Paketimi i ushqimit të filmit të përbërë një kërcim tjetër

Paketimi i ushqimit të filmit të përbërë një kërcim tjetër

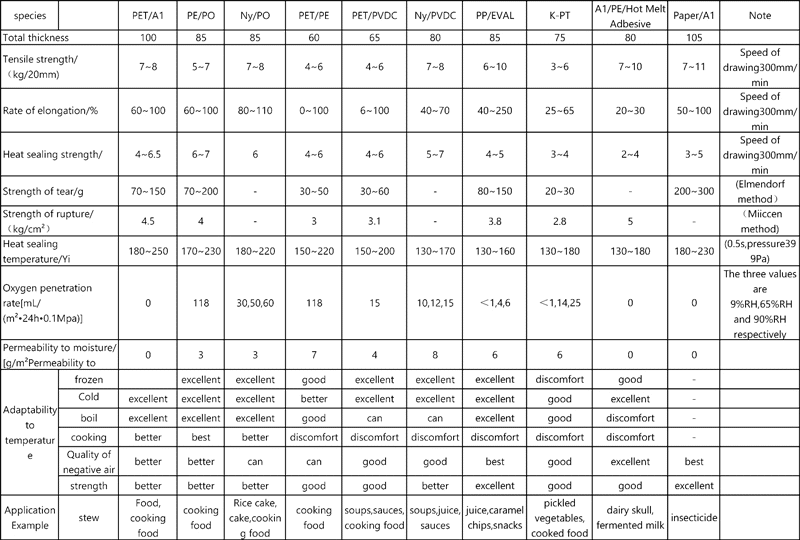

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, mund të përdoret në një gamë të caktuar, Por një material i vetëm nuk mund të ketë të gjitha vetitë e materialeve të paketimit, nuk mund të plotësojë kërkesat e përgjithshme të paketimit të ushqimit.

Prandaj, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

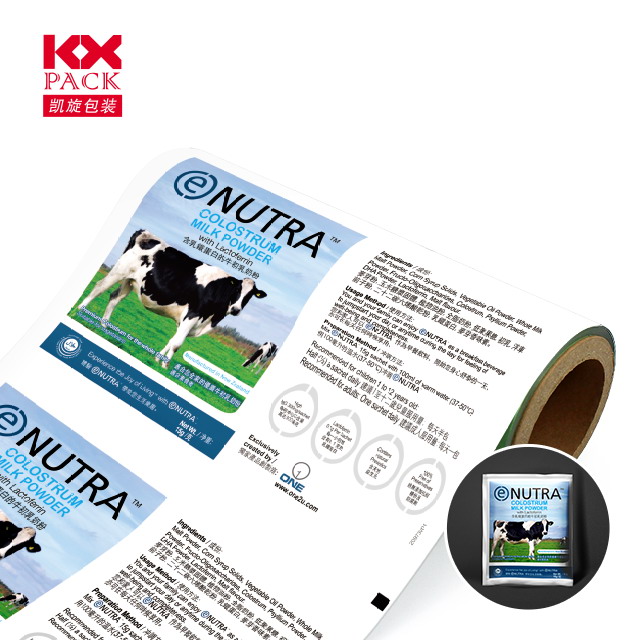

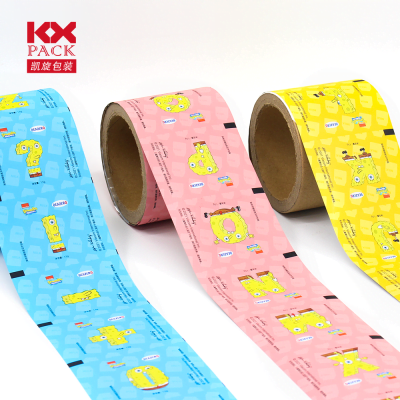

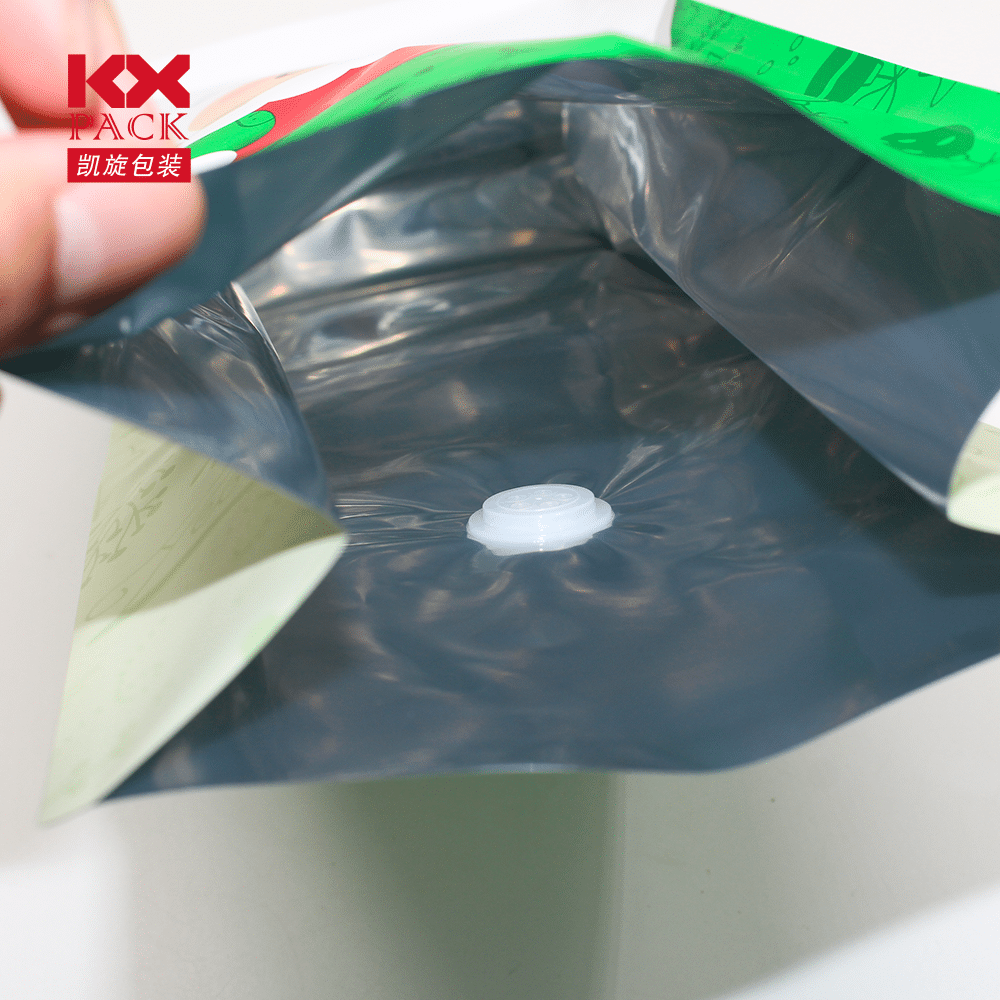

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

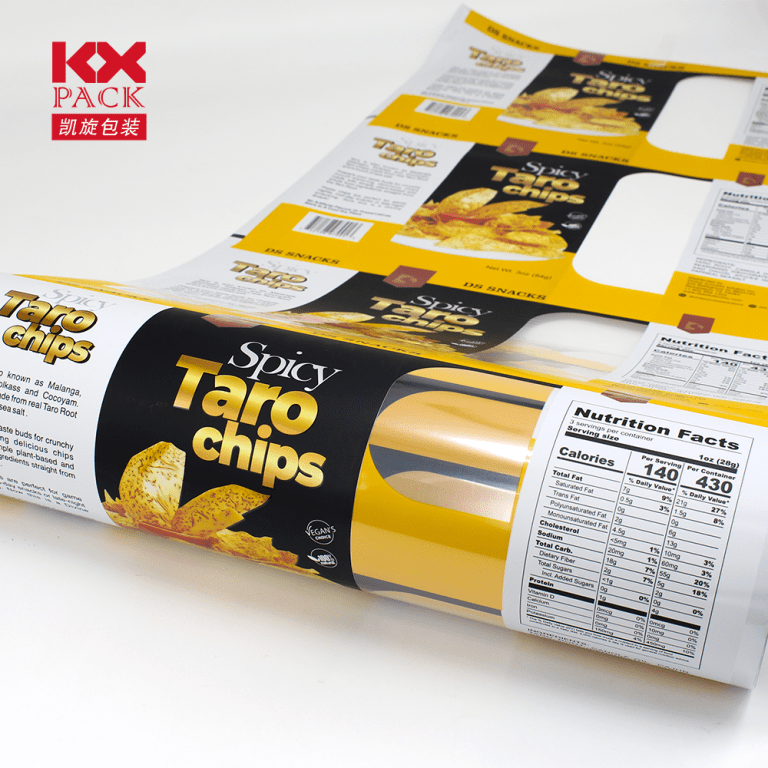

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: jo toksike, pa shije, oil resistance, rezistenca kimike

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, Eva, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, PET, Bopp, Pc, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Për shembull: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Si të personalizoni riciklimin e mirëE composite film with us?

Shantou Kaixuan Packaging Co, Ltd

Përqendrimi i drejtpërdrejtë i fabrikës në paketim 20 vjet,veçanërisht në shtypjen me ngjyra,bërjen e flluskave dhe qeseve.E integruar në dizajn,prodhim dhe shitje. Fabrika Kaixuan mbulon një sipërfaqe prej 20000㎡,pajisur me a 10000 punëtori e nivelit pa pluhur,300m/min 12 makinë printimi gravure me shpejtësi të lartë me ngjyra,Makinë automatike me blister me shpejtësi të lartë me teknologji gjermane,Makinë për prodhimin e qeseve me tetë anë dhe pajisje të tjera për prodhimin e qeseve me standarde të larta.

Nuk ka Benzen Pa Bojë Ketonike.Ndërkohë, ne përdorim pa benzen dhe pa keton,bojë dhe materiale të tjera miqësore me mjedisin. Kapaciteti ditor mund të arrijë 150 ton,plotësojnë absolutisht nevojat tuaja në Safe,Efikas dhe i shëndetshëm.

Ne pranojmë porosi të personalizuara. Në mënyrë që t'ju ofrojmë një kuotim të saktë,na duhen të dhënat tuaja si më poshtë:

- Sasia

- Printimi i dizajnit me ngjyra

- Materialet dhe trashësia

- Madhësia

Për lloje më të detajuara ose pyetje rreth filmave të paketimit të ushqimit, ju lutem referojuni: https://kxpack.com/product-category/plastic-film/

Ne ofrojmë, por nuk jemi të kufizuar në produkte me cilësi të lartë, çmimet konkurruese, shërbim i shkëlqyer, etj.