فلمی پلاسٹک کی مہر کی استعداد اور جدت: لیب سے روزمرہ کی زندگی تک

پلاسٹک پر مہر لگانا

جدید دنیا میں, پلاسٹک پر مہر لگانا has quietly become an indispensable component across industries, لیبارٹری کے نمونے سے لے کر اپنے پسندیدہ نمکین تک ہر چیز کی حفاظت کرنا. یہ خصوصی مواد, ایئر ٹائٹ بنانے کے لئے ڈیزائن کیا گیا ہے, نمی مزاحم رکاوٹیں, استحکام کے تقاضوں اور تکنیکی ترقیوں کو پورا کرنے کے لئے تیزی سے تیار ہورہا ہے. آئیے اس کے متنوع ایپلی کیشنز کو دریافت کریں, مارکیٹ کے رجحانات, اور جدید بدعات.

1. Laboratory Applications: Protecting Scientific Integrity

In genomics, پروٹومکس, اور سیل کلچر, پلاسٹک پر مہر لگانا is a lifeline for preserving sample integrity. مثال کے طور پر:

- Microplate Sealing: Films like Parafilm®, a stretchable blend of hydrocarbon wax and polyolefin, are used to seal microplates and petri dishes. اس کی 200% elongation property allows it to conform to irregular shapes, preventing contamination and evaporation during long-term storage.

- PCR and Biotech Experiments: The film’s self-adhering nature ensures sterile conditions, critical for accurate DNA amplification and reagent stability.

مارکیٹ بصیرت: The laboratory segment is driven by the need for high-barrier materials that resist chemical degradation, a trend fueled by rising R&D investments in life sciences.

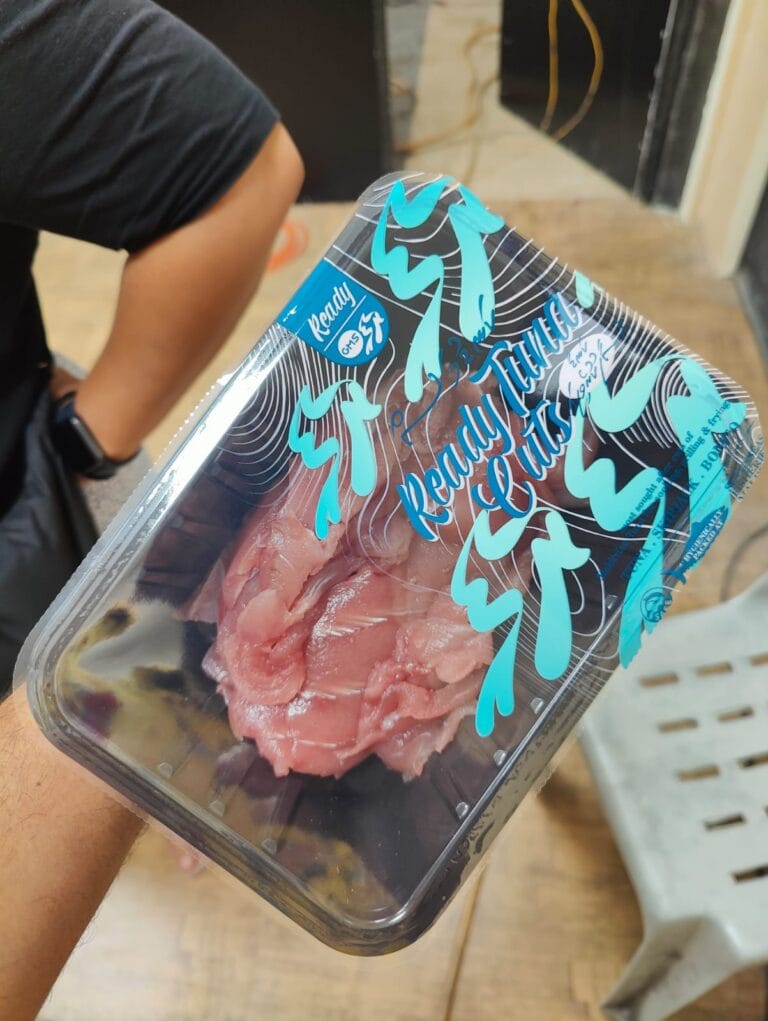

2. فوڈ پیکجنگ: Freshness Meets Sustainability

The food industry dominatesپلاسٹک پر مہر لگانا usage, with applications ranging from snack bags to fresh produce packaging:

- Snack Packaging: Heat-sealable PET films are used for potato chip bags, creating a tamper-proof seal that prevents moisture ingress and staleness. These films can be printed with vibrant designs without compromising seal quality.

- تازہ پیداوار: ترمیم شدہ ماحول پیکیجنگ (نقشہ) films extend the shelf life of fruits and vegetables by regulating oxygen and carbon dioxide levels. مثال کے طور پر, LDPE films with ethylene-absorbing layers slow down ripening.

- Innovative Designs: دی “مہر n ’فلپ ™” technology relocates the lidding film to the bottom of containers, reducing plastic use by 30% while enhancing product visibility on shelves.

مارکیٹ میں نمو: The global shrink plastic film market for beverage multipacks is projected to reachUSD 3.0 ارب کے ذریعہ 2025, driven by demand for processed beverages and eco-friendly alternatives.

3. دواسازی: Ensuring Potency and Safety

Pharmaceutical packaging relies onپلاسٹک پر مہر لگانا to protect drugs from moisture, روشنی, اور آلودگی:

- چھالا پیک: Aluminum-laminated PET films are used for tablets and capsules, combining puncture resistance with child-resistant features.

- Cold Seal Films: These are gaining traction for temperature-sensitive medications, as they eliminate heat exposure during sealing, preserving drug efficacy.

Key Players: Tier 1 manufacturers likeBemis Company اورAmcor Plc dominate the market, focusing on high-barrier, recyclable materials to meet regulatory standards.

4. Industrial and E-Commerce: Durability Meets Efficiency

لاجسٹک میں, پلاسٹک پر مہر لگانا ensures products survive transportation intact:

- پیلیٹ ریپنگ: Stretch films with reinforced layers prevent cargo shifting, reducing damage rates by up to 40%.

- E-Commerce Packaging: Cold seal films are ideal for automated packaging lines, as they require no heat, speeding up fulfillment processes for online retailers.

Innovation Spotlight: IoT-enabled films with embedded sensors are being tested to track temperature and humidity in real time, critical for perishable goods.

5. مارکیٹ کے رجحانات: Sustainability and Smart Packaging

دیCold Seal Plastic Films Market is expected to grow fromUSD 4.1 ارب میں 2025 to USD 7.2 ارب کے ذریعہ 2035, at a5.8% سی اے جی آر. کلیدی ڈرائیوروں میں شامل ہیں:

- پائیداری: Brands are shifting to compostable films made from PLA (پولیٹک ایسڈ) یا نشاستے کے مرکب, پلاسٹک کے فضلہ کو کم کرنا.

- Advanced Barriers: Co-extruded films combining PET, ایووہ, and PE layers offer superior gas and moisture resistance, مصنوعات کی شیلف زندگی کو بڑھانا.

- آٹومیشن مطابقت: Films designed for high-speed sealing machines are in demand, with impulse sealing and ultrasonic welding gaining popularity.

نتیجہ: فلمی پلاسٹک کو سیل کرنے کا مستقبل

From protecting lab samples to revolutionizing food packaging, پلاسٹک پر مہر لگانا is a testament to material science’s ability to balance functionality and sustainability. As industries prioritize eco-friendly solutions and smart technologies, innovations like biodegradable films and IoT integration will redefine its role. Whether you’re a scientist, a food manufacturer, or a consumer, this unassuming material touches your life daily—and its future is brighter than ever.

عمل کیلیے آواز اٹھاؤ: Are you exploring sustainable packaging options? Share your thoughts in the comments below or tag us on social media with #SealingFilmInnovation!