Ang mga intricacies ng packaging film manufacturing: Isang Paggalugad na Hinihimok ng Proseso (3)

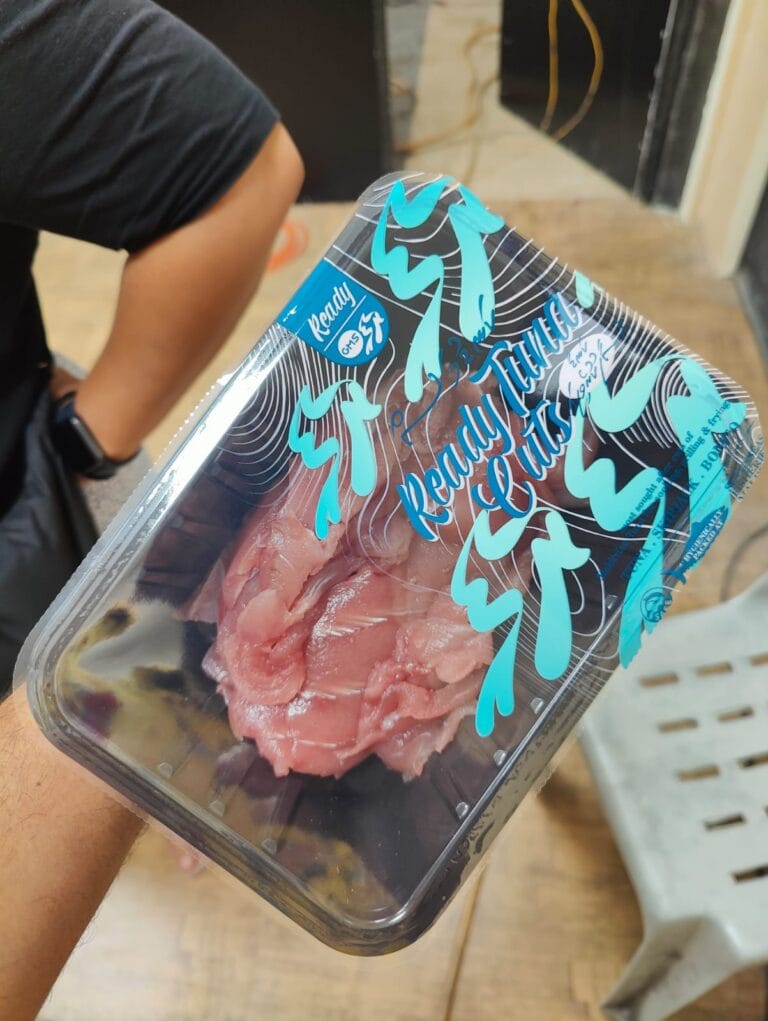

Packaging film

Sa larangan ng modernong packaging, Ang paggawa ng mga film ng packaging ay nakatayo bilang isang pundasyon ng pagbabago at kahusayan. Mula sa kaligtasan ng pagkain hanggang sa pangangalaga ng produkto, Ang kalidad at pag -andar ng mga pelikula ng packaging ay direktang nakakaapekto sa tiwala ng consumer at reputasyon ng tatak. Ang blog na ito ay sumasalamin sapackaging film manufacturing process, Pag -highlight ng mga pangunahing yugto, mga pagsulong sa teknolohiya, and quality control measures that define this dynamic industry.

1. Material Selection and Preparation

The journey begins withraw material selection, a critical step that determines the film’s physical properties and application suitability. Polyethylene (PE), including high-density (HDPE) and low-density (LDPE), remains a staple due to its flexibility, Cost-pagiging epektibo, and recyclability. Advanced formulations may incorporateethylene-vinyl acetate (Eva) copolymers omultilayer co-extrusion techniques to enhance barrier properties, katatagan, or heat resistance. Halimbawa, EVA-based films with 9–26% vinyl acetate content are engineered for vacuum packaging, offering high stretch ratios without compromising integrity.

2. Extrusion and Film Formation

The heart of the process lies inextrusion, where resin pellets are melted and forced through a die to form a continuous film. Modern extrusion lines employco-extrusion teknolohiya, enabling the simultaneous creation of multi-layered films with distinct functionalities—e.g., a barrier layer for oxygen resistance and a sealant layer for heat sealing. Key parameters such astemperatura, presyon, and screw speed are meticulously controlled to ensure uniform thickness and molecular orientation.

3. Printing and Surface Enhancement

Aesthetics and branding come into play duringPagpi -print, where techniques likeFlexography (for high-speed, multi-color jobs) oUV printing (for vibrant, instant-dry graphics) add visual appeal. UV printing, sa partikular, offers1440 dpi precision and 5-year fade resistance, making it ideal for luxury packaging. Post-printing, surface treatments tulad ngpaglalamina, Embossing, or metallization enhance durability, tactile appeal, or barrier properties.

4. Lamination and Composite Bonding

For multi-layer structures, paglalamina fuses different films or substrates (Hal., papel, aluminyo foil) using adhesives or thermal bonding.Dry lamination uses heat and pressure, habangwet lamination employs solvent-based adhesives. A 2021 study highlighted the challenge ofvolatile organic compound (VOC) migration in solvent-based adhesives, prompting manufacturers to adoptin-process VOC monitoring with portable sensors. This ensures compliance with food-safety regulations and reduces environmental impact.

5. Slitting, Winding, and Finishing

The final film isslit into desired widths andwound onto rolls or spools. Automated systems adjust tension and speed to prevent defects liketelescoping owrinkling. Quality checks at this stage includethickness measurement, tensile strength testing, and optical inspection to detect pinholes or inconsistencies.

6. Quality Control and Innovation

Industriya 4.0 technologies are transforming quality control.IoT sensors embedded in machinery track real-time data on temperature, presyon, and line speed, enabling predictive maintenance and defect reduction. Halimbawa, a 2025 study demonstrated how IoT-driven analysis of five parameters reduced quality defects in packaging film production by 30%. Bukod pa rito, sustainability initiatives drive the adoption ofBiodegradable Polymers atNilalaman ng recycled, aligning with global eco-conscious trends.

Konklusyon: The Future of Packaging Film Manufacturing

The packaging film industry is poised for growth, hinimok ngautomation, pagpapanatili, and consumer demand for high-performance packaging. As technologies likeAI-driven defect detection atnano-layered barriers emerge, manufacturers must balance innovation with regulatory compliance and environmental stewardship. By mastering the manufacturing process—from material selection to final inspection—companies can deliver films that not only protect products but also elevate brands in a competitive marketplace.

Stay tuned for more insights into packaging innovations and industry trends! 🌍📦✨

Mga keyword: Packaging Film Manufacturing, Extrusion, Pagpi-print, Lamination, KONTROL CONTROL, Pagpapanatili, IoT, UV Printing