Pellicola di packaging stampata: L'evoluzione del product storytelling e della sostenibilità in 2025

Pellicola di packaging stampata

In an era where consumer attention spans are shrinking and environmental consciousness is rising, pellicola in rotolo per imballaggio stampata è emerso come un punto di svolta per i marchi di tutti i settori. Dall'alimentare e cosmetico al farmaceutico e ai beni industriali, questa soluzione di imballaggio flessibile sta ridefinendo il modo in cui vengono presentati i prodotti, protetto, e percepito. Esploriamo le tendenze, innovazioni, and strategic advantages driving its adoption in 2025.

1. Perché la pellicola in rotolo da imballaggio stampata? The Core Benefits

UN. Versatilità nel design & Funzionalità

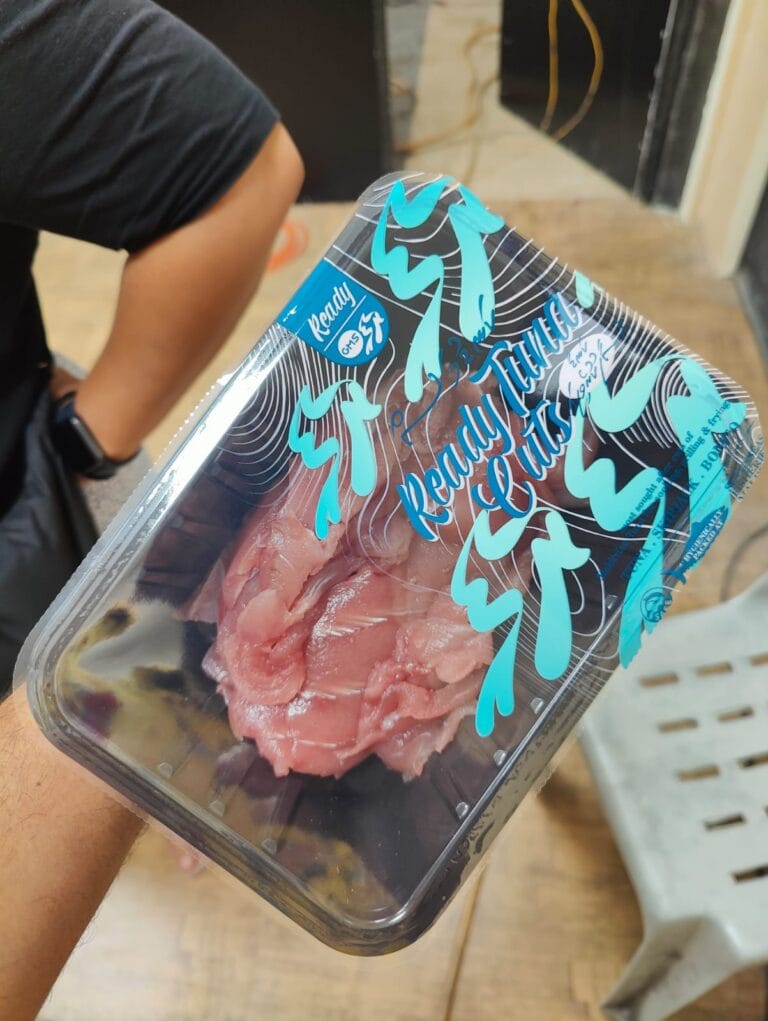

Pellicola di packaging stampata are engineered to adapt to diverse product shapes and sizes. Whether forming pouches for coffee beans, sealing fresh produce, or wrapping pharmaceuticals, these films combine durability with customization. Brands can leverage high-resolution graphics, finiture opache, or even tactile textures to create shelf-ready packaging that stands out. Ad esempio, CNG’s matte film roll, compliant with How2Recycle guidelines, demonstrates how aesthetics can align with sustainability.

B. Cost-Effective Flexibility

Low minimum print volumes and advanced form-fill-seal (FFS) machinery enable brands to launch seasonal campaigns, private labels, or limited editions without hefty upfront costs. A coffee brand, Per esempio, can switch packaging designs quarterly by adjusting roll width and cut-off lengths, ensuring freshness in both product and branding.

C. Durata di conservazione estesa & Sicurezza

Technological advancements in multilayer films and active coatings (PER ESEMPIO., antimicrobico, oxygen-scavenging) now allow printed roll films to double as protective barriers. CJ Biomaterials’ PHA-based coatings, ad esempio, offer compostable solutions that prevent microbial growth, extending the shelf life of perishables while appealing to eco-conscious consumers.

2. 2025 Tendenze che plasmano il settore

UN. Sustainability as a Non-Negotiable

The bioplastic segment is growing at a CAGR of 5%, driven by regulations and consumer demand. Brands are transitioning to films made from 30% riciclato post-consumo (PCR) plastic or compostable materials like PHA. Design Polymerics’ shift from white to black pails with PCR content exemplifies how even ancillary packaging components are evolving.

B. Imballaggio intelligente & Interattività

Embedded QR codes, Tag NFC, or temperature-sensitive inks are turning printed films into interactive storytelling tools. A skincare brand, Per esempio, could use a scannable film to share ingredient sourcing stories or usage tutorials, deepening customer engagement.

C. Dinamiche del mercato regionale

- Asia-Pacifico: Dominates due to its vast consumer base and industrial growth. Brands here prioritize cost-efficient, high-volume roll films for snacks and beverages.

- America del Nord: Leads in innovation, with brands investing in premium finishes (PER ESEMPIO., holographic prints) and recyclable structures to meet stringent sustainability standards.

3. Considerazioni chiave per i marchi

UN. Selezione dei materiali & Prestazione

Scegliere il giusto Pellicola di packaging stampata structure is critical. A multilayer film with a PET/PE/EVOH composition might be ideal for oxygen-sensitive products, while a monolithic PHA film suits compostable snack packaging. Partnering with suppliers who offer material testing and dieline templates ensures compatibility with FFS machines.

B. Printing Precision & Color Consistency

High-definition gravure or digital printing techniques now support up to 11-color designs, but brands must account for ink adhesion on recycled content. Sollex’s specialized blades, tailored for abrasive multilayer films, highlight the importance of selecting cutting tools that prevent defects during conversion.

C. Conformità normativa

With global regulations on recyclability (PER ESEMPIO., La Direttiva UE sulla plastica monouso) and food safety (FDA/EFSA), brands must verify that their printed films meet standards for direct food contact and recyclability claims.

4. Il futuro: Beyond Packaging

Pellicola di packaging stampata are evolving into brand ambassadors. Imagine a film that changes color when a product expires or a pouch that releases a fragrance when opened. Innovations like these, combined with AI-driven design tools, will enable hyper-personalized packaging at scale.

Conclusione

In 2025, printed packaging roll film is no longer just a protective layer—it’s a strategic asset. Brands that harness its flexibility, sostenibilità, and technological potential will not only reduce costs but also forge deeper connections with consumers. As the packaging films market grows at 5% CAGR, the question isn’t whether to adopt printed roll films, but how creatively you can leverage them to tell your brand’s story.

Pronti a trasformare il vostro packaging? Start by auditing your current materials, exploring bioplastic alternatives, and experimenting with interactive designs. The roll film revolution is here—and it’s printed in full color.

Fonti: Industry reports, PennPac insights, E 2025 market analyses.