A evolução e aplicações do filme de laminação: Uma visão geral abrangente

Filme de laminação

No reino das embalagens, eletrônica, e fabricação industrial, filme de laminação permanece como um material fundamental, oferecendo durabilidade, proteção, e funcionalidade aprimorada. Este material versátil, composto por múltiplas camadas unidas por meio de processos especializados, revolucionou indústrias que vão desde embalagens de alimentos até eletrônicos avançados. Vamos mergulhar no mundo do filme de laminação, explorando seus tipos, Aplicações, e tendências futuras.

O que é filme de laminação?

Lamination film refers to a composite material created by bonding two or more layers of film—often polymers, metals, or paper—using heat, pressão, ou adesivos. The resulting structure combines the strengths of each layer, such as heat resistance, moisture barrier properties, or optical clarity. Por exemplo, a common configuration might include a polyester base layer coated with a heat-sealable adhesive, providing both strength and printability.

Key Types of Lamination Films

- BICHO DE ESTIMAÇÃO (Tereftalato de polietileno) Filmes:

- Conhecidos por sua transparência, resistência ao calor, and chemical stability, PET films are widely used in food packaging, rótulos, and electrical insulation.

- Variants like PET metalized films add a reflective layer for enhanced barrier properties, ideal for snack packaging or pharmaceutical blisters.

- Bopp (Polipropileno biaxialmente orientado) Filmes:

- BOPP films are prized for their moisture resistance, clareza, e custo-efetividade. They are commonly used in snack packaging, revistas, and laminated documents.

- Lustroso e acabamentos foscos cater to aesthetic and functional needs, such as anti-glare labels or premium packaging.

- Filmes de barreira:

- Esses filmes, often multi-layered, include aluminum or EVOH (Álcool Etileno Vinílico) layers to block oxygen, umidade, e luz. They are critical in extending the shelf life of perishable goods like coffee, carne, e produtos farmacêuticos.

- Filmes Especiais:

- Filmes antiestáticos prevent electrostatic discharge in electronics packaging.

- Security films incorporate holograms or UV-reactive inks for brand protection and anti-counterfeiting.

Industrial Applications

- Embalagens para alimentos e bebidas:

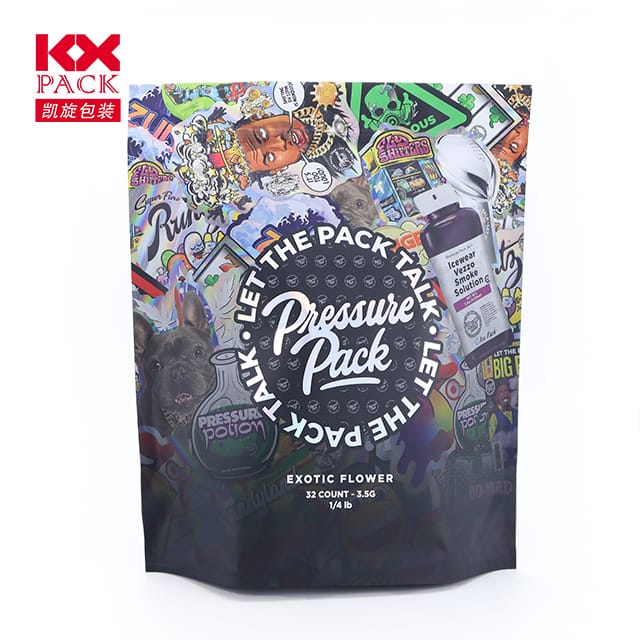

- Lamination films safeguard products from moisture, oxigênio, e dano físico. Por exemplo, um metalized PET film might be laminated with a sealant layer to create airtight pouches for coffee or nuts.

- Farmacêuticos:

- High-barrier films ensure the sterility and stability of medications. Blisters, por exemplo, often use PVC/PVDC/Aclar laminates to protect tablets from humidity and light.

- Eletrônica:

- In PCB (Printed Circuit Board) fabricação, dry film laminates act as photoresists, enabling precise circuit patterning. Adicionalmente, flexible printed circuits (FPCs) rely on ultra-thin lamination films for durability and bendability.

- Impressão e Gráficos:

- Laminated posters, menus, and ID cards benefit from enhanced durability and UV resistance. Por exemplo, um PET laminate might be applied to a printed substrate to protect against fading and scratches.

- Construction and Automotive:

- Films with high tensile strength and weather resistance are used in solar panels, automotive glazing, and architectural membranes.

Avanços tecnológicos

- Sustentabilidade: Manufacturers are developing biodegradável e reciclável lamination films to reduce environmental impact. Por exemplo, PLA-based (ácido polilático) filmes offer a compostable alternative to traditional petroleum-based plastics.

- Filmes Inteligentes: As tecnologias emergentes incluem thermochromic e photochromic laminates that change color with temperature or light exposure, abrindo portas para embalagens interativas.

- Nano-Layer Coatings: Ultra-thin layers of alumina or silica improve barrier properties without adding bulk, crucial for lightweight, high-performance packaging.

Market Trends and Challenges

- The global lamination film market is projected to grow steadily, driven by demand for sustainable packaging and advanced electronics. No entanto, Os desafios permanecem:

- Pressões de custos: Raw material price fluctuations and energy costs impact profitability.

- Conformidade Regulatória: Stringent food safety and environmental regulations necessitate continuous innovation.

- Competição de Alternativas: Rigid plastics and aluminum foil pose competition in certain applications.

Conclusão

Lamination film is more than just a protective layer—it’s a technological marvel that enhances product safety, estética, e funcionalidade. À medida que as indústrias evoluem, so too will lamination films, with advancements in sustainability, smart materials, and nano-engineering paving the way for the next generation of solutions. Whether in a snack bag, a smartphone screen, or a solar panel, lamination film continues to prove its worth as an indispensable material in modern manufacturing.

Stay tuned for more insights into the world of advanced materials and their role in shaping a sustainable future. 🌍✨