複合フィルム-食品包装の更なる飛躍

複合フィルム-食品包装の更なる飛躍

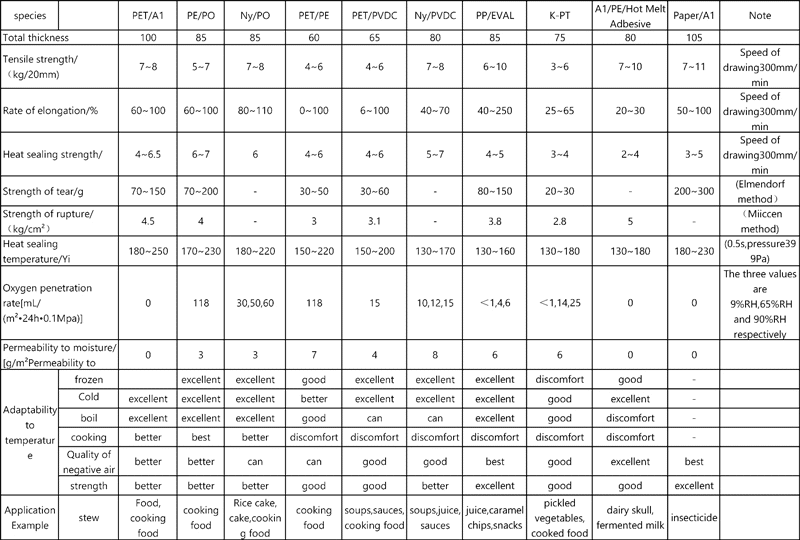

梱包材の種類も豊富です, しかし、パフォーマンスには大きな違いがあります.

優れた特性を数多く備えているにもかかわらず、, 一定の範囲内で使用できる, しかし、単一の材料が包装材料のすべての特性を持つことはできません。, 食品包装の全体的な要件を満たすことができない.

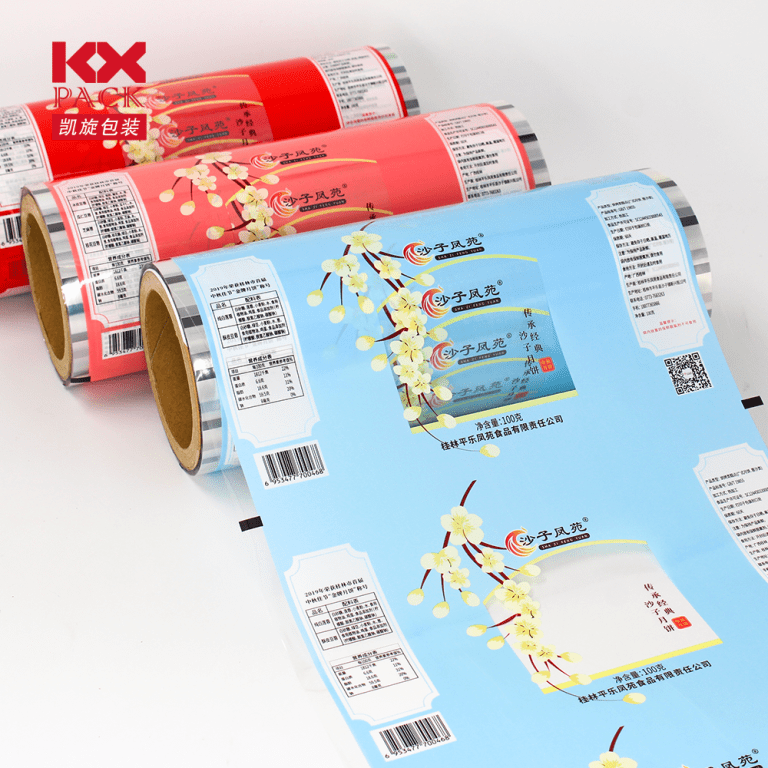

したがって, さまざまな使用目的に応じて, 異なる包装材料を組み合わせて、さまざまな総合的な包装性能を実現します。, このようにして複合包装材料が製造されます.

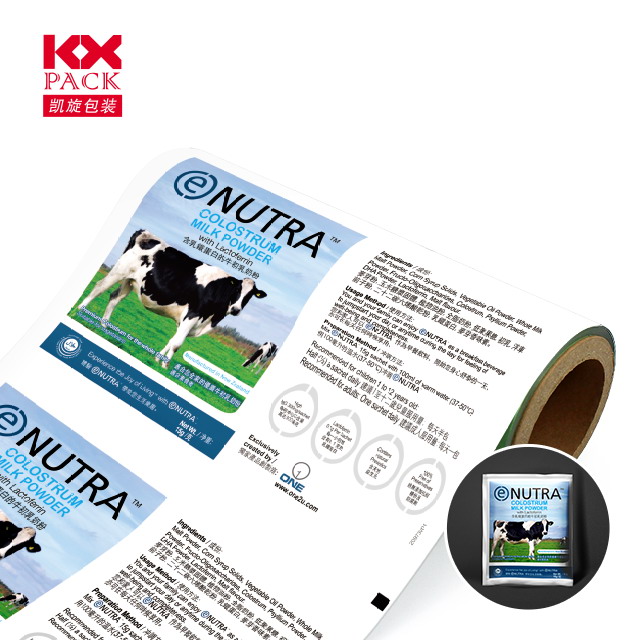

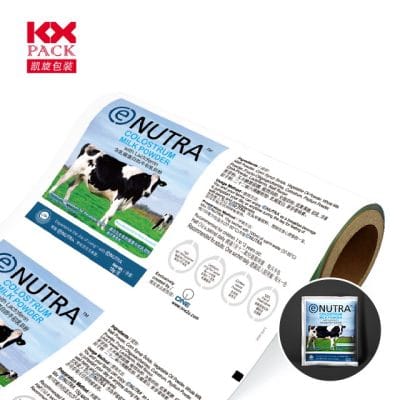

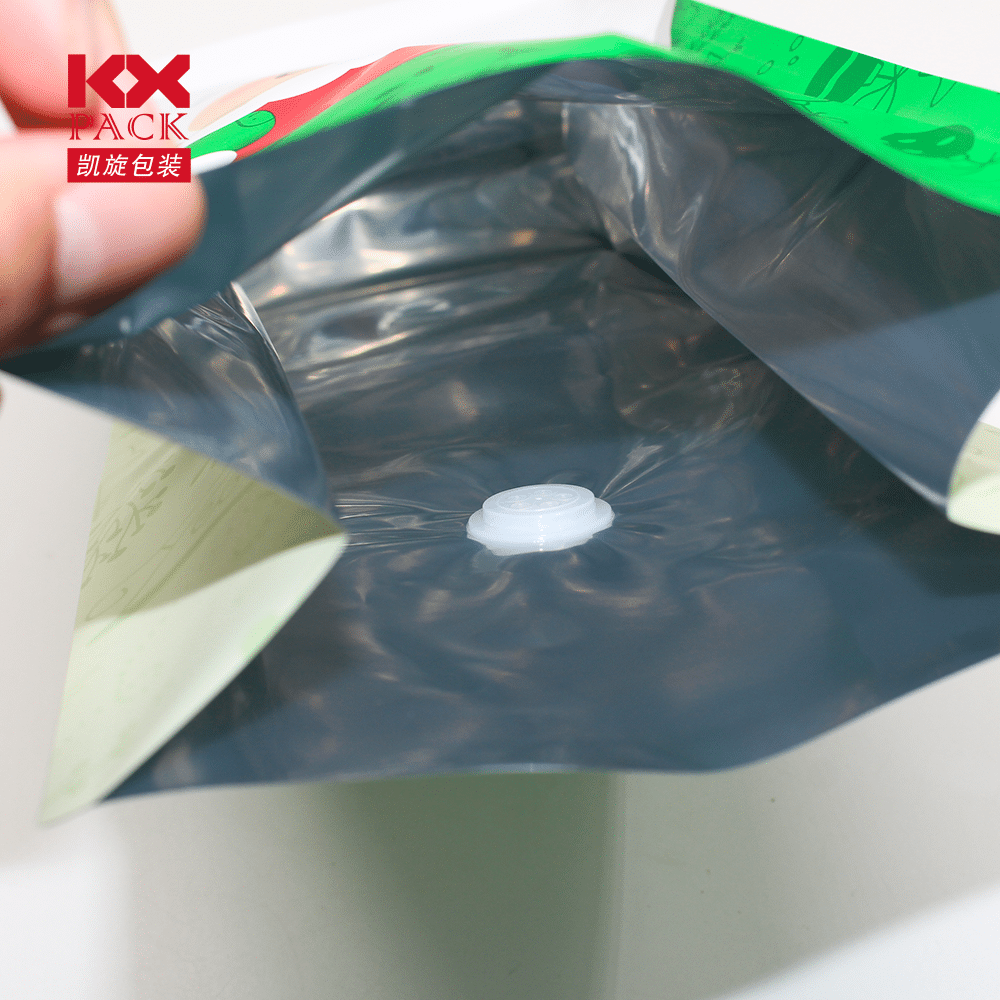

複合フィルム 包装材料とは、異なる種類の柔軟な材料を 2 層以上重ねたものを指します。, テクノロジーの特定の組み合わせによって.

“構造化された” 多層材料. 複合基板はプラスチックフィルムです, アルミホイルと紙.

複合包装フィルム, 食品包装材料の最も重要なカテゴリーとなっています, 食品包装の開発方向性です.

複合フィルムには単一フィルムとは比べものにならない2つの利点があります:

- 優れた総合的な包装性能.

複合フィルム, 複合材料を構成する単一フィルムの特性をすべて組み合わせたもの,

ハイバリア付き, 高強度, 良好なヒートシール, 高抵抗

温度と保圧作業の適応性.

- 良好な健康と安全のパフォーマンス.

印刷層を中央に配置することができます, 内容物が汚染されておらず、保護されている

印刷加飾層の役割を守る.

食品内装用複合フィルムの構造要件:

- 内層の要件: 無毒, 無味な, 耐油性, 耐薬品性

良い, ヒートシールまたは接着による. 一般的に使用される内層にはPEが使用されています,

CPP, エヴァ, イオン性ポリマーおよびその他の熱可塑性プラスチック. - 外部要件: 良好な光学特性, 良好な印刷適性, 耐摩耗性と耐熱性, 強度と剛性を備えた. 一般的に使用される外層はPAです, ペット, ボップ, パソコン, アルミホイルと紙.

- 中間層の要件: 高いバリアで (ヤン・シャン, アンチ

湿気と日陰), 中でもアルミ箔とPVDCが最もよく使われる製品です。

種の.

複合フィルムの表現:

左から右へ外層です, 中層および内層材料,

例えば: 紙/PE/AL/PE, 外層は印刷性能を提供します, 中くらい

中間のPE層が接着剤として機能します, 中間の AL はバリアと剛性を提供します

程度, 内側のPEがヒートシール性能を発揮.

良いリサイクルをカスタマイズする方法e 私たちと一緒に複合フィルム?

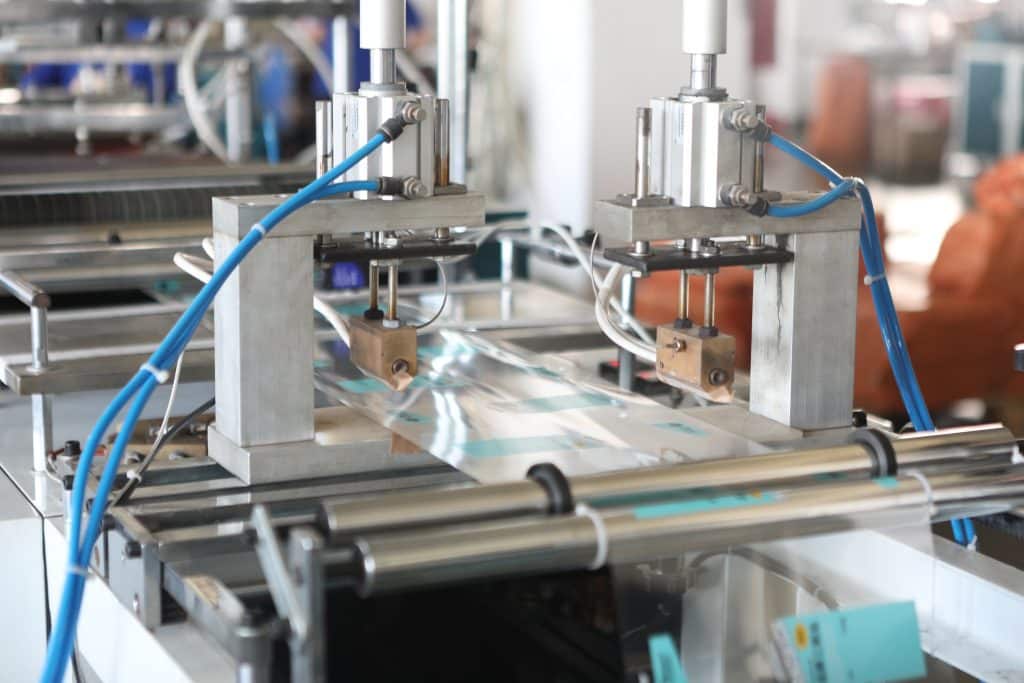

以上の包装に直接工場の焦点を当てる 20 年,特にカラー印刷で,ブリスターとバッグの製造。デザインに統合,生産と販売.Kaixuan工場は20000㎡の面積をカバーしています,を装備 10000 レベル無塵ワークショップ,300メートル/分 12 カラー高速グラビア印刷機,ドイツの技術による自動高速ブリスターマシン,八方シール製袋機などの高規格製袋設備.

ベンゼン・ケトンインク不使用。, ベンゼンフリー、ケトンフリーを使用,インクやその他の環境に優しい素材。毎日の容量は達する可能性があります。 150 トン,Safeであなたのニーズを完全に満たします,効率的で健康的.

私たちはカスタマイズされた注文を受け入れます。あなたに正しい見積もりを提供するために,以下のようにあなたの詳細が必要です:

- 数量

- 印刷色デザイン

- 素材と厚み

- サイズ

食品包装フィルムの詳しい種類やご質問はこちら, 参照してください: https://kxpack.com/product-category/plastic-film/

私たちは高品質の製品を提供しますが、それに限定されません, 競争力のある価格, すばらしいサービス, 等.