Paano makontrol ang kaligtasan ng mga pelikulang packaging ng pagkain?

Para sa mga exporters na nagpapadala ng mga namamatay na pagkain sa ibang bansa, Ang pagpili ng tamang mga film ng packaging ng pagkain ay mahalaga sa pagpapanatili ng kaligtasan ng produkto at pagpapalawak ng istante-buhay. Kapag pumipili ng mga pelikulang packaging ng pagkain, Isaisip ang mga patnubay na ito:

Gamit ang mga high-barrier films:

Maghanap para sa mga high-barrier films na humaharang sa oxygen, kahalumigmigan, at ilaw upang mapanatili ang pagiging bago at maiwasan ang kontaminasyon. Kasama sa mga karaniwang hadlang ang aluminyo, Metallized Polyesters, at mga coatings ng silikon oxide. Pinipigilan din ng mga high-barrier films ang pagtagas at paganahin ang binagong packaging ng kapaligiran. Kumunsulta sa iyong tagapagtustos ng pelikula upang makilala ang isang perpektong film ng hadlang para sa iyong uri ng pagkain.

Tiyakin ang mga materyales na grade sa pagkain:

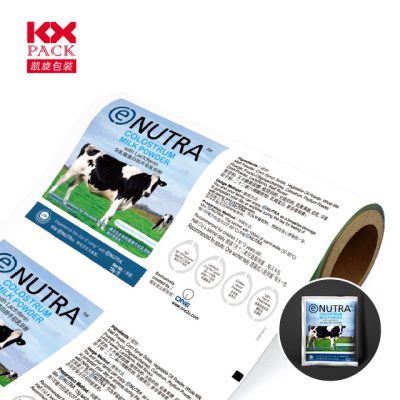

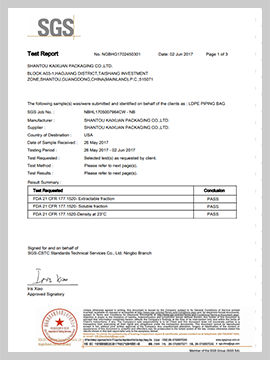

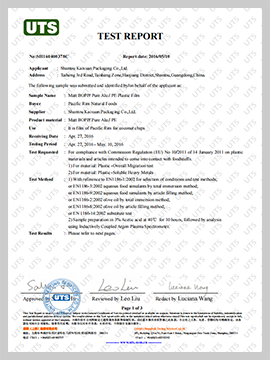

Patunayan na ang lahat ng mga materyales sa packaging ay grade-grade at libre mula sa mga mapanganib na kemikal. Ang mga pelikula ay dapat na sumusunod sa FDA at EU para sa direktang pakikipag -ugnay sa pagkain. Plastik tulad ng polyethylene, Ang polypropylene at PET ay karaniwang ginagamit. Hilingin sa iyong tagapagtustos na magbigay ng mga sertipikasyon sa kaligtasan.

Suriin ang mga rating ng temperatura:

Itugma ang rating ng temperatura ng pelikula sa iyong mga kinakailangan sa produkto. Karamihan sa mga pelikulang pagkain ay gumagana para sa frozen na imbakan, habang ang mga dalubhasang high-temperatura na pelikula ay huminto sa mga proseso ng pasteurization o retort. Ang paggamit ng maling temperatura ng pelikula ay maaaring mag -distort ng packaging at ilantad ang pagkain.

Paliitin ang pagkamatagusin ng oxygen:

Ang mas mababang mga rate ng paglipat ng oxygen ay makakatulong na mapanatili ang pagiging bago. Para sa mga pagkaing may mataas na taba tulad ng karne, Ang mga pelikulang may permeability ng oxygen sa ibaba ng 2cc/m2/24hr sa 73 ° F ay makakatulong na maiwasan ang rancidity. Ang mga oxygen scavengers at vacuum packaging ay nagbabawas din ng pagkakalantad sa oxygen.

Application ng Food Packaging Mga Pelikula

Ang mga pelikulang packaging ng pagkain ay nagbibigay ng magaan, nababaluktot, at mataas na pagganap na hadlang laban sa kontaminasyon para sa naproseso at sariwang pagkain. Narito ang ilan sa mga pinaka -karaniwang aplikasyon ng mga pelikulang packaging ng pagkain sa iba't ibang mga industriya:

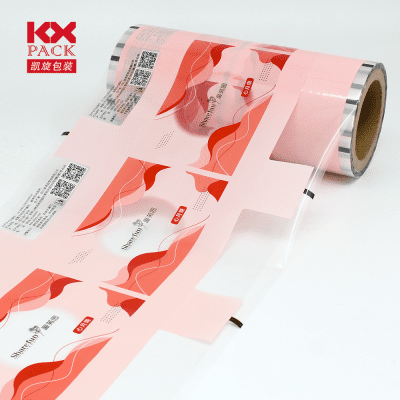

Mga pagkaing meryenda

Mga chips ng patatas, NUTS, at iba pang malutong na meryenda ay karaniwang gumagamit ng mga multilayered polypropylene films. Ang mga pelikulang ito ay may mahusay na kalinawan, lakas ng makunat, at pag -abuso sa pag -abuso upang mapanatili ang crispness. Nagbibigay din ang mga pelikulang Bopp ng Metallized.

Naproseso na karne

Ang mga vacuum pouch at pag-urong ng mga bag na may mga pelikulang may mataas na barrier ay mainam para sa mga naproseso na karne tulad ng mga sausage at mga hiwa ng deli. Pinipigilan nila ang pagkakalantad ng oxygen upang limitahan ang lipid oxidation at rancid flavors. Ang mga pelikulang ito ay sumunod din nang mahigpit upang mai -seal sa mga juice at mapanatili ang pagiging bago.

Keso & Pagawaan ng gatas

Ang keso ay nangangailangan ng nakamamanghang, Ang mga pelikulang Porous PE na naghihigpitan sa pagkawala ng kahalumigmigan habang pinapayagan ang CO2 at Oxygen Exchange. Ang mga alagang hayop at specialty coated films ay nagbibigay ng mas mataas na hadlang sa oxygen at CO2 upang pahabain ang buhay ng istante. Para sa mantikilya at kumakalat, Ang mga foil ng aluminyo ay humarang sa oxygen at ilaw upang maiwasan ang oksihenasyon.

Sariwang ani

Ang mga pelikulang polyethylene ay nagpapanatili ng pinakamainam na antas ng kahalumigmigan at maiwasan ang paghalay ng kahalumigmigan para sa mga prutas at gulay. Ang mga anti-fog films ay patuloy na gumagawa ng hitsura ng sariwa. Perforated Films Balanse moisture control na may gas exchange upang mabagal ang paghinga.

Mga frozen na pagkain

Ang mga mababang-temperatura na polyolefin films ay nagpapanatili ng kakayahang umangkop at epekto ng paglaban sa mga nagyeyelong temperatura. Pinipigilan ng mga hadlang ng singaw ng mataas na tubig ang mga burn ng freezer. Ang mga pelikulang may mataas na mainit na tacks ay nagpapanatili ng mahigpit na mga frozen na pagkain.