Дослідження світу друкованої упаковки фільму: Інновації та додатки

Друкована упаковка рулонна плівка

In the dynamic landscape of packaging solutions, Друкована упаковка рулонна плівка (PPRF) виділяється як універсальний та інноваційний матеріал, який перетворив спосіб упаковки продуктів, представлений, і захищений. Оскільки галузі все частіше прагнуть стійких, ефективний, і візуально привабливі варіанти упаковки, PPRF став кращим вибором, offering a myriad of benefits across various sectors.

What is Printed Packaging Roll Film?

Друкована упаковка рулонна плівка is a specialized type of plastic film that is designed to be printed with graphics, логотипи, text, and other visual elements. It is typically manufactured from materials such as polyethylene (PE), поліестер (ПЕТ), or oriented polypropylene (Бопп), and can be customized in terms of thickness, ширина, and length to suit specific packaging needs. The film is then wound into rolls, making it easy to handle, зберігати, and use in automated packaging machines.

Key Features and Benefits

1. Customization and Branding

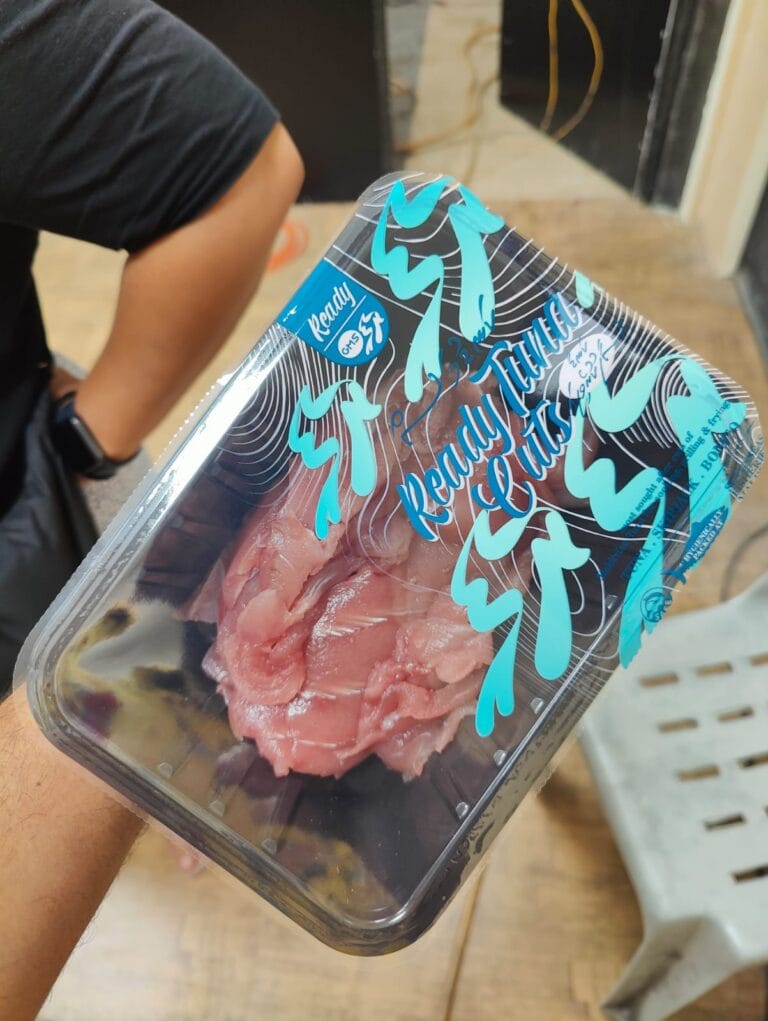

One of the most significant advantages of PPRF is its ability to be customized with high-quality prints. This allows businesses to showcase their brand identity, product information, and promotional messages directly on the packaging. Customized prints not only enhance the visual appeal of the product but also help in building brand recognition and loyalty among consumers. Наприклад, companies like Guangdong Danqing Printing Co., ТОВ. offer PPRF with up to 10 кольори, enabling intricate designs and vibrant visuals that make products stand out on the shelves.

2. Protective Properties

PPRF provides excellent protection against moisture, пил, and other environmental factors, ensuring that the packaged products remain fresh, безпечний, and intact. The film can be laminated with additional layers of materials such as aluminum foil or nylon to enhance its barrier properties, making it suitable for packaging food items, фармацевтичні препарати, and other sensitive products. Jiangxi Yixing Packaging Co., ТОВ. produces PPRF with features like high barrier, вологостійкий, and strong sealing, which are crucial for maintaining product quality and extending shelf life.

3. Cost-Effectiveness and Efficiency

Using PPRF for packaging can lead to significant cost savings compared to traditional packaging materials. The film is lightweight, reducing transportation costs, and can be processed at high speeds on packaging machines, increasing production efficiency. Додатково, PPRF is available in large rolls, minimizing waste and reducing the need for frequent material changes during production. Qingdao Zhongbang Packaging Co., ТОВ. emphasizes the cost-saving benefits of their PPRF, highlighting its excellent oxygen and moisture resistance, which helps in preserving product freshness and reducing spoilage.

4. Сталість і екологічність

Зі зростанням екологічних проблем, many Друкована упаковка рулонна плівка manufacturers are now focusing on producing eco-friendly PPRF. This involves using biodegradable materials, Чорнила на водній основі, and recyclable film structures. Some companies are also exploring the use of renewable energy sources in their production processes to further reduce their carbon footprint. The shift towards sustainable packaging solutions not only aligns with global environmental goals but also meets the increasing demand from consumers for eco-conscious products.

Applications of Printed Packaging Roll Film

PPRF finds extensive use across various industries, включаючи:

- Їжа та напої: PPRF is widely used for packaging snacks, кава, чай, цукерки, and other food items. Its moisture-proof and barrier properties help in preserving the freshness and flavor of the products.

- Фармацевтичні препарати: The pharmaceutical industry relies on PPRF for packaging medications, вітаміни, and supplements. The film’s ability to protect against moisture, світлий, and oxygen ensures the stability and efficacy of the drugs.

- Cosmetics and Personal Care: PPRF is used for packaging cosmetics, туалетні приналежності, and personal care products. Its customizable prints allow for attractive packaging designs that appeal to consumers.

- Industrial and Chemical Products: PPRF is also used for packaging industrial chemicals, adhesives, and other products. Its durability and protective properties make it suitable for handling and transporting these materials safely.

Innovations in Printed Packaging Roll Film

The packaging industry is constantly evolving, and PPRF is no exception. Recent innovations include:

- Розумна упаковка: Integrating smart technologies such as RFID tags, QR -коди, and time-temperature indicators into PPRF allows for better product traceability, inventory management, та залучення споживачів.

- Flexographic and Digital Printing: Advances in flexographic and digital printing technologies have enabled higher resolution prints, faster production speeds, and greater design flexibility on PPRF.

- Стійкі матеріали: Researchers are exploring the use of bio-based polymers, компостні плівки, and other sustainable materials in PPRF production to reduce its environmental impact.

Висновок

Printed Packaging Roll Film has revolutionized the packaging industry by offering a versatile, настроюється, and sustainable solution for businesses across various sectors. Its ability to combine high-quality prints with protective properties and cost-effectiveness makes it an ideal choice for modern packaging needs. As the industry continues to innovate and evolve, PPRF will undoubtedly play a pivotal role in shaping the future of packaging solutions. Whether it’s enhancing brand visibility, Забезпечення безпеки продукту, or promoting sustainability, PPRF has proven to be a game-changer in the packaging world.