Komposittfilm-matemballasje Nok et sprang

Komposittfilm-matemballasje Nok et sprang

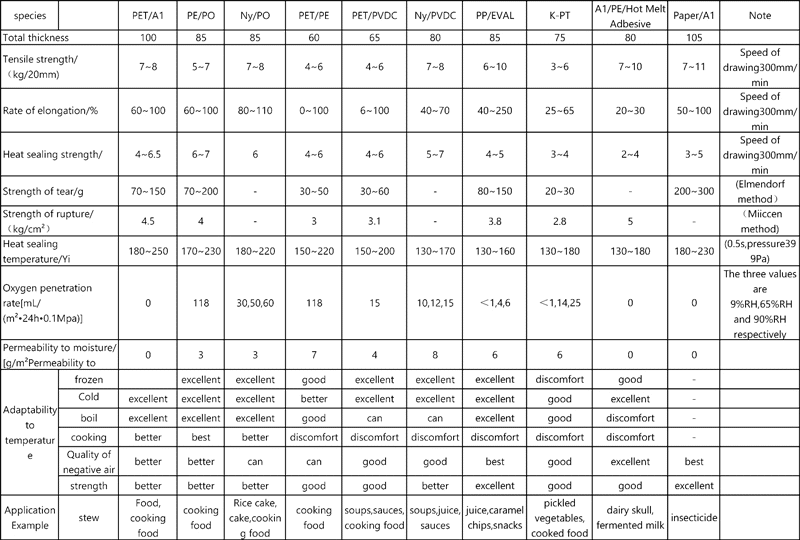

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, kan brukes i et visst område, men et enkelt materiale kan ikke ha alle egenskapene til emballasjematerialer, kan ikke oppfylle de generelle kravene til matemballasje.

Derfor, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

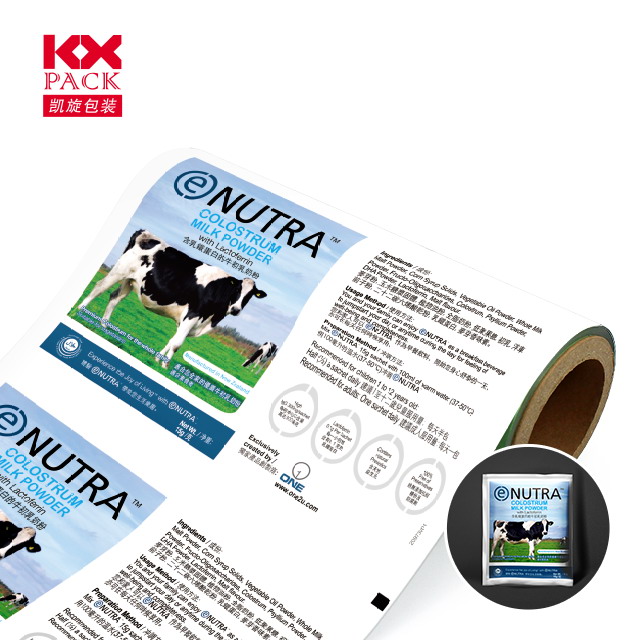

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

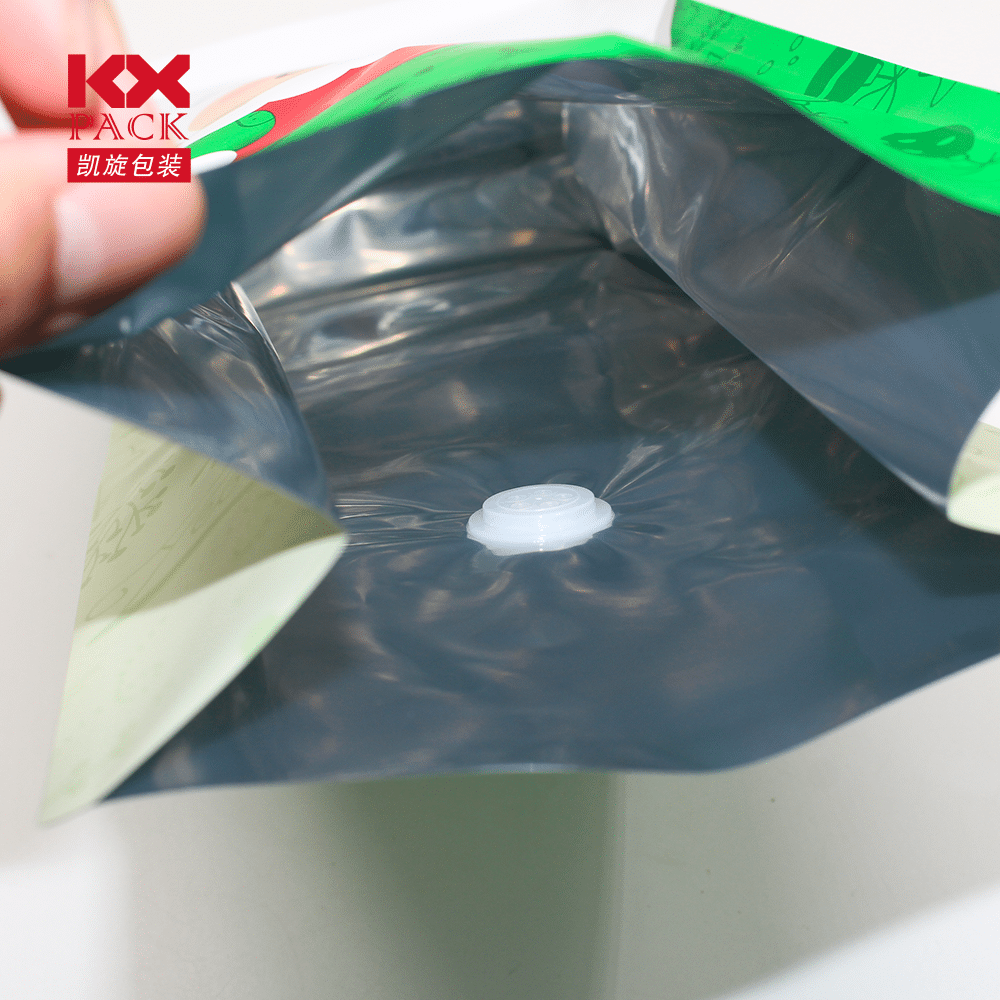

- Inner layer requirements: ikke-giftig, tasteless, oil resistance, chemical resistance

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, KJÆLEDYR, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

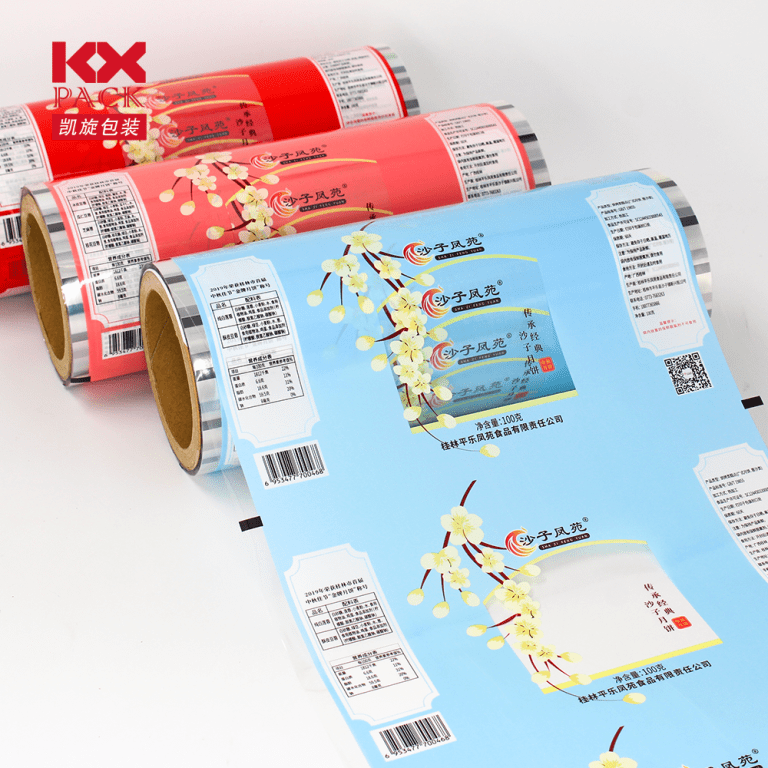

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

For eksempel: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

How to customize good recycle composite film with us?

Shantou Kaixuan Packaging Co.,Ltd

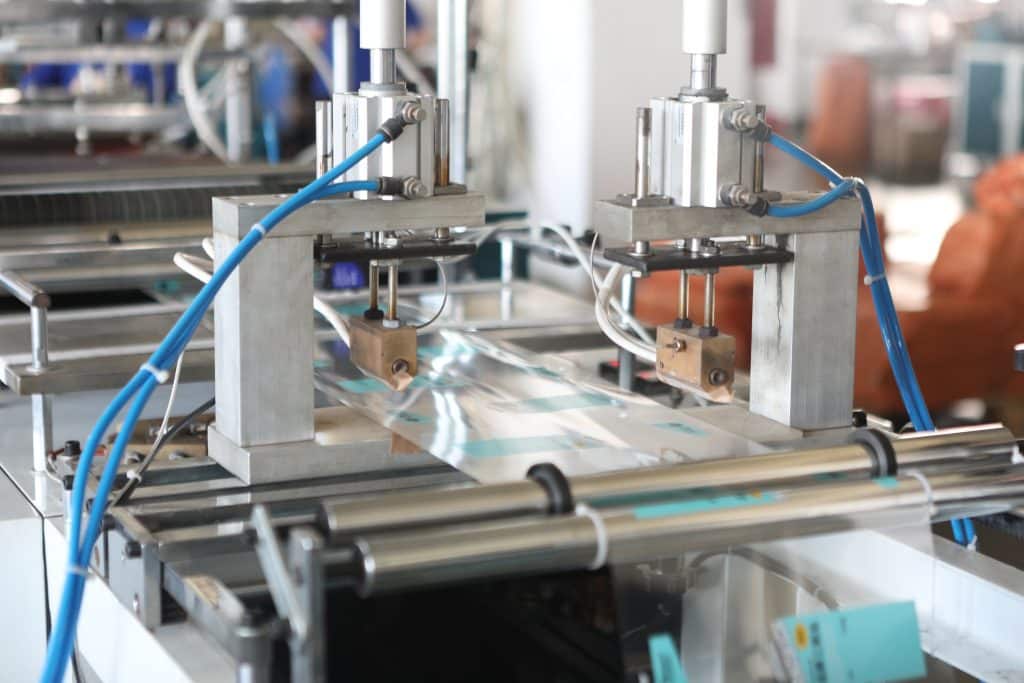

Direkte fabrikkfokus på emballasje over 20 år,spesielt i fargetrykk,blister og poser. Integrert i design,produksjon og salg. Kaixuan fabrikken dekker et område på 20000㎡,utstyrt med en 10000 nivå støvfritt verksted,300m/min 12 farge høyhastighets dyptrykkmaskin,automatisk høyhastighets blistermaskin med tysk teknologi,åtte siders forseglingsmaskin for posefremstilling og annet posefremstillingsutstyr av høy standard.

Ingen benzen Ingen ketonblekk. I mellomtiden, vi bruker benzenfri og ketonfri,blekk og andre miljøvennlige materialer.Den daglige kapasiteten kan nå 150 tonn,oppfyller absolutt dine behov i Safe,Effektiv og sunn.

Vi aksepterer tilpassede bestillinger. For å kunne tilby deg et korrekt tilbud,vi burde trenge opplysningene dine som nedenfor:

- Antall

- Utskrift farge design

- Materialer og tykkelse

- Størrelse

For mer detaljerte typer eller spørsmål om matemballasjefilmer, Vennligst se: https://kxpack.com/product-category/plastic-film/

Vi tilbyr, men er ikke begrenset til, produkter av høy kvalitet, konkurransedyktige priser, utmerket service, etc.