Ambalaj compus cu alimente pentru un alt salt

Ambalaj compus cu alimente pentru un alt salt

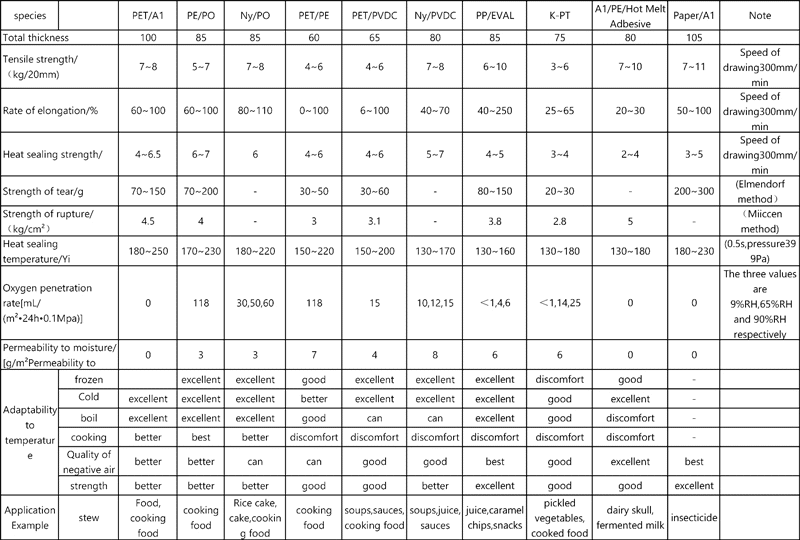

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, poate fi utilizat într -un anumit interval, Dar un singur material nu poate avea toate proprietățile materialelor de ambalare, nu poate îndeplini cerințele generale ale ambalajelor alimentare.

Prin urmare, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

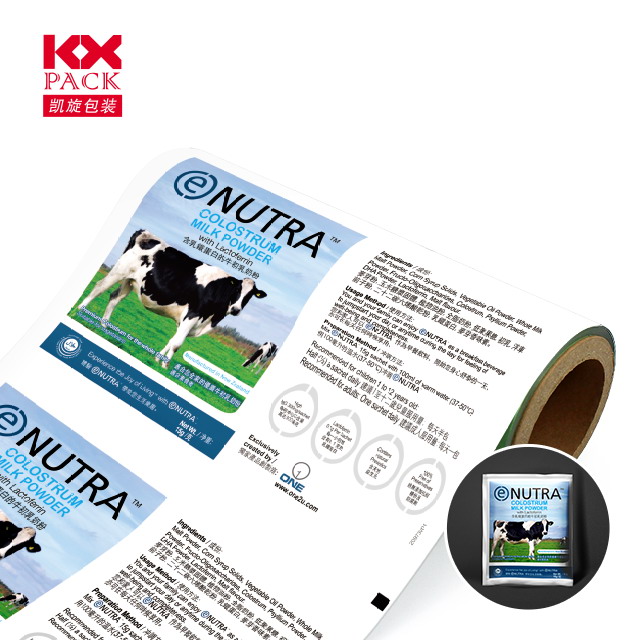

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

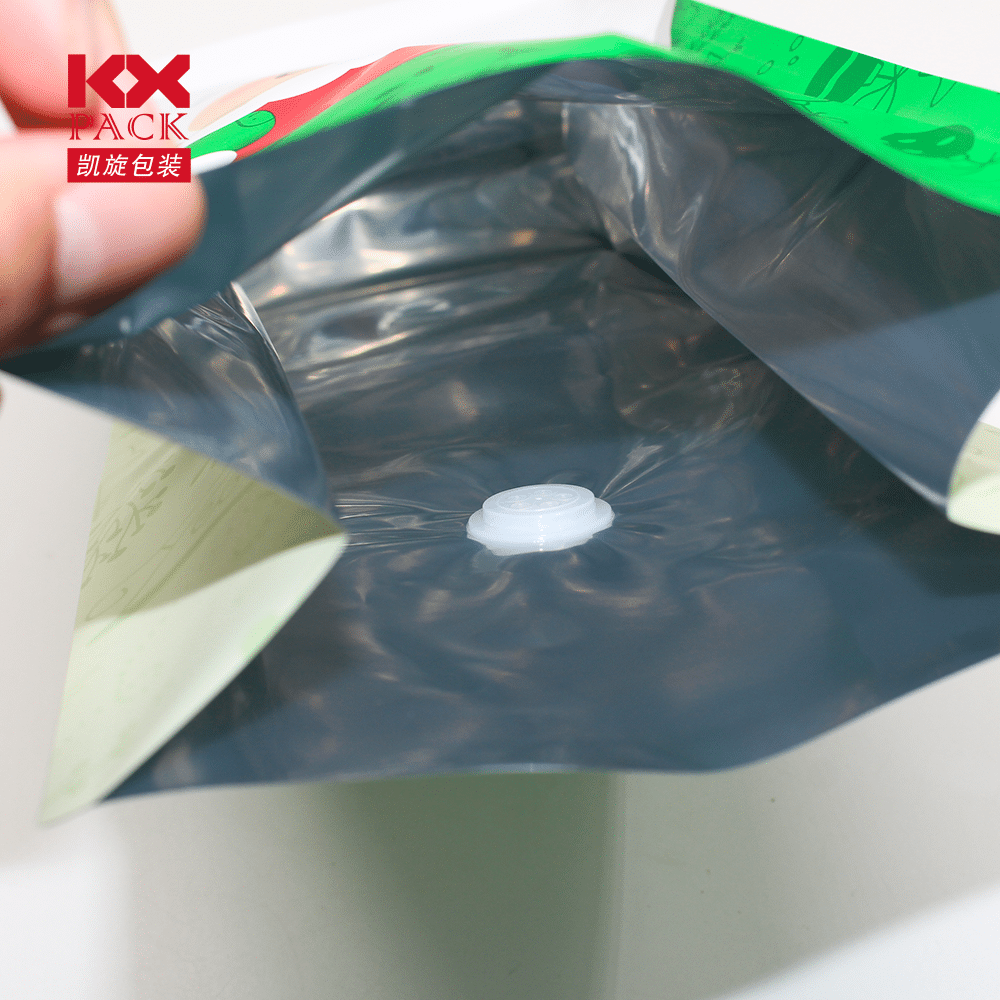

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: netoxice, lipsit de gust, oil resistance, rezistenta chimica

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, ANIMAL DE COMPANIE, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

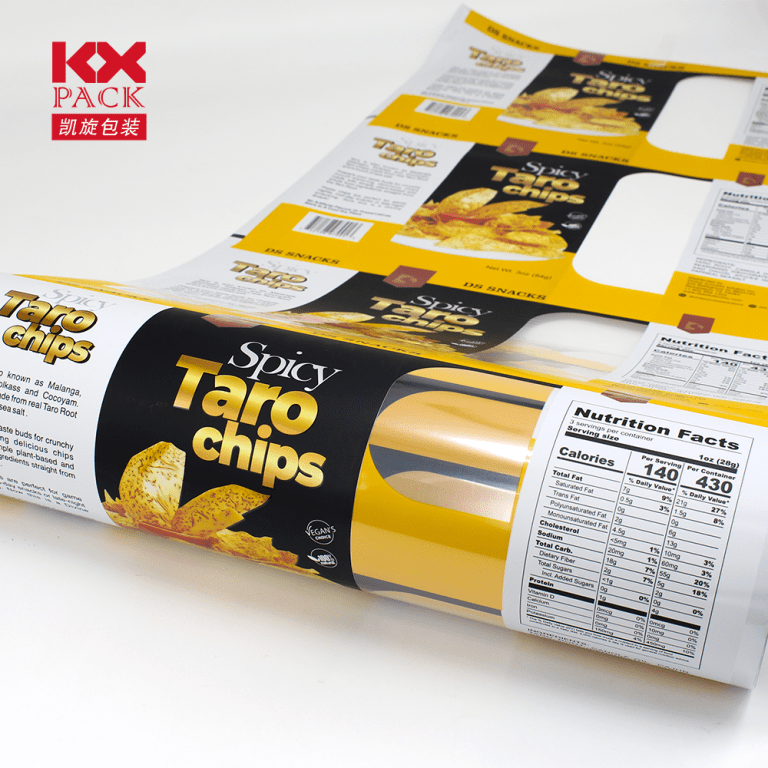

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

De exemplu: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Cum se personalizează Recicl bune film compus cu noi?

Shantou Kaixuan Packaging Co.,Ltd

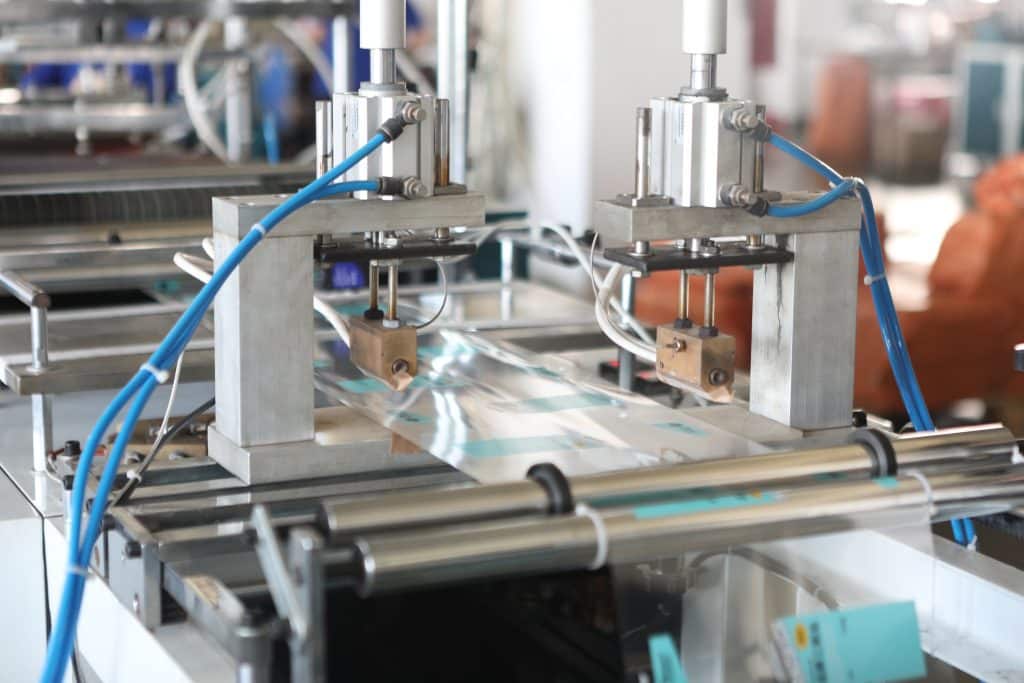

Concentrarea directă a fabricii pe ambalare 20 ani,în special în imprimarea color,confecționarea blisterelor și pungilor. Integrat în design,producție și vânzare. Fabrica Kaixuan acoperă o suprafață de 20000㎡,echipat cu a 10000 atelier nivel fără praf,300m/min 12 mașină de imprimat rotogravur color de mare viteză,mașină automată de blistere de mare viteză cu tehnologie germană,mașină de fabricare a pungilor de etanșare cu opt laterale și alte echipamente de fabricare a pungilor la standarde înalte.

Fara benzen Fara cerneala cetona.Intre timp, folosim fără benzen și fără cetone,cerneală și alte materiale ecologice. Capacitatea zilnică ar putea atinge 150 tone,satisface absolut nevoile dumneavoastră în Safe,Eficient și sănătos.

Acceptăm comenzi personalizate. Pentru a vă oferi o cotație corectă,ar trebui să avem nevoie de detaliile dvs. ca mai jos:

- Cant

- Imprimare design color

- Materiale și grosime

- mărimea

Pentru tipuri sau întrebări mai detaliate despre foliile de ambalare a alimentelor, va rog, referiti-va la: https://kxpack.com/product-category/plastic-film/

Oferim, dar nu ne limităm la produse de înaltă calitate, prețuri competitive, serviciu excelent, etc.