Kompozitni film-pakiranje hrane Još jedan skok

Kompozitni film-pakiranje hrane Još jedan skok

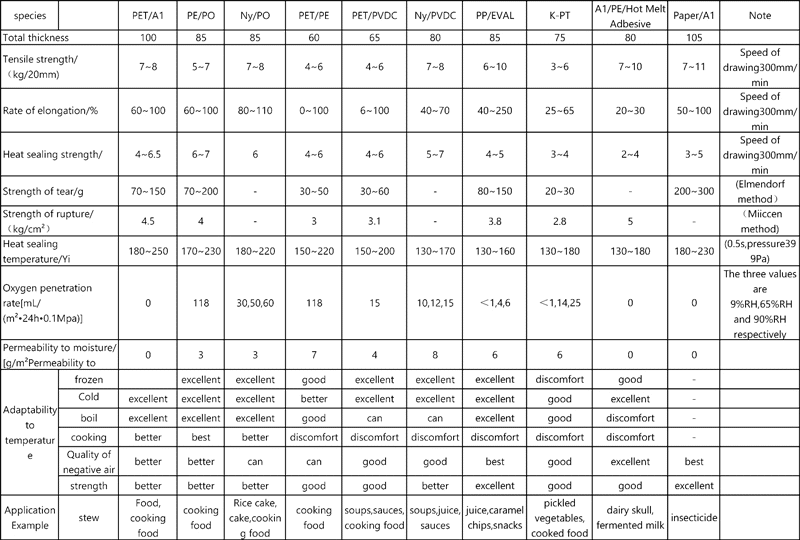

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, može se koristiti u određenom rasponu, ali jedan materijal ne može imati sva svojstva materijala za pakiranje, ne može zadovoljiti sveukupne zahtjeve pakiranja hrane.

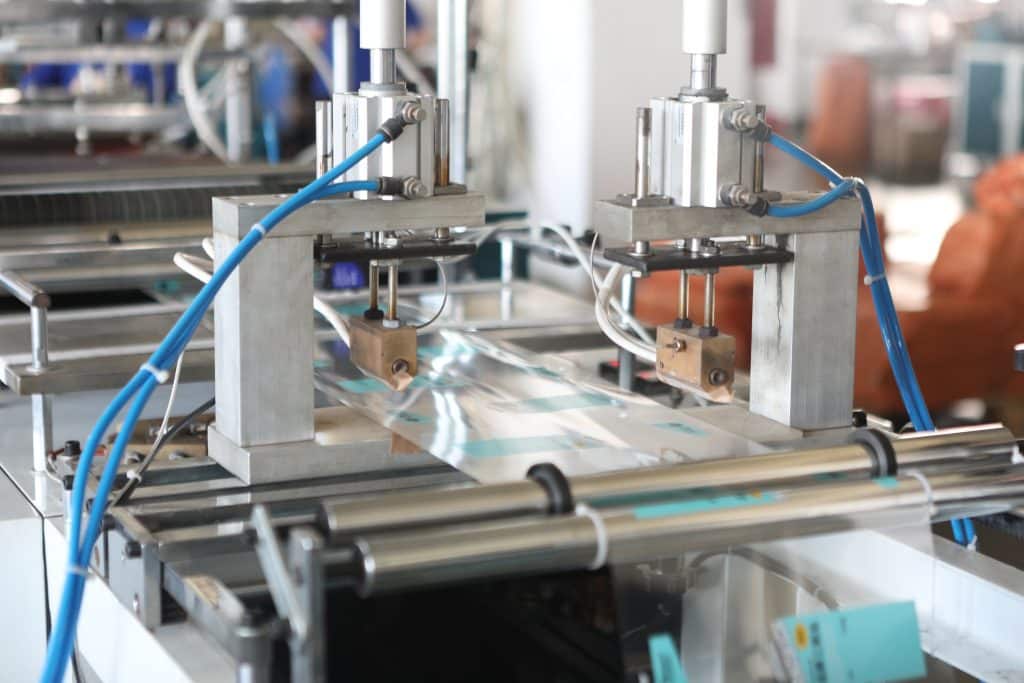

Stoga, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

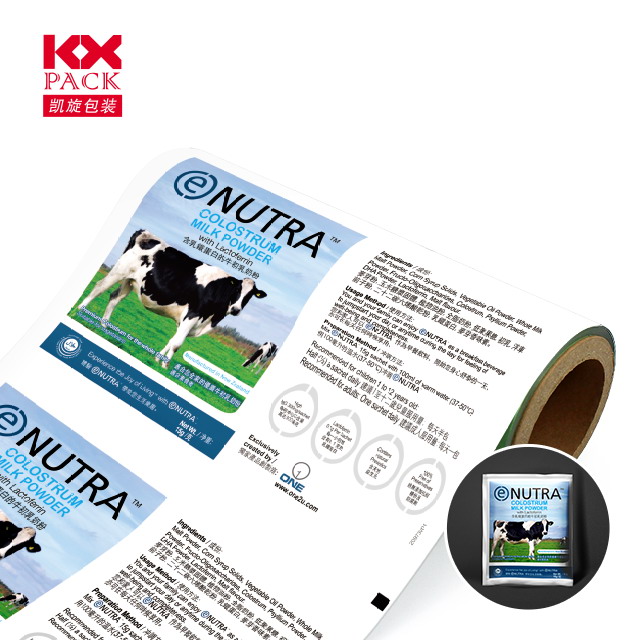

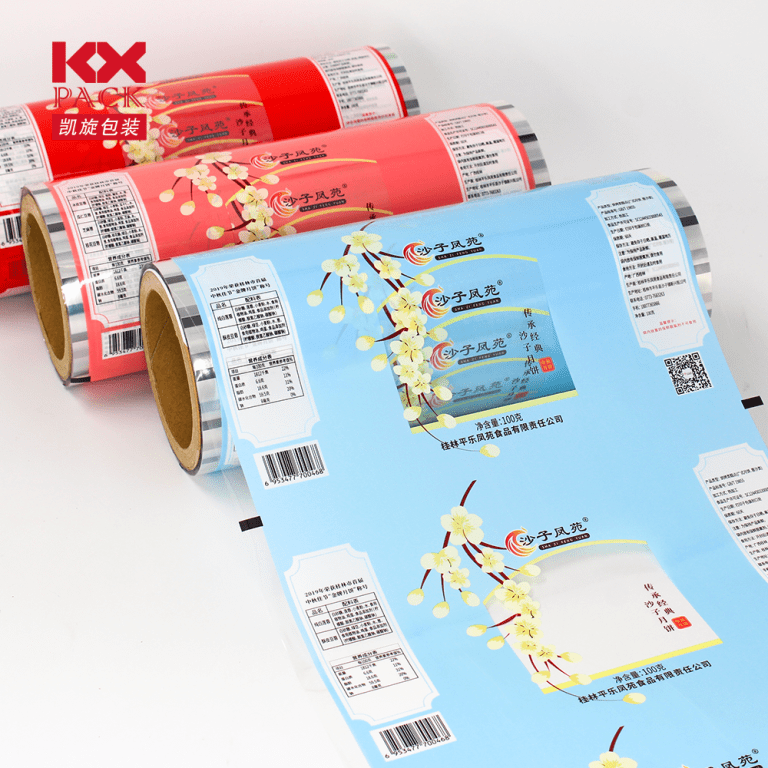

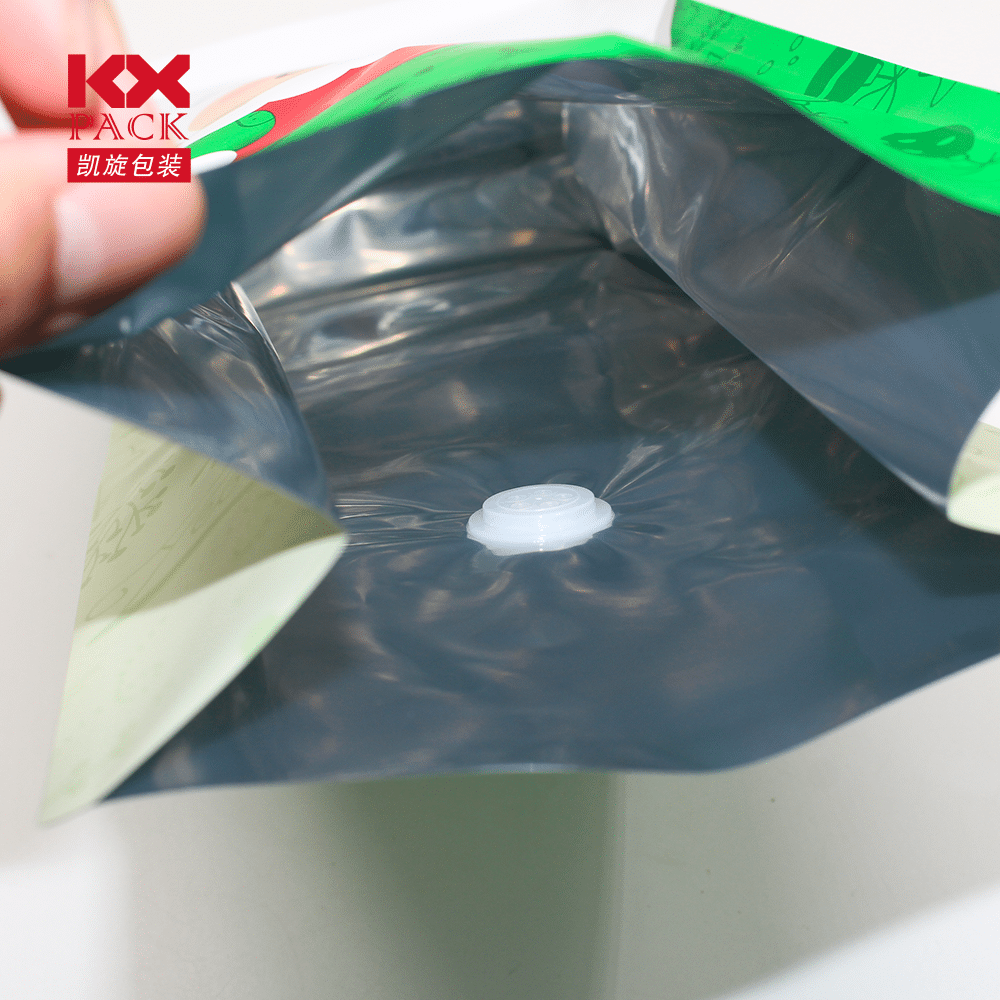

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: non-toxic, neukusan, oil resistance, chemical resistance

Good, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, EVA, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, LJUBIMAC, Bopp, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Na primjer: paper /PE/AL/PE, outer layer provides printing performance, srednji

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Kako prilagoditi dobro recikliranjee composite film with us?

Shantou Kaixuan Packaging Co., Ltd

Izravni fokus proizvodnje na pakiranje 20 godine,posebno u kolornom tisku,izrada blistera i vrećica.Integrirano u dizajnu,proizvodnja i prodaja. Tvornica Kaixuan pokriva područje od 20000㎡,opremljen sa a 10000 razina radionica bez prašine,300m/min 12 stroj za duboki tisak u boji velike brzine,automatski brzi blister stroj s njemačkom tehnologijom,stroj za izradu vrećica s osam strana i drugu opremu za izradu vrećica visokog standarda.

Bez benzena, bez ketonske tinte. U međuvremenu, koristimo bez benzena i bez ketona,tinte i drugih ekološki prihvatljivih materijala. Dnevni kapacitet mogao bi dosegnuti 150 tona,apsolutno zadovoljiti vaše potrebe u Safeu,Učinkovito i zdravo.

Prihvaćamo prilagođene narudžbe. Kako bismo vam ponudili točnu ponudu,trebali bismo trebati vaše podatke kao što je navedeno u nastavku:

- Kol

- Dizajn tiskanja u boji

- Materijali i debljina

- Veličina

Za detaljnije vrste ili pitanja o folijama za pakiranje hrane, molimo pogledajte: https://kxpack.com/product-category/plastic-film/

Nudimo, ali nismo ograničeni na proizvode visoke kvalitete, konkurentne cijene, izvrsna usluga, itd.