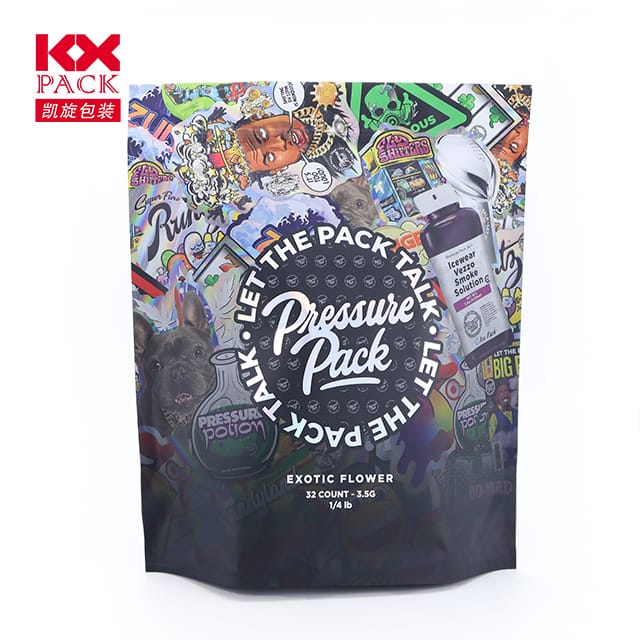

Industrial and Consumer Packaging

Beyond labs and solar cells, sealing films are ubiquitous in packaging. Heat-sealing films for food, medical, and pharmaceutical applications employ multilayer structures, including gas barrier layers and thermosealing copolymers (Hal., ethylene-methacrylic acid). These films ensure product freshness, tamper resistance, at pagsunod sa mga pamantayan sa regulasyon. Halimbawa, LDPE self-sealing films with sealing grooves, developed in the 1990s, demonstrated enhanced adhesion and cut-off precision in shrink-wrap packaging.

Mga Innovations na nagmamaneho sa hinaharap

Recent advancements focus on sustainability and functionality. Researchers are exploring bio-based polymers and recyclable materials to reduce environmental impact. Samantala, Mga pelikulang tulad ngeXTReme™ Seal Film offer universal compatibility with various plate types, streamlining workflows in high-throughput screening.

Konklusyon

Sealing film represent a convergence of material science, engineering, at pagbabago. From safeguarding solar cells to enabling precise laboratory experiments, these films underscore the importance of protective barriers in modern technology. As industries continue to push boundaries, the evolution of sealing films will likely focus on enhancing performance, pagpapanatili, at kakayahang magamit.

What are your thoughts on the future of sealing film? Share your insights in the comments below!