Konpoze fim-manje anbalaj yon lòt kwasans

Konpoze fim-manje anbalaj yon lòt kwasans

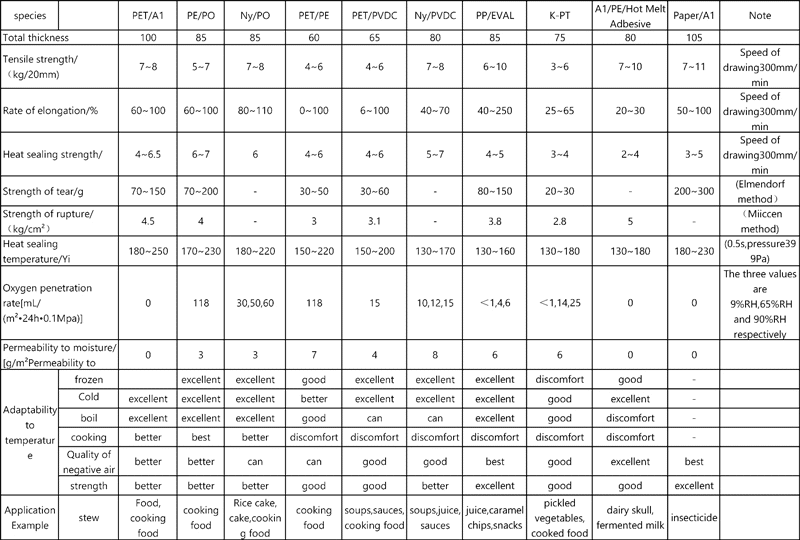

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, ka itilize nan yon seri sèten, men yon sèl materyèl pa ka gen tout pwopriyete yo nan materyèl anbalaj, pa ka satisfè kondisyon yo an jeneral nan anbalaj manje.

Se poutèt sa, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

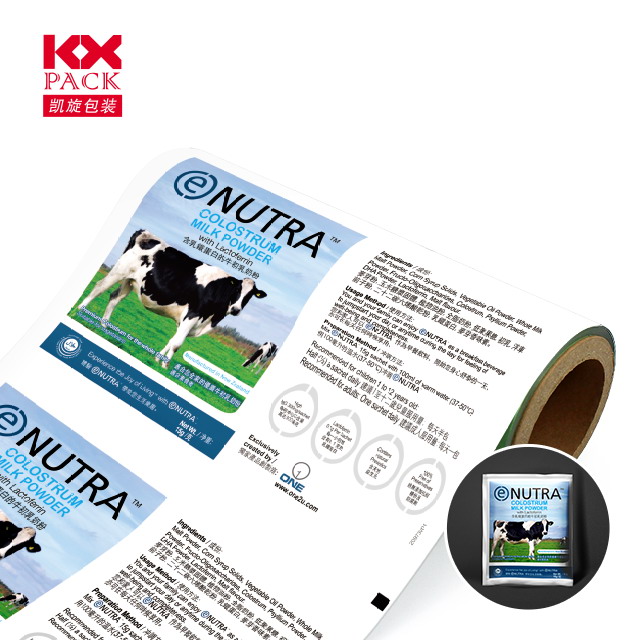

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, gwo fòs, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

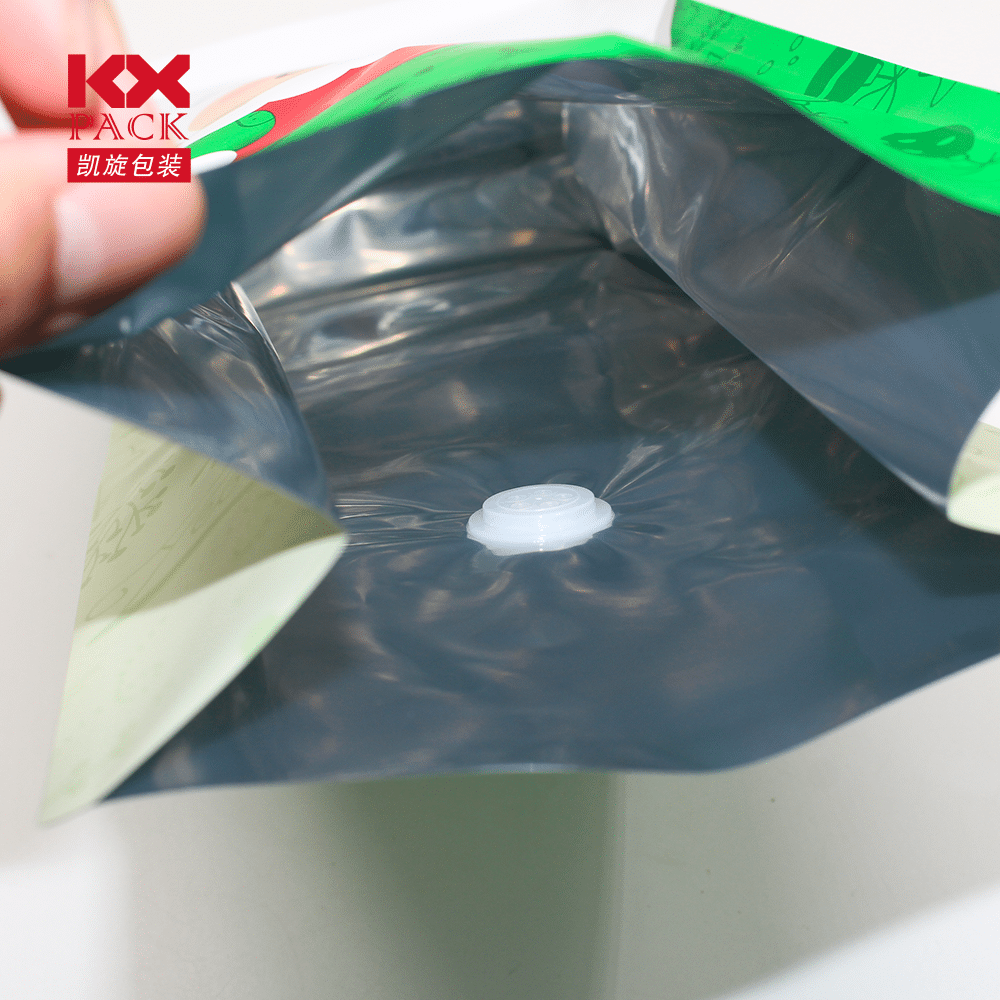

- Inner layer requirements: ki pa toksik, san gou, oil resistance, rezistans chimik

Bon, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, PET, Bopp, Pès, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

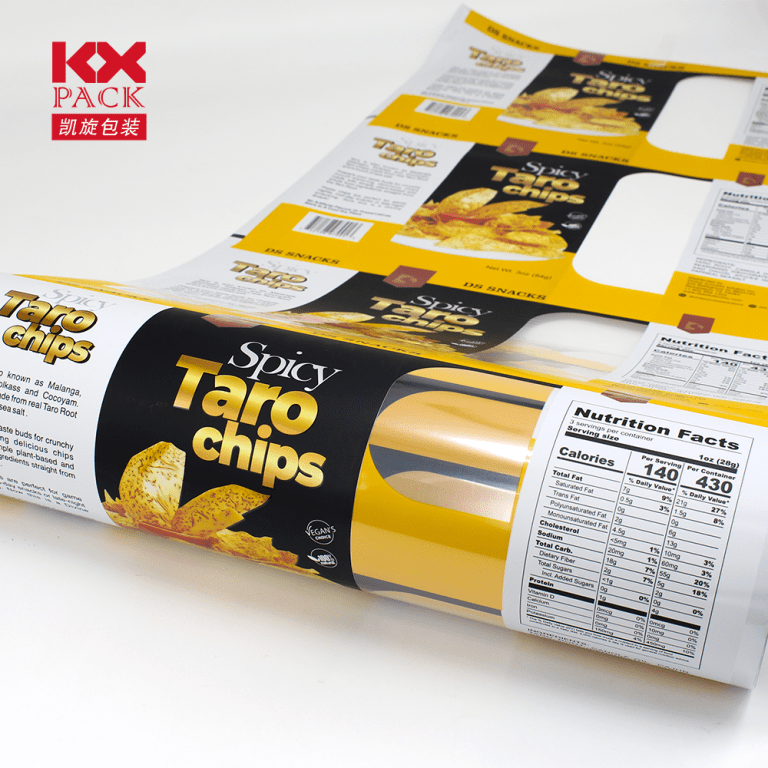

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Pa egzanp: paper /PE/AL/PE, outer layer provides printing performance, mwayen

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Ki jan yo Customize bon resiklaje fim konpoze avèk nou?

Shantou Kaixuan Emballage co, Ltd

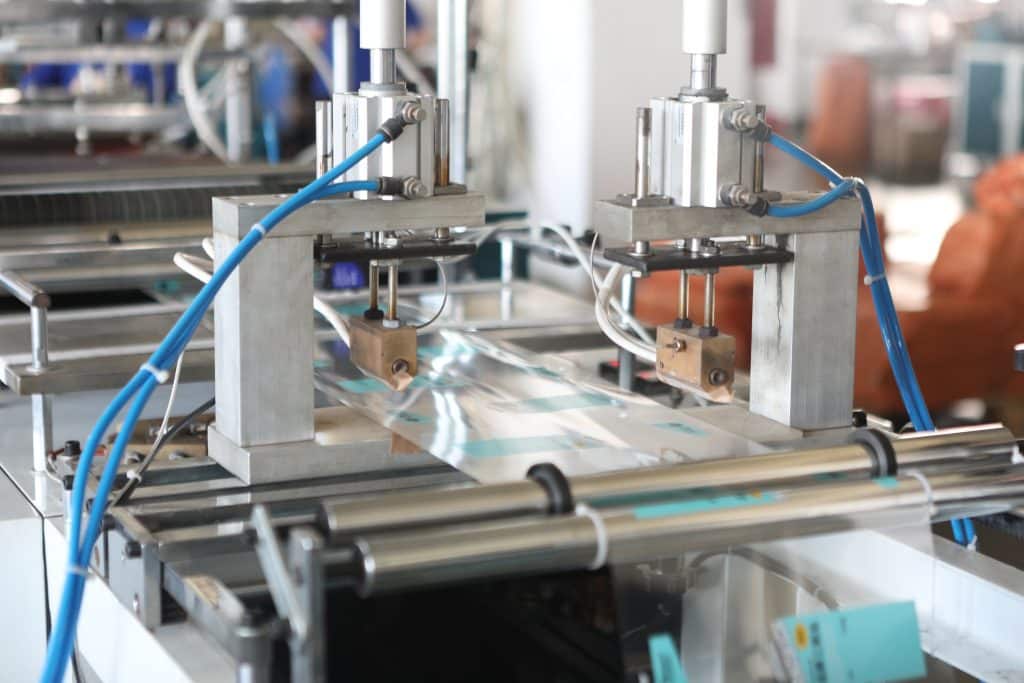

Dirèk faktori konsantre sou anbalaj sou 20 ane,espesyalman nan enprime koulè,anpoul ak sak fè.Entegre nan konsepsyon,pwodiksyon ak sale.Kaixuan faktori kouvri yon zòn nan 20000㎡,ekipe ak yon 10000 nivo atelye san pousyè,300m/min 12 koulè gwo vitès machin enprime gravure,otomatik gwo vitès anpoul machin ak teknoloji Alman,uit bò sele sak fè machin ak lòt segondè-estanda sak fè ekipman.

Pa gen Benzèn Pa gen Lank Ketonn, nou itilize benzèn gratis ak ketonn gratis,lank ak lòt materyèl ekolojik-zanmitay. Kapasite chak jou te kapab rive 150 tòn,absoliman satisfè bezwen ou yo nan Safe,Efikas ak an sante.

Nou aksepte lòd Customized. Yo nan lòd yo ofri ou yon sitasyon ki kòrèk,nou ta dwe bezwen detay ou jan pi ba a:

- Kantite

- Enpresyon koulè konsepsyon

- Materyèl ak epesè

- Gwosè

Pou plis detay kalite oswa kesyon sou fim anbalaj manje, tanpri gade: https://kxpack.com/product-category/plastic-film/

Nou bay men yo pa limite a pwodwi-wo kalite, pri konpetitif, sèvis ekselan, elatriye.