Anwendung und Entwicklung von Stand-up-Beuteln in der flexiblen Verpackungsindustrie

Anwendung und Entwicklung von Stand-up-Beuteln in der flexiblen Verpackungsindustrie

Die Kaufkraft der Menschen für schnelldrehende Konsumgüter wächst weiter, und die rasante Entwicklung des Marktes für schnelllebige Konsumgüter hat auch zum Aufstieg der flexiblen Verpackungsindustrie geführt. Heutzutage, Die Arten und Verwendungsmöglichkeiten von Verpackungsbeuteln sind sehr vielfältig. Gleichzeitig, Auch eine gute Verpackung kann ein hochwertiges Image des Produkts vermitteln, die Wettbewerbsfähigkeit des Produkts verbessern, und so den Produktabsatz fördern.

ICH. Arten und Anwendungsvorteile von Standbodenbeuteln

Standbodenbeutel für Bekleidungsverpackungen

Standbeutel für Lebensmittelverpackungen

Es gibt viele Verpackungsklassifizierungen für Produkte. Nach technischer Klassifizierung, Sie können in feuchtigkeitsbeständige Verpackungen unterteilt werden, wasserdichte Verpackung, schimmelresistente Verpackung, Frischhalteverpackung, Schnellgefrierverpackung, atmungsaktive Verpackung, Mikrowellen-Sterilisationsverpackung, aseptische Verpackung, aufblasbare Verpackung, Vakuumverpackung, Desoxidation Verpackung, Blisterverpackung, Skin-Verpackung, Stretchverpackung, Retortenverpackung, usw.

Die oben genannten verschiedenen Verpackungsbeutel bestehen alle aus unterschiedlichen Verbundmaterialien, und ihre Verpackungseigenschaften entsprechen den Anforderungen verschiedener Produkte und können die Qualität und stabile Funktion der Produkte selbst effektiv aufrechterhalten.

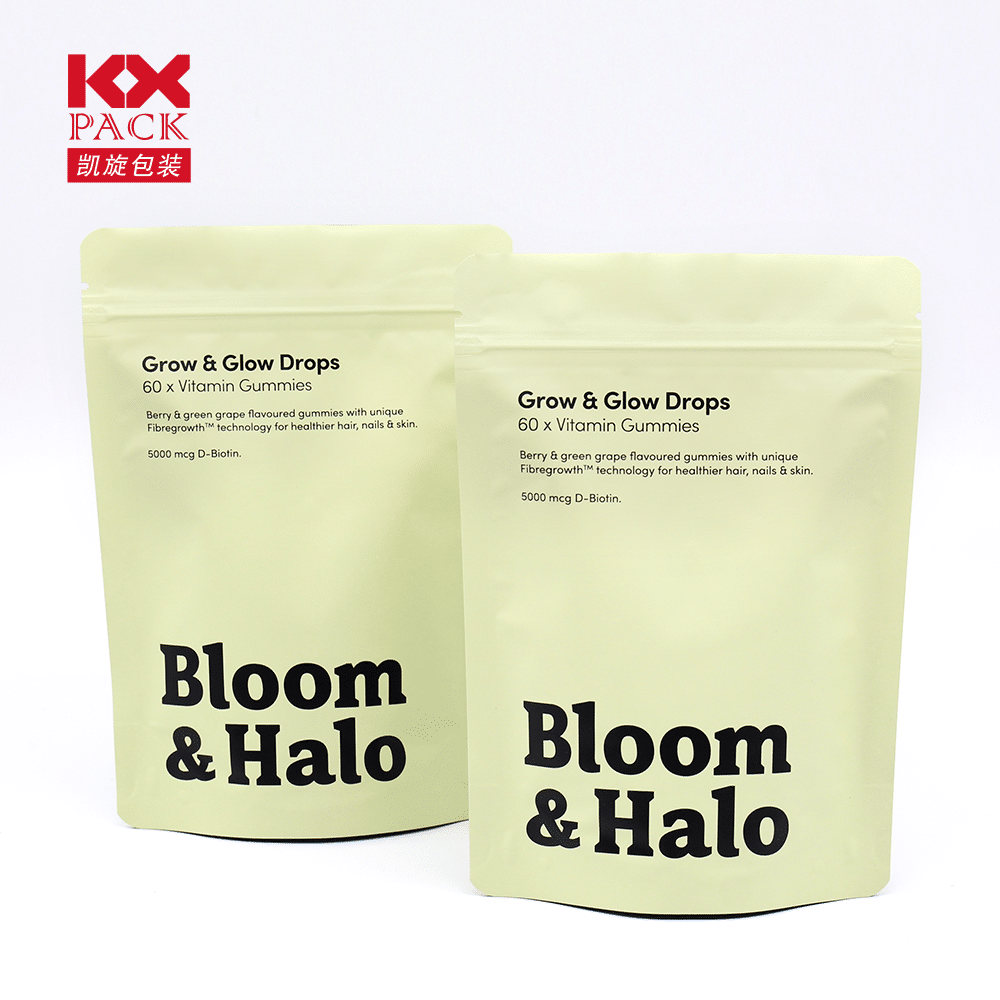

Standbodenbeutel gelten als Klassiker moderner Verpackungen, und es ist auch eine relativ neue Verpackungsform. Es bietet in vielerlei Hinsicht gewisse Vorteile, beispielsweise bei der Verbesserung der Produktqualität, Verstärkung der optischen Wirkung von Regalen, Licht tragen, einfach zu bedienen, wasserdicht, feuchtigkeitsbeständig, Oxidationsbeständig, und Verkäuflichkeit.

Standbodenbeutel können in fünf Typen unterteilt werden: gewöhnliche Standbodenbeutel, Standbodenbeutel mit Düse, Standbeutel mit Reißverschluss, mundähnliche Standbeutel, und speziell geformte Standbodenbeutel. Wird hauptsächlich in Fruchtsaftgetränken verwendet, Gewürze, Kleidung, Hardware und Elektronik, Reinigungsmittel, Kosmetika und andere Produkte.

Produkte, die in Standbodenbeuteln verpackt sind, sind für den Verbraucher sehr praktisch, weil es Plastiktüten sind, die leicht sind und nicht leicht beschädigt werden können. Zusätzlich, Der Reißverschluss-/Knochen-Standbeutel kann wiederverwendet werden, Der Standbeutel mit Ausguss macht das Ausgießen von Lebensmitteln bequemer, und der exquisite Druck kann dazu beitragen, dass das Produkt die Aufmerksamkeit der Verbraucher auf sich zieht.

Standbeutel werden im Allgemeinen mit einer PET/FOIL/PET/PE-Struktur laminiert, und kann auch haben 2 Schichten, 3 Schichten und andere Spezifikationen. Abhängig von den unterschiedlichen Produkten im Paket, Bei Bedarf kann eine Sauerstoffbarriere-Schutzschicht hinzugefügt werden, um die Sauerstoffdurchlässigkeit zu reduzieren und die Haltbarkeit des Produkts zu verlängern.

Gewöhnliche Standbeutel und allgemeine Standbeutel haben die Form von vier Siegelkanten, die nicht wieder verschlossen und wiederholt geöffnet werden kann; Standbodenbeutel mit Saugdüsen eignen sich besser zum Entleeren oder Aufsaugen des Inhalts, und kann wiederholt wieder verschlossen und geöffnet werden, die als Standbodenbeutel und Standbodenbeutel betrachtet werden können.

Kombination aus gewöhnlichem Flaschenmund; Der mundähnliche Standbeutel vereint den Komfort eines Standbeutels mit Saugdüse und die Kostengünstigkeit eines gewöhnlichen Standbeutels, das ist, Die Funktion der Saugdüse wird durch die Form des Beutels selbst realisiert, Der mundartige Standbeutel lässt sich jedoch nicht wiederversiegeln; Bei speziell geformten Standbeuteln handelt es sich um neue Standbeutel in verschiedenen Formen, die durch Änderung der herkömmlichen Beutelform entsprechend den Anforderungen des Produkts hergestellt werden, wie Taillendesign, Bodenverformungsdesign, Griffdesign, usw.

Gewöhnliche Standbeutel und allgemeine Standbeutel haben die Form von vier Siegelkanten, die nicht wieder verschlossen und wiederholt geöffnet werden kann; Standbodenbeutel mit Saugdüsen eignen sich besser zum Entleeren oder Aufsaugen des Inhalts, und kann wiederholt wieder verschlossen und geöffnet werden, die als Standbeutel und Kombination aus gewöhnlichen Flaschenmündungen betrachtet werden können.

Der mundähnliche Standbeutel vereint den Komfort eines Standbeutels mit Saugdüse und die Kostengünstigkeit eines gewöhnlichen Standbeutels, das ist, Die Funktion der Saugdüse wird durch die Form des Beutels selbst realisiert, Der mundartige Standbeutel kann jedoch nicht wiederholt versiegelt werden.

Der speziell geformte Standbeutel ist ein neuer Standbeutel in verschiedenen Formen, der durch Änderung der traditionellen Beutelform entsprechend den Anforderungen des Produkts hergestellt wird, wie Taillendesign, Bodenverformungsdesign, Griffdesign, usw.

II. Drei häufige Qualitätsprobleme von Standbodenbeuteln

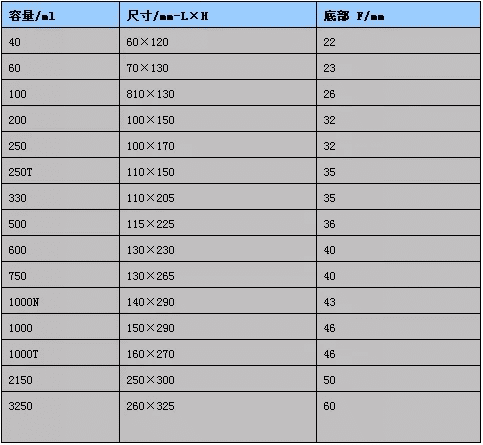

Standbodenbeutel in üblicher Größe

Undichtigkeit des Standbeutels

Der Grund für die Undichtigkeit des Standbodenbeutels liegt hauptsächlich in der Auswahl der Verbundmaterialien und der Festigkeit der Heißsiegelung.

①Materialauswahl

Die Materialauswahl des Standbodenbeutels ist sehr wichtig, um ein Auslaufen zu verhindern, Der Zweck besteht darin, die Schälfestigkeit zwischen der Außenschicht und der mittleren Barriereschicht zu verbessern, die Barriereschicht und das Material der Heißsiegelschicht sowie die Heißsiegelfestigkeit des Beutels. daher, Es ist erforderlich, dass die Oberflächenspannung der Verbundoberfläche der Folie mehr als 38 dyn/cm beträgt; Die Heißsiegelleistung der inneren Heißsiegelfolie bei niedrigen Temperaturen ist besser, und die Oberflächenspannung der Wärmeabdeckung muss weniger als 34dyn/cm betragen; Fester, niedrigviskoser Klebstoff, hochreines organisches Lösungsmittel.

②Heißsiegelfestigkeit

Auch eine geringe Heißsiegelfestigkeit ist einer der wichtigen Faktoren, die das Auslaufen von Standbeuteln beeinflussen. Beim Heißsiegeln, die passende Beziehung zwischen der Heißsiegeltemperatur, Heißsiegeldruck und Heißsiegelzeit sollten angepasst werden. Insbesondere, Wir sollten auf die Heißsiegeltemperatur von Beuteln mit unterschiedlichen Strukturen achten. Denn die Schmelzpunkte verschiedener Arten von Kunststofffolien sind unterschiedlich, Auch die Heißsiegeltemperatur ist unterschiedlich; Die Schicht wird im geschmolzenen Hochtemperaturzustand durch das Heißsiegelmesser geschert, was die Siegelfestigkeit verringert.

Zusätzlich, Die vierschichtige Versiegelung am Boden des Standbodenbeutels ist der kritischste Teil, und die Heißsiegeltemperatur, Heißsiegeldruck und Heißsiegelzeit können erst nach vollständiger Testüberprüfung ermittelt werden.

Im eigentlichen Produktionsprozess, Je nach den unterschiedlichen Anforderungen an den Inhalt sollte der Standbeutel auf Dichtheit geprüft werden. Die einfachste und praktischste Methode besteht darin, den Beutel mit einer bestimmten Menge Luft zu füllen, Die Öffnung des Beutels heiß versiegeln, Legen Sie es in ein mit Wasser gefülltes Becken, und drücken Sie verschiedene Teile des Beutels mit Ihren Händen zusammen. Wenn keine Luftblasen austreten, Die Abdichtung und Luftdichtheit des Luftlecks im Beutel ist gut; ansonsten, Die Heißsiegeltemperatur und der Druck des undichten Teils sollten rechtzeitig angepasst werden.

Standbodenbeutel mit Flüssigkeiten sollten mit größerer Vorsicht behandelt werden. Mithilfe von Squeeze-and-Drop-Methoden lässt sich feststellen, ob sie undicht sind, wie zum Beispiel das Einfüllen einer bestimmten Menge Wasser in den Beutel, den Mund verschließen, und Prüfung gemäß der Druckprüfmethode von GB/T1005-1998. Die Falltestmethode kann sich auch auf die oben genannten Normen beziehen.

Ungleichmäßige Beutelform

Die Ebenheit ist einer der Indikatoren zur Messung der optischen Qualität von Verpackungsbeuteln. Neben materiellen Faktoren, Die Flachheit von Standbeuteln hängt auch von Faktoren wie der Heißsiegeltemperatur ab, Heißsiegeldruck, Heißsiegelzeit und Kühleffekt. Wenn die Heißsiegeltemperatur zu hoch oder der Heißsiegeldruck zu hoch ist oder die Heißsiegelzeit zu lang ist, Die Verbundfolie schrumpft und verformt sich.

Eine unzureichende Kühlung führt zu einer unzureichenden Formgebung nach dem Heißsiegeln, Es ist nicht möglich, innere Spannungen zu beseitigen und Falten im Beutel zu verursachen, Daher sollten die Prozessparameter angepasst werden, und das Kühlwasserzirkulationssystem sollte ordnungsgemäß funktionieren.

Schlechte Symmetrie

Symmetrie beeinflusst nicht nur die Optik des Standbodenbeutels, sondern beeinträchtigt auch die Dichtleistung. Die häufigste Asymmetrie des Standbeutels spiegelt sich häufig im unteren Materialteil wider. Aufgrund einer unsachgemäßen Kontrolle der Spannung des Untermaterials, Das runde Loch auf der Unterseite wird verformt oder es entstehen Falten aufgrund der Spannungsungleichheit mit dem Hauptmaterial, und die Heißsiegelfestigkeit wird verringert.

Wenn das runde Loch des Bodenmaterials verformt wird, Es ist notwendig, die Spannung der Entladung richtig zu reduzieren und die Wartezeit für die Korrektur während des Heißsiegelns zu verlängern, sodass der Schnittpunkt der vier Schichten am Boden des Beutels vollständig heißversiegelt werden kann.

Zusätzlich, Die Asymmetrie der Beutelform hängt auch mit Faktoren wie der fotoelektrischen Nachführung zusammen, Füttern, Cursor-Design, Gummirollenwaage, Schrittmotor- oder Servomotorsynchronisation. Dieses Problem sollte entsprechend dem spezifischen Betrieb verschiedener Produkte und verschiedener Beutelherstellungsgeräte gelöst werden.

III. Zwei Anwendungsbeispiele für Standbodenbeutel

Erfolgreicher Einsatz speziell geformter Standbodenbeutel

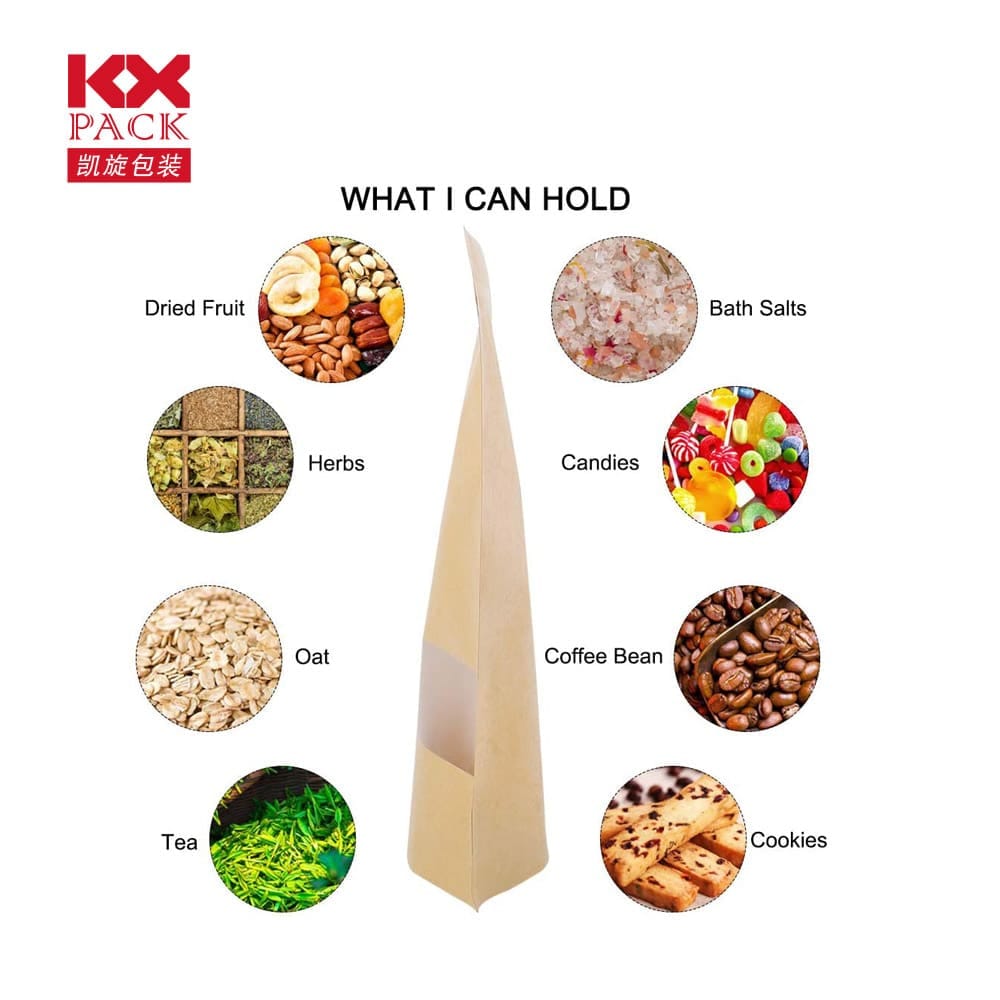

Die Funktion des Hinzufügens von Reißverschluss/Knochen besteht auch darin, das mehrfache Auspacken zu erleichtern. Der Unterschied besteht jedoch darin, dass die Wiederversiegelung über einen Reißverschluss/Knochenstreifen erfolgt, Daher ist diese Art von Design nicht zum Einkapseln von Flüssigkeiten geeignet, aber für die Verpackung einiger trockener Gegenstände, wie zum Beispiel: Kleidung, Süßigkeiten, Trockenfrüchte, Schokolade, Kekse, Gelee, Tee, usw.

Triumph Packaging ist Lieferant von Verpackungsbeuteln für bekannte Marken wie ISAAC, pams, Anker, ALTER, usw. Triumph Packaging kann tief in die Bedürfnisse der Kunden eintauchen, und angemessen spezifische Lösungen für Produktverpackungs-Upgrades entwerfen, damit Unternehmen Produkte wirklich bequemer und sicherer nutzen können , Kosten senken, Effizienz verbessern, Verbesserung der Produktästhetik, und umweltfreundlichere Bedürfnisse. Wenn das endgültige Unterstützungspaket dem Kunden vorgelegt wird, Auch der Kunde ist sehr zufrieden.

Erfolgreiche Anwendung des Standbodenbeutels mit Ausguss

Mittlerweile verbessert sich der Lebensstandard der Menschen ständig, und immer mehr Menschen sind es gewohnt, mit Waschmittel statt mit Waschpulver zu waschen. Denn das Waschmittel ist praktisch und schnell, Es ist keine wiederholte Reinigung erforderlich, Zeitersparnis, Arbeit und Wasser. Zu den Verpackungen für Waschflüssigkeiten gehören hauptsächlich Beutel und Dosen, und die Verpackung von Wäscheflüssigkeiten in Beuteln stellt höhere Anforderungen als gewöhnliche flexible Verpackungen.

Die Anforderungen an die Beutelfestigkeit, Fähigkeit, Flüssigkeitskorrosion und -durchdringung sowie schweren Gegenständen standzuhalten, Fallfestigkeit und Kratzfestigkeit, Transportsicherheit und Regaleffekte sind strenger.

Der Verpackungsbeutel für Waschmittel ist eine Verbundstruktur mit Farbdruck, Die am häufigsten verwendete Größe ist 2 kg, und es gibt zwei gemeinsame Strukturen wie folgt:

PET12/PA15/PE120

PET12/PA15/FOIL5/PE100

Für die Filmmaterialauswahl der oben genannten Verbundstruktur, Die Spezifikationen und die Leistung von doppelt gezogenem Polyester-PET und doppelt gezogenem Nylon-PA sind alle standardisiert.

Polyethylen PE ist der Schlüssel zur Qualität von Waschmittelverpackungsbeuteln.

Bei den meisten verpackten Waschmitteln handelt es sich um Standbeutel, und ein verkapptes Niederdruck-Polyethylen (HDPE) Dem Standbeutel wird ein harter Mund hinzugefügt, um einen Verpackungsbeutel mit Saugdüse zu bilden.

Zusätzlich zu den Vorteilen des einfachen Öffnens und mehrfachen Verschließens in Flaschen, Es hat auch den Vorteil, dass weniger Verpackungsmaterial verbraucht wird, hohes Druck- und Verpackungsniveau, Lagerung von Verpackungsmaterialien, niedrige Transportkosten, und kleine Menge Müllentsorgung. Es ist als umweltfreundliche Verpackung bekannt. .

Laut Statistik, im Vergleich zur gleichen Kapazität, Der Verbrauch an Rohstoffen in Säcken kann um mehr als reduziert werden 30%, Die Kosten für Lagerung und Transport von Verpackungsmaterialien können um mehr als gesenkt werden 60%, und auch die Menge der Müllentsorgung kann um mehr als reduziert werden 5 mal.

Für detailliertere Typen oder Fragen zu Standbodenbeuteln, bitte beziehen Sie sich auf: Standbeutel – China-Verpackungsbeutel & Film-OEM-Fabrik (kxpack.com)

Wir bieten qualitativ hochwertige Produkte, sind aber nicht darauf beschränkt, wettbewerbsfähige Preise, exzellenter Service, usw.