Kompozitna folija-embalaža za živila Še en preskok

Kompozitna folija-embalaža za živila Še en preskok

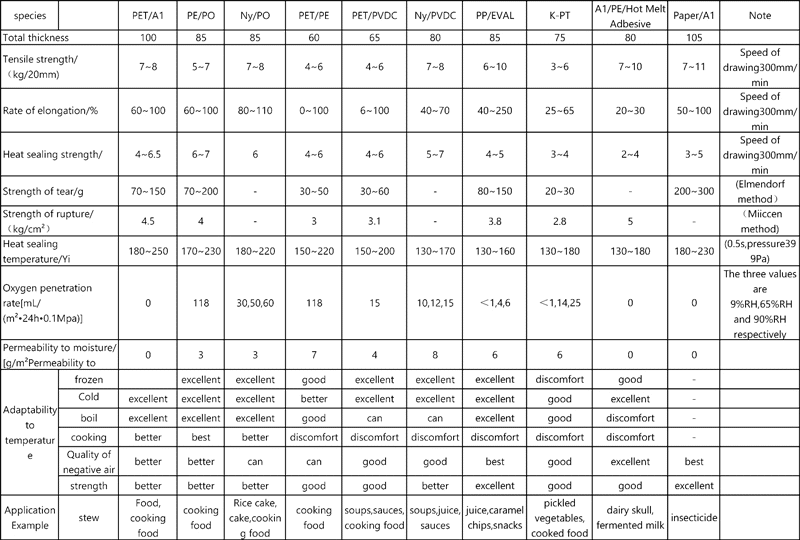

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, se lahko uporablja v določenem območju, Toda en sam material ne more imeti vseh lastnosti embalažnih materialov, ne morem izpolniti splošnih zahtev embalaže hrane.

Zato, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

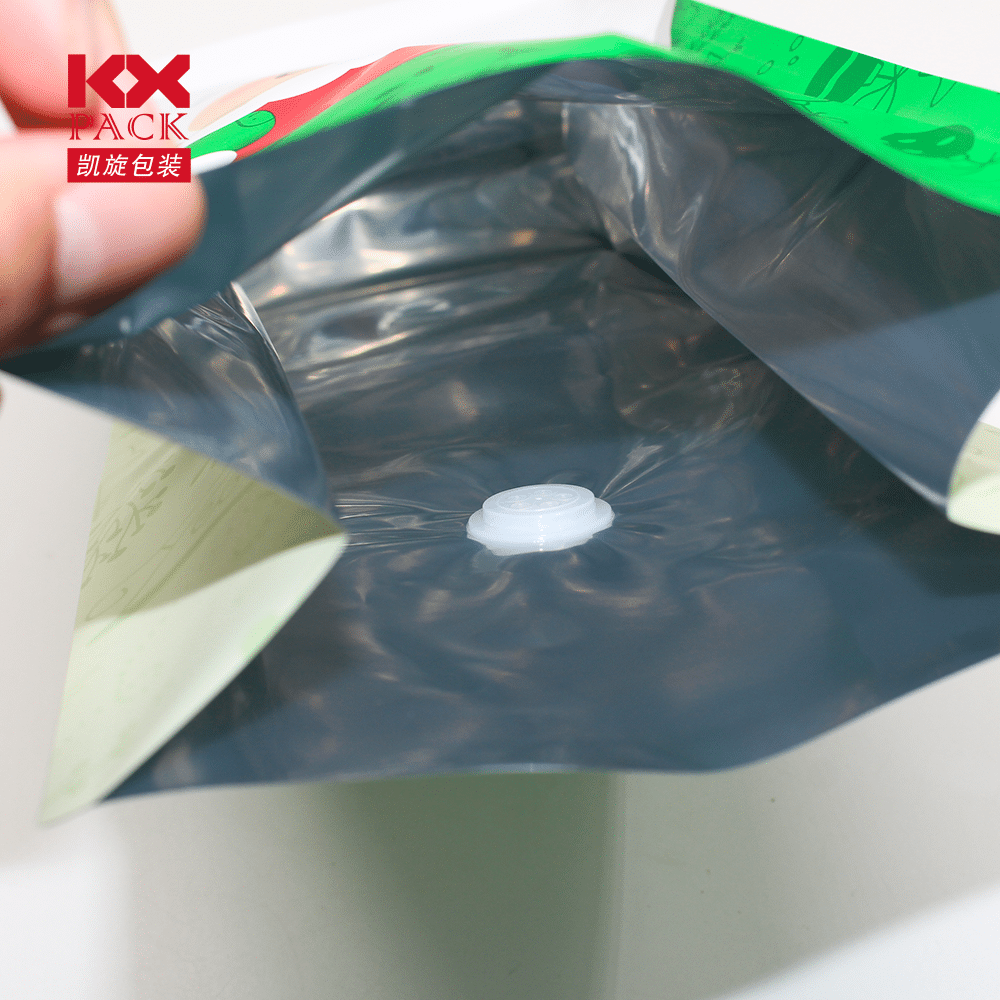

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: nestrupen, tasteless, oil resistance, kemična odpornost

Dobro, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, HIŠNE ŽIVALI, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Na primer: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

How to customize good recycle composite film with us?

Shantou Kaixuan Packaging Co., Ltd

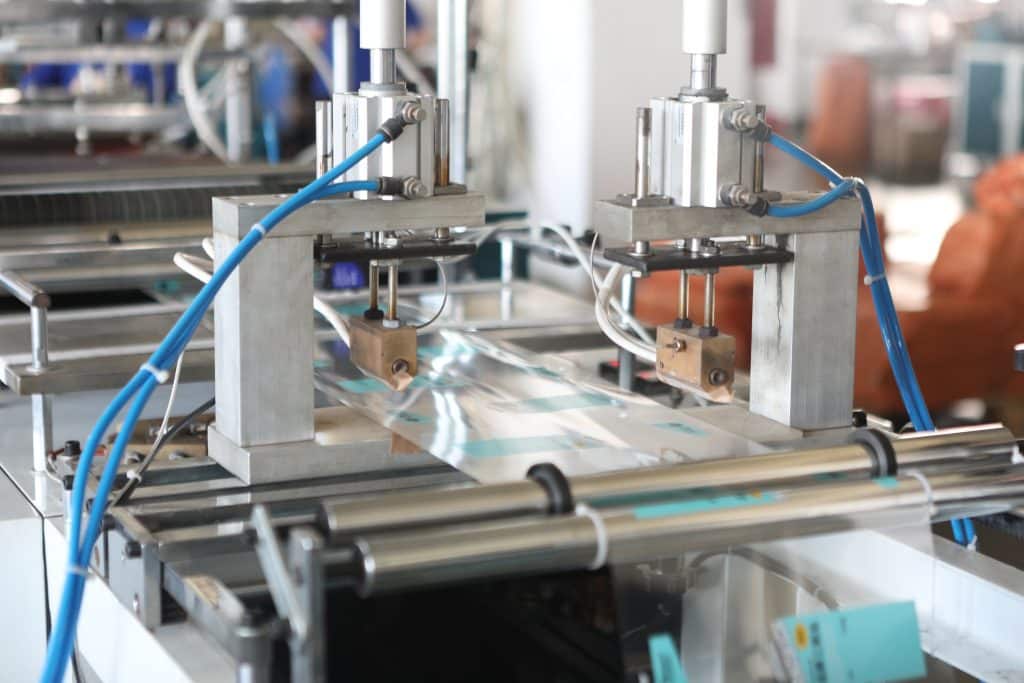

Neposredno osredotočanje proizvodnje na embalažo 20 leta,še posebej pri barvnem tisku,izdelava pretisnih omotov in vrečk. Vgrajeno v dizajn,proizvodnja in prodaja. Tovarna Kaixuan pokriva površino 20000㎡,opremljen z a 10000 ravni brezprašne delavnice,300m/min 12 barvni hitri stroj za globoki tisk,avtomatski hitri blister stroj z nemško tehnologijo,stroj za izdelavo vrečk z osmimi stranskimi tesnili in drugo visokostandardno opremo za izdelavo vrečk.

Brez benzena Brez ketonskega črnila. Medtem, uporabljamo brez benzena in brez ketonov,črnila in drugih okolju prijaznih materialov. Dnevna zmogljivost bi lahko dosegla 150 ton,popolnoma zadovoljiti vaše potrebe v Safe,Učinkovito in zdravo.

Sprejemamo prilagojena naročila. Da vam ponudimo pravilno ponudbo,potrebovali bi vaše podatke, kot je navedeno spodaj:

- Količina

- Barvno oblikovanje tiskanja

- Materiali in debelina

- Velikost

Za podrobnejše vrste ali vprašanja o folijah za pakiranje hrane, prosimo, glejte: https://kxpack.com/product-category/plastic-film/

Ponujamo visokokakovostne izdelke, vendar nismo omejeni nanje, konkurenčne cene, odlična storitev, itd.