Как выбрать правильную пленку по упаковке продуктов питания для ваших продуктов

Оглавление

я. Введение

1.1 The Critical Role of Food Packaging

Proper packaging is vital for preserving the quality, свежесть, и безопасность пищевых продуктов. Защищает предметы от внешних загрязнений., окисление, потеря влаги, и другие факторы, которые могут привести к порче. Упаковка также играет ключевую маркетинговую роль, привлекая потребителей и передавая информацию о продукте.. With such importance, selecting the right food packaging film is crucial for food manufacturers.

1.2 Пленки для упаковки пищевых продуктов – The Primary Barrier

Packaging films form the primary barrier between the food product and the external environment. They are typically the innermost layer that directly contacts the food item. An ideal packaging film maintains desired atmospheric conditions, prevents moisture migration, and blocks out light, odors, gases, and microorganisms that could degrade the product quality or pose health risks.

II. Types of Packaging Films

2.1 Plastic Films

Plastic films like polyethylene, полипропилен, and polyvinyl chloride have long been standard materials due to their excellent barrier properties, долговечность, и экономическая эффективность. Однако, environmental concerns have driven the exploration of alternative solutions.

2.2 Biobased and Biodegradable Options

To address sustainability issues, biobased and biodegradable films derived from renewable resources like polylactic acid (Плата), starch, целлюлоза, and chitosan have emerged. While offering eco-friendly advantages, these materials often face challenges in matching the performance of traditional plastic films.

2.3 Multilayer and Composite Films

By combining different polymers, multilayer and composite films can be engineered to achieve specific functional properties tailored to various food types. These advanced structures overcome individual material limitations to provide superior barrier qualities.

III. Key Considerations in Food Packaging Film Selection

3.1 Food Product Characteristics

The composition of the food product itself is a prime determinant of packaging needs. High moisture foods require excellent water vapor barriers, while fatty items demand superior oxygen barriers to prevent oxidation and rancidity.

3.2 Desired Shelf Life

Packaging must maintain product quality for the intended shelf life, which can range from days to years depending on the food type. Films with higher barrier properties are essential for extended shelf life requirements.

3.3 Storage and Distribution Conditions

Temperature, humidity, light exposure, and potential physical stresses during transportation and retail display can influence film choice. Harsher conditions necessitate more robust packaging solutions.

3.4 Соответствие нормативным требованиям

Food packaging films must comply with relevant food safety regulations and migration standards in the intended markets. Factors like chemical composition and risk of substance transfer to food are evaluated.

IV. Tailoring Films for Different Foods

4.1 Dry Foods

Закуски, cereals, выпечка, так далее. primarily require excellent moisture barriers to prevent caking, staling or loss of crispness. Materials like polypropylene offer good moisture protection.

4.2 Свежие продукты

Fruits and vegetables benefit from micro-perforated or highly gas permeable films that facilitate respiration and modify the atmosphere to delay ripening and senescence.

4.3 Meat and Seafood

High protein foods are susceptible to oxidation and bacterial spoilage. Excellent oxygen barriers like ethylene vinyl alcohol (ЭВОН) copolymers combined with effective sealants are essential.

4.4 Молочные продукты

Dairy items like milk, сыр, yogurt etc. require high moisture barrier films that are also odor/flavor barriers to avoid off-flavors or aroma absorption. Material purity is vital.

4.5 Baked Goods

In addition to moisture protection, baked products demand excellent aroma barriers to prevent flavor scalping or transfer of undesirable odors from packaging materials.

В. Emerging Packaging Trends

5.1 Sustainable and Eco-Friendly Solutions

With growing environmental consciousness, biobased, биоразлагаемый, перерабатываемый, and renewable packaging options with lower carbon footprints are increasingly preferred.

5.2 Активная и интеллектуальная упаковка

Advanced films incorporating additives for moisture regulation, antimicrobial properties, ethylene scavenging etc. along with integrated sensors for monitoring quality and safety are being developed.

5.3 Clean Labels and Transparency

Driven by clean label trends, consumers favor minimal processing and fewer artificial additives while demanding transparency about packaging materials and their safety.

VI. Заключение

6.1 Importance of Optimal Food Packaging Film Selection

Choosing the most suitable packaging film is critical to ensuring food quality, Расширение срока годности, сокращение отходов, and maintaining product integrity from processing to consumption.

6.2 A Holistic Approach to Protection

An effective packaging strategy requires a holistic consideration of the product’s unique characteristics, intended shelf life, storage conditions, regulatory landscape, as well as sustainability goals and emerging technological advancements. With the right films, food manufacturers can optimize protection, minimize losses, and meet evolving consumer expectations for freshness and food safety.

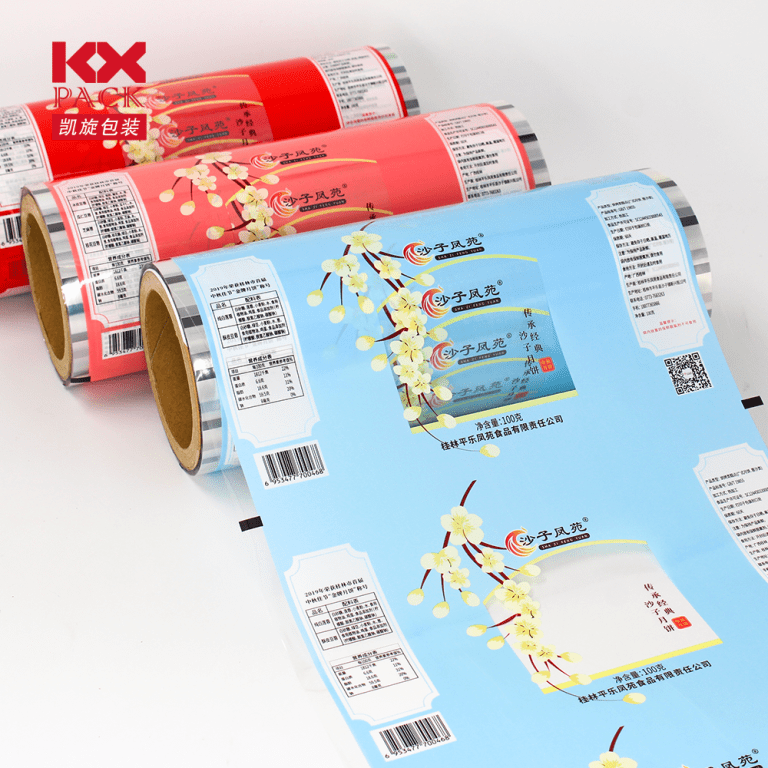

6.3 Шаньтоу Кайсюань упаковочная компания, ООО. – Your Trusted Partner

Шаньтоу Кайсюань упаковочная компания, ООО. is a direct manufacturer focused on packaging solutions for over 20 годы, with expertise in color printing, blistering, and bag making. As an integrated provider of design, производство, and sales, Kaixuan offers comprehensive packaging solutions.

With a 200,000m² facility housing a 100,000 ровная беспыльная мастерская, Kaixuan boasts advanced capabilities including 300m/min 12-color high-speed gravure printing machines, automatic high-speed blister machines with German technology, eight-side sealing bag making machines, and other high-standard equipment.

Partnering with Kaixuan ensures access to innovative, high-quality packaging films tailored to your specific food product needs, backed by two decades of industry experience and cutting-edge manufacturing capabilities.