Bao bì thực phẩm phim tổng hợp khác bước nhảy vọt

Bao bì thực phẩm phim tổng hợp khác bước nhảy vọt

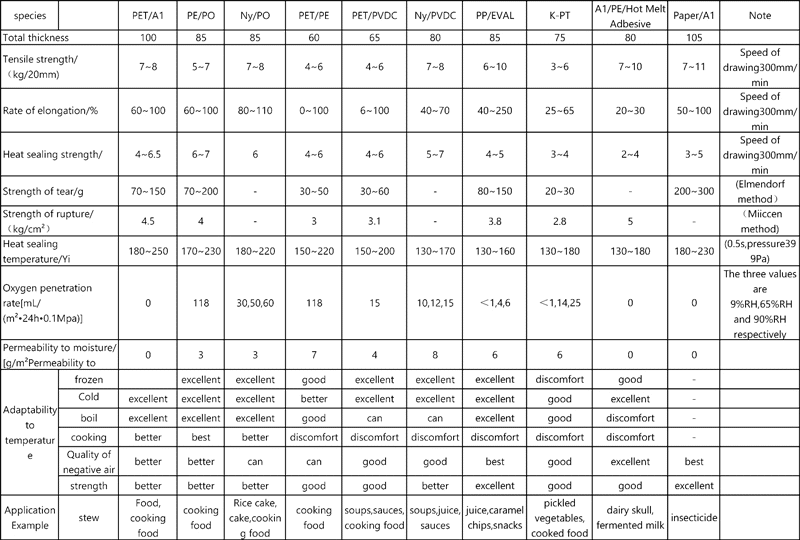

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, có thể được sử dụng trong một phạm vi nhất định, Nhưng một vật liệu duy nhất không thể có tất cả các thuộc tính của vật liệu đóng gói, không thể đáp ứng các yêu cầu chung của bao bì thực phẩm.

Vì vậy, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

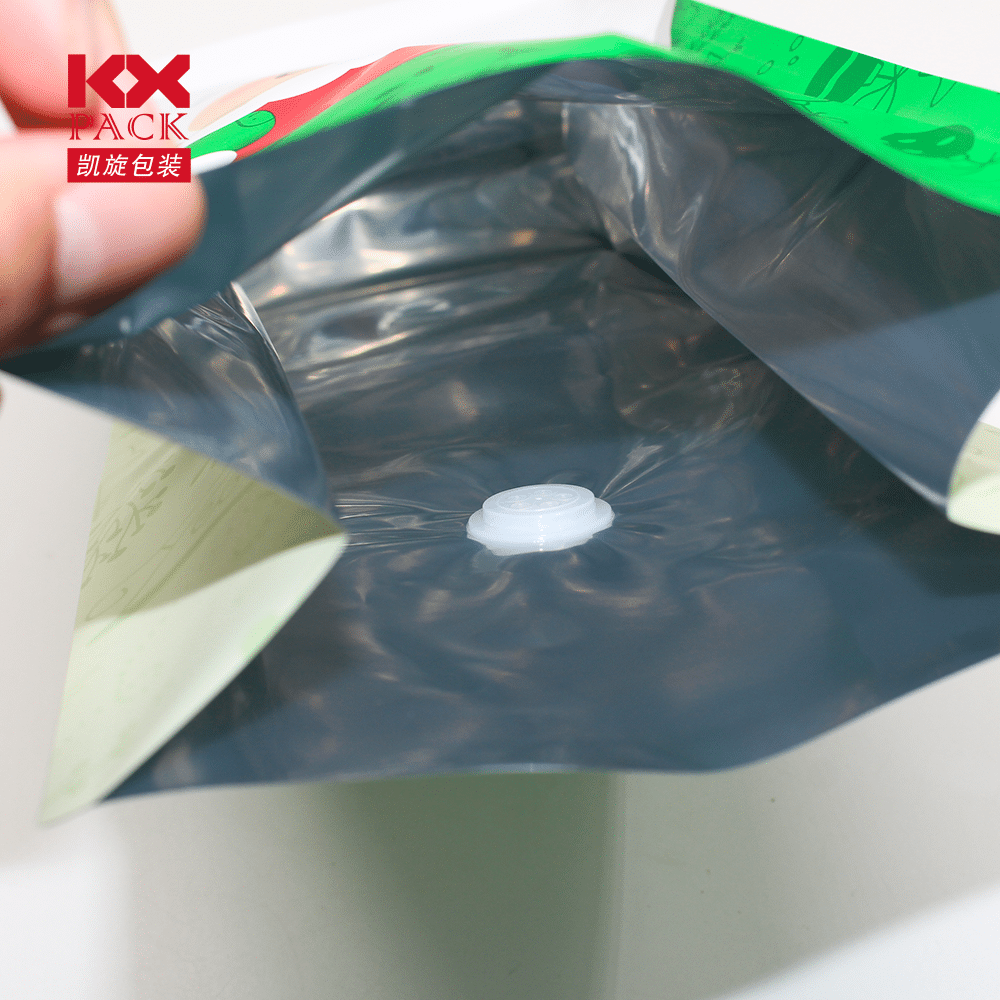

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: không độc hại, vô vị, oil resistance, kháng hóa chất

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, Eva, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, THÚ CƯNG, BOPP, máy tính, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Ví dụ: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Cách tùy chỉnh tái chế tốte composite film with us?

Công ty TNHH Bao bì Sán Đầu Kaixuan

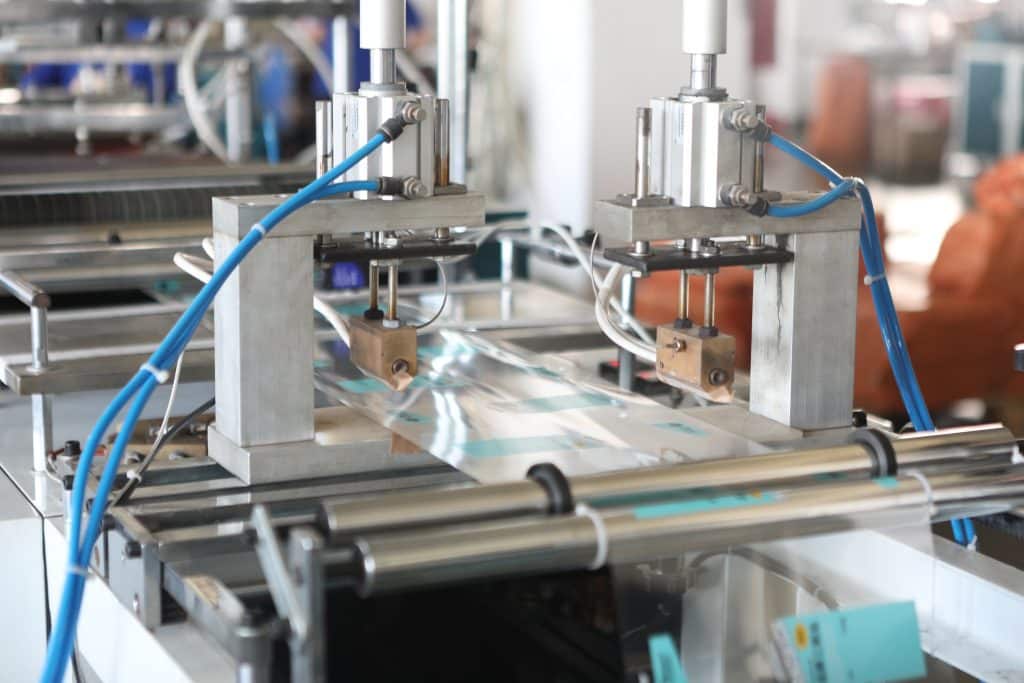

Nhà máy sản xuất trực tiếp tập trung vào bao bì hơn 20 năm,đặc biệt trong in màu,làm vỉ và túi. Tích hợp trong thiết kế,sản xuất và bán. Nhà máy Kaixuan có diện tích 20000㎡,được trang bị một 10000 xưởng không bụi,300m / phút 12 máy in ống đồng tốc độ cao màu,máy đóng vỉ tốc độ cao tự động công nghệ Đức,máy làm túi niêm phong tám mặt và thiết bị làm túi tiêu chuẩn cao khác.

Không có Benzen Không có mực Ketone. Trong khi đó, chúng tôi sử dụng không chứa benzen và không chứa ketone,mực và các vật liệu thân thiện với môi trường khác. Công suất hàng ngày có thể đạt tới 150 tấn,hoàn toàn đáp ứng nhu cầu của bạn trong An toàn,Hiệu quả và khỏe mạnh.

Chúng tôi chấp nhận đơn đặt hàng tùy chỉnh. Để cung cấp cho bạn một báo giá chính xác,Chúng tôi nên cần chi tiết của bạn như dưới đây:

- QTY

- Thiết kế màu in

- Vật liệu và độ dày

- Kích thước

Để biết thêm các loại chi tiết hoặc thắc mắc về màng bao bì thực phẩm, vui lòng tham khảo trước: https://kxpack.com/product-clegory/plastic-film/

Chúng tôi cung cấp nhưng không giới hạn ở các sản phẩm chất lượng cao, giá cả cạnh tranh, dịch vụ xuất sắc, vân vân.