Spausdinta pakuotės ritinėlių plėvelė: Produktų pasakojimo ir tvarumo raida 2025

Spausdinta pakuotės ritinėlių plėvelė

In an era where consumer attention spans are shrinking and environmental consciousness is rising, Spausdinta pakuotės ritinėlių plėvelė has emerged as a game-changer for brands across industries. Nuo maisto ir kosmetikos iki farmacijos ir pramonės prekių, šis lanksčios pakuotės sprendimas iš naujo apibrėžia produktų pateikimą, apsaugota, ir suvokiamas. Panagrinėkime tendencijas, Naujovės, and strategic advantages driving its adoption in 2025.

1. Kodėl atspausdinta pakuotės ritinio plėvelė? The Core Benefits

a. Versatility in Design & Funkcionalumas

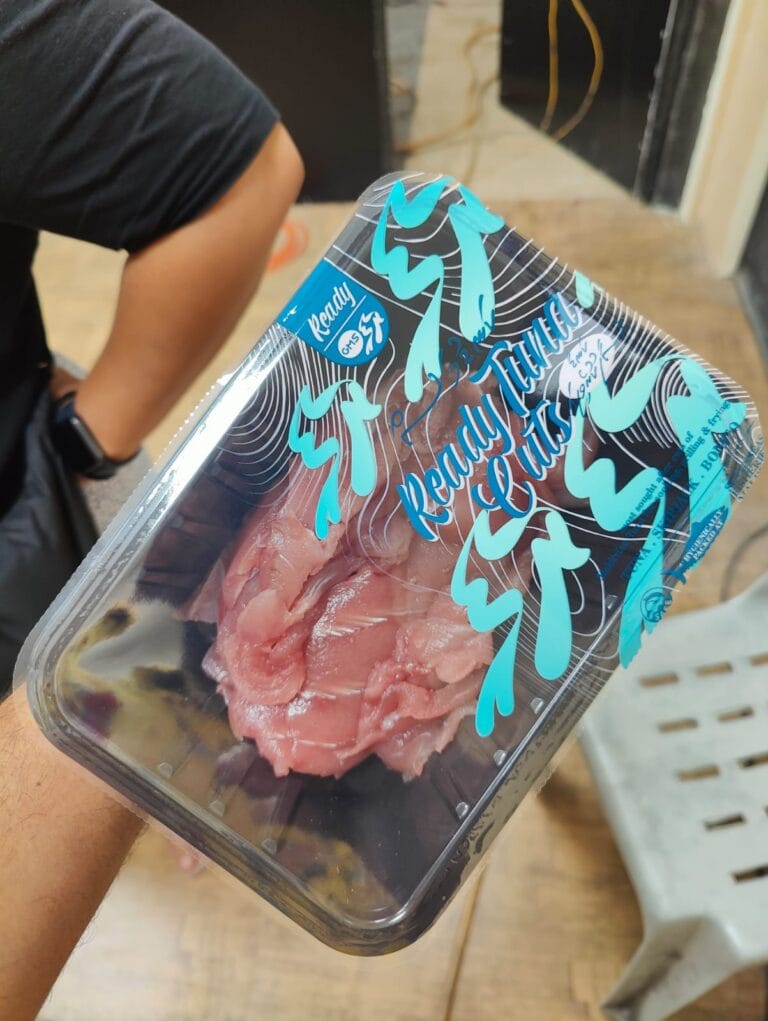

Spausdinta pakuotės ritinėlių plėvelė are engineered to adapt to diverse product shapes and sizes. Whether forming pouches for coffee beans, sealing fresh produce, or wrapping pharmaceuticals, these films combine durability with customization. Brands can leverage high-resolution graphics, Matinė apdaila, or even tactile textures to create shelf-ready packaging that stands out. Pavyzdžiui, CNG’s matte film roll, compliant with How2Recycle guidelines, demonstrates how aesthetics can align with sustainability.

b. Cost-Effective Flexibility

Low minimum print volumes and advanced form-fill-seal (FFS) machinery enable brands to launch seasonal campaigns, private labels, or limited editions without hefty upfront costs. A coffee brand, pavyzdžiui, can switch packaging designs quarterly by adjusting roll width and cut-off lengths, ensuring freshness in both product and branding.

c. Prailgintas galiojimo laikas & Saugumas

Technological advancements in multilayer films and active coatings (Pvz., antimicrobial, oxygen-scavenging) now allow printed roll films to double as protective barriers. CJ Biomaterials’ PHA-based coatings, pavyzdžiui, offer compostable solutions that prevent microbial growth, extending the shelf life of perishables while appealing to eco-conscious consumers.

2. 2025 Trends Shaping the Industry

a. Sustainability as a Non-Negotiable

The bioplastic segment is growing at a CAGR of 5%, driven by regulations and consumer demand. Brands are transitioning to films made from 30% perdirbta po vartojimo (PGR) plastic or compostable materials like PHA. Design Polymerics’ shift from white to black pails with PCR content exemplifies how even ancillary packaging components are evolving.

b. Išmanioji pakuotė & Interactivity

Embedded QR codes, NFC žymos, or temperature-sensitive inks are turning printed films into interactive storytelling tools. A skincare brand, pavyzdžiui, could use a scannable film to share ingredient sourcing stories or usage tutorials, deepening customer engagement.

c. Regional Market Dynamics

- Asia-Pacific: Dominates due to its vast consumer base and industrial growth. Brands here prioritize cost-efficient, high-volume roll films for snacks and beverages.

- Šiaurės Amerika: Leads in innovation, with brands investing in premium finishes (Pvz., holographic prints) and recyclable structures to meet stringent sustainability standards.

3. Key Considerations for Brands

a. Medžiagos pasirinkimas & Spektaklis

Choosing the right Spausdinta pakuotės ritinėlių plėvelė structure is critical. A multilayer film with a PET/PE/EVOH composition might be ideal for oxygen-sensitive products, while a monolithic PHA film suits compostable snack packaging. Partnering with suppliers who offer material testing and dieline templates ensures compatibility with FFS machines.

b. Printing Precision & Color Consistency

High-definition gravure or digital printing techniques now support up to 11-color designs, but brands must account for ink adhesion on recycled content. Sollex’s specialized blades, tailored for abrasive multilayer films, highlight the importance of selecting cutting tools that prevent defects during conversion.

c. Reguliavimo laikymasis

With global regulations on recyclability (Pvz., ES vienkartinių plastikų direktyva) and food safety (FDA/EFSA), brands must verify that their printed films meet standards for direct food contact and recyclability claims.

4. Ateitis: Beyond Packaging

Spausdinta pakuotės ritinėlių plėvelė are evolving into brand ambassadors. Imagine a film that changes color when a product expires or a pouch that releases a fragrance when opened. Innovations like these, combined with AI-driven design tools, will enable hyper-personalized packaging at scale.

Išvada

Į 2025, printed packaging roll film is no longer just a protective layer—it’s a strategic asset. Brands that harness its flexibility, tvarumas, and technological potential will not only reduce costs but also forge deeper connections with consumers. As the packaging films market grows at 5% CAGR, the question isn’t whether to adopt printed roll films, but how creatively you can leverage them to tell your brand’s story.

Ready to transform your packaging? Start by auditing your current materials, exploring bioplastic alternatives, and experimenting with interactive designs. The roll film revolution is here—and it’s printed in full color.

Šaltiniai: Industry reports, PennPac insights, ir 2025 market analyses.