Fa'apipi'i Ata-Ta'u'aiga Mea'ai Seisi La'a

Fa'apipi'i Ata-Ta'u'aiga Mea'ai Seisi La'a

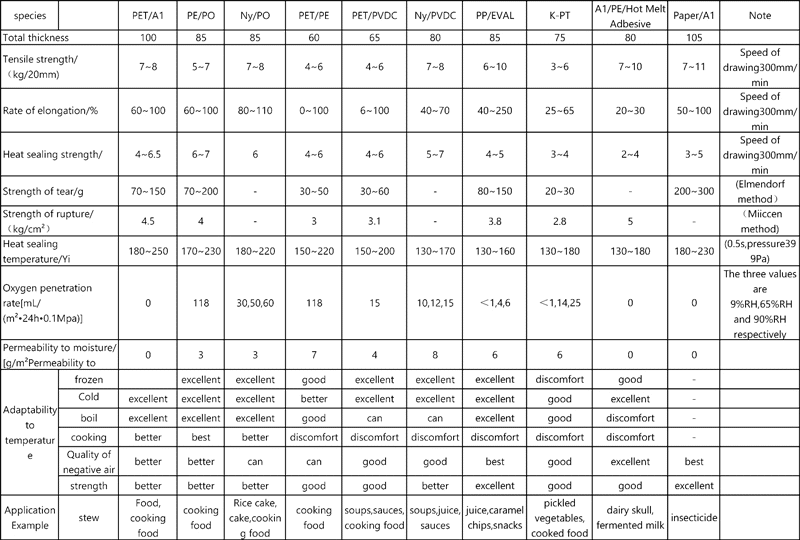

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, e mafai ona faʻaaogaina i se tulaga faʻapitoa, ae o se mea e tasi e le mafai ona maua uma meatotino o mea afifiina, e le mafai ona fa'amalieina mana'oga lautele o mea'ai afifi.

O lea la, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

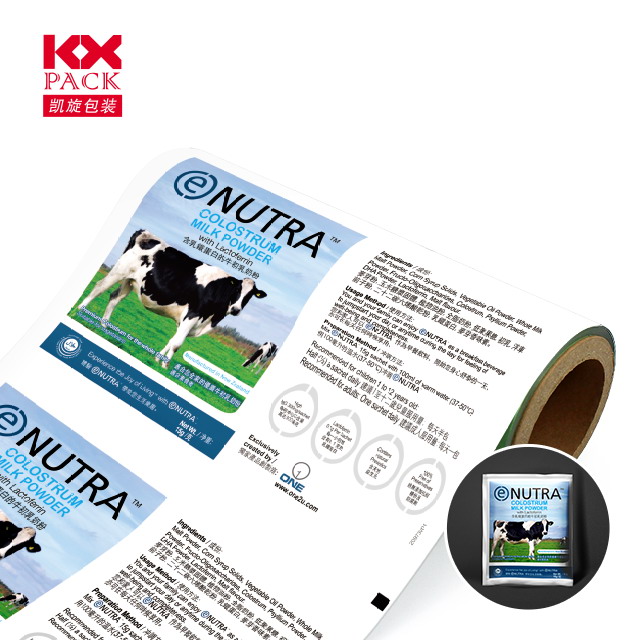

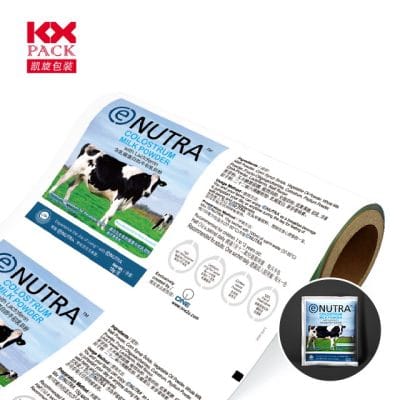

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

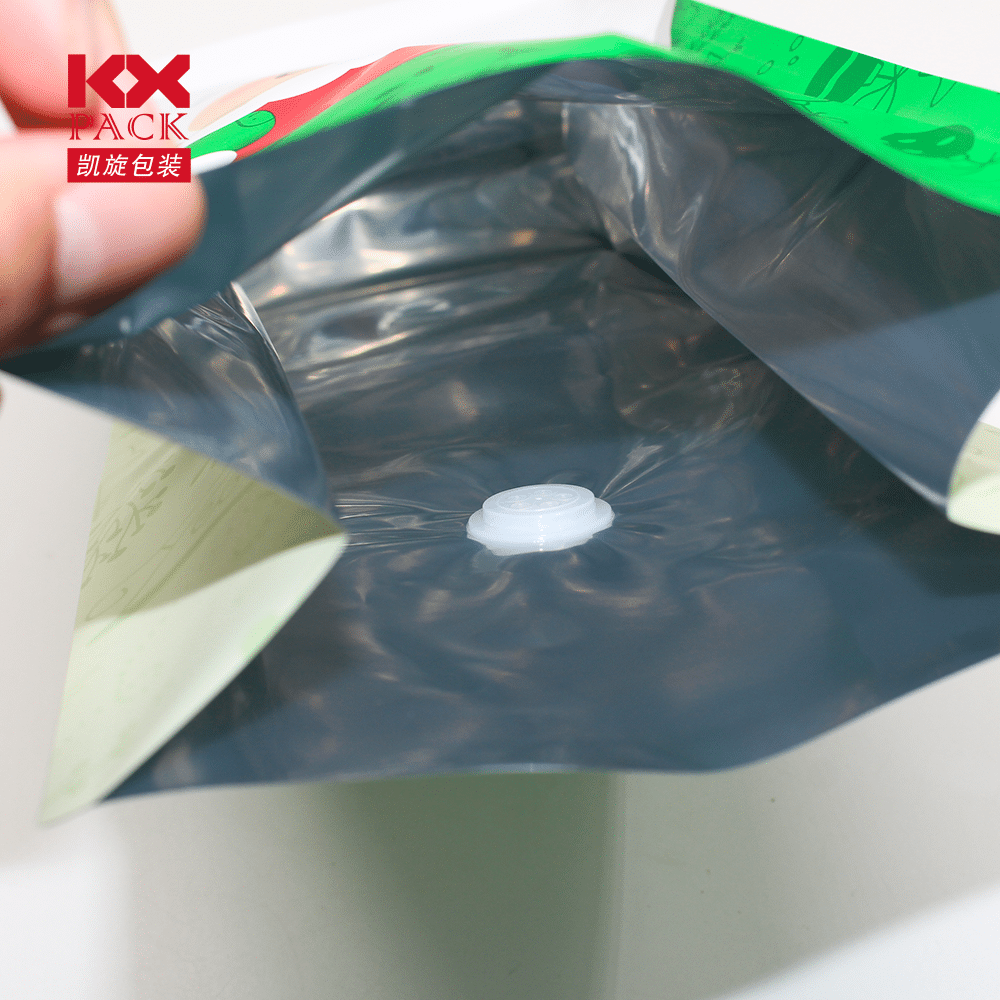

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, malosi maualuga, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: e le oona, leai se tofo, oil resistance, chemical resistance

Lelei, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, PET, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Faataitaiga: paper /PE/AL/PE, outer layer provides printing performance, feololo

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Faʻafefea ona faʻapitoa le faʻaaogaina o le leleiu Tusia ata ma matou?

Shantou Kaixuan Packaging Co.,Ltd

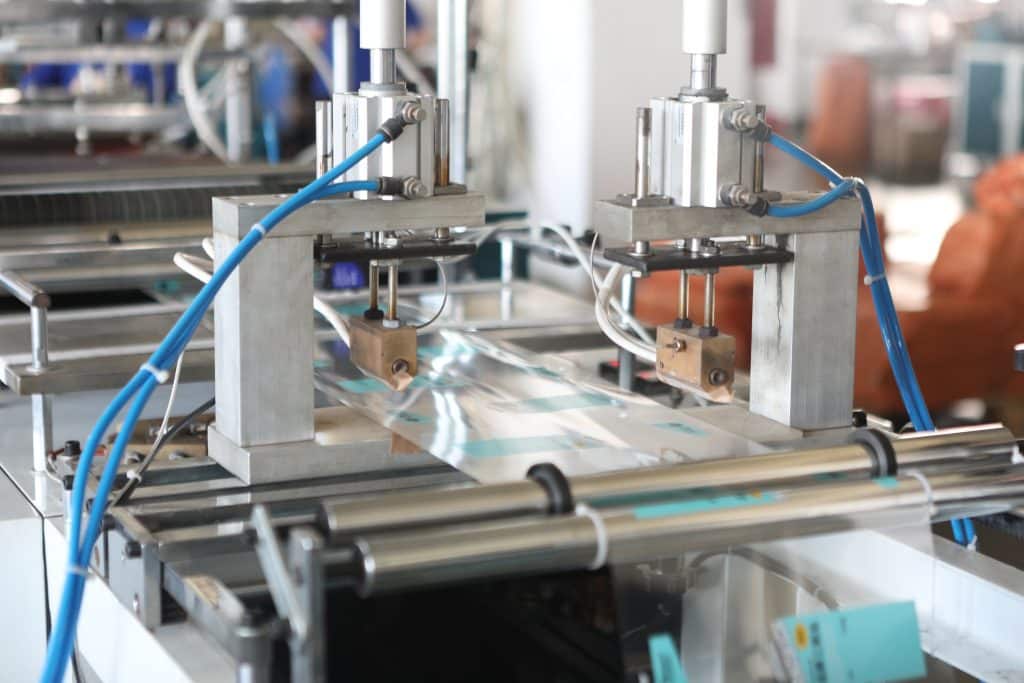

O lo'o taula'i atu le falegaosi mea'ai ile afifiina 20 tausaga,aemaise lava ile lolomi lanu,pa'u ma taga fai.Fa'atasi i le mamanu,gaosiga ma sale.Kaixuan falegaosimea e aofia ai se vaega o le 20000㎡,fa'apipi'iina i le a 10000 faleaoga e leai se pefu,300m/min 12 lanu maualuga-saosaoa gravure lomitusi masini,otometi maualuga-saosaoa blister masini ma tekinolosi Siamani,e valu itu fa'amau fa'amauga masini fai taga ma isi mea maualuga-fa'ata'ita'iga faia taga mea faigaluega.

Leai Benzene Leai Ketone Ink.I le taimi nei, matou te faʻaaogaina le benzene free ma le ketone free,vaitusi ma isi mea e fa'alelei le si'osi'omaga. E mafai ona o'o atu le gafatia i aso uma 150 tone,matua fa'amalieina ou mana'oga ile Safe,Lelei ma Soifua Maloloina.

Matou te talia faʻatonuga faʻapitoa. Ina ia ofoina atu ia te oe se upusii saʻo,e tatau ona matou manaʻomia au faʻamatalaga e pei ona i lalo:

- Qty

- Lomiga mamanu lanu

- Mea ma mafiafia

- Tele

Mo nisi fa'amatalaga auiliili po'o fesili e uiga i ata afifiina mea'ai, faamolemole tagai i: https://kxpack.com/product-category/plastic-film/

Matou te tuʻuina atu ae e le gata i oloa maualuga, tau faatauva, tautua lelei, ma isi.