Film de rouleau d'emballage imprimé: L'évolution de la narration des produits et de la durabilité dans 2025

Film de rouleau d'emballage imprimé

À une époque où la capacité d’attention des consommateurs diminue et où la conscience environnementale augmente, film en rouleau d'emballage imprimé est devenu un élément révolutionnaire pour les marques de tous les secteurs. De l'alimentation et des cosmétiques aux produits pharmaceutiques et industriels, cette solution d'emballage flexible redéfinit la façon dont les produits sont présentés, protégé, et perçu. Explorons les tendances, innovations, et les avantages stratégiques qui motivent son adoption dans 2025.

1. Pourquoi un film d'emballage en rouleau imprimé? Les principaux avantages

un. Polyvalence dans la conception & Fonctionnalité

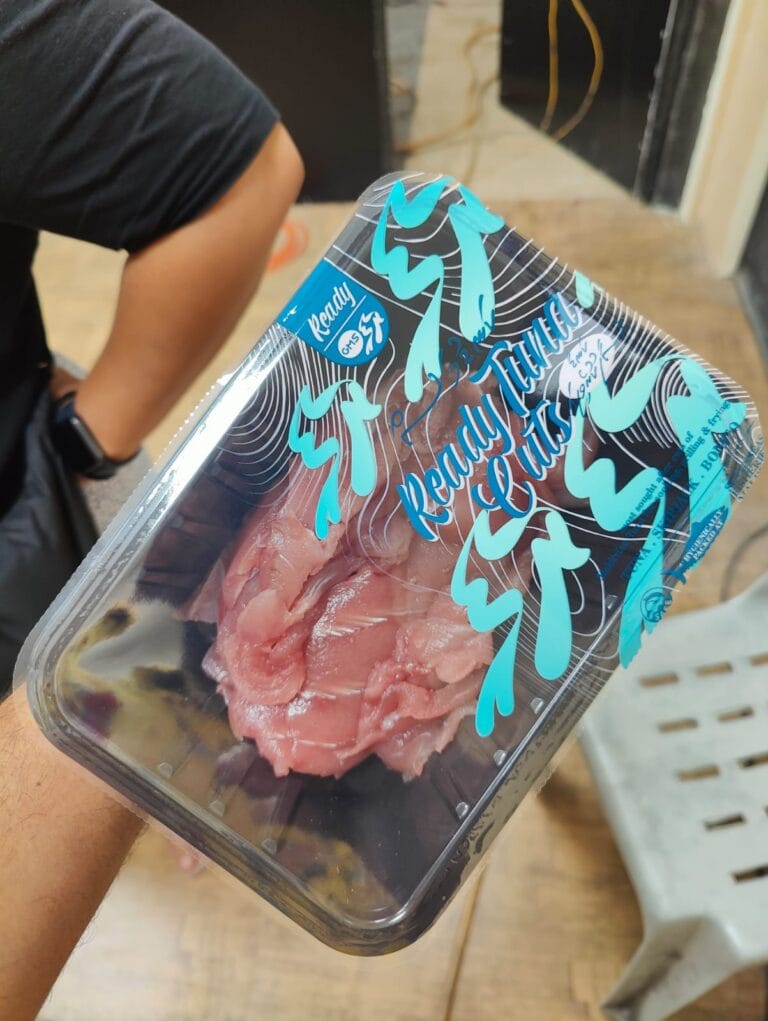

Film de rouleau d'emballage imprimé sont conçus pour s'adapter à diverses formes et tailles de produits. Qu'il s'agisse de former des sachets pour les grains de café, sceller les produits frais, ou emballage de produits pharmaceutiques, ces films allient durabilité et personnalisation. Les marques peuvent tirer parti des graphiques haute résolution, finitions mates, ou même des textures tactiles pour créer des emballages prêts à vendre qui se démarquent. Par exemple, Le rouleau de film mat de CNG, conforme aux directives How2Recycle, démontre comment l’esthétique peut s’aligner avec la durabilité.

b. Flexibilité rentable

Faibles volumes d'impression minimum et formulaire-remplissage-scellage avancé (FFS) les machines permettent aux marques de lancer des campagnes saisonnières, marques privées, ou des éditions limitées sans frais initiaux élevés. Une marque de café, Par exemple, peut changer de modèle d'emballage tous les trimestres en ajustant la largeur des rouleaux et les longueurs de coupe, assurer la fraîcheur du produit et de l'image de marque.

c. Durée de conservation prolongée & Sécurité

Avancées technologiques dans les films multicouches et les revêtements actifs (Par exemple, antimicrobien, désoxygénant) permettent désormais aux films en rouleaux imprimés de servir de barrières de protection. Revêtements à base de PHA de CJ Biomaterials, par exemple, proposer des solutions compostables qui empêchent la croissance microbienne, prolonger la durée de conservation des denrées périssables tout en attirant les consommateurs soucieux de l'environnement.

2. 2025 Tendances qui façonnent l'industrie

un. La durabilité comme élément non négociable

Le segment des bioplastiques croît à un TCAC de 5%, motivé par la réglementation et la demande des consommateurs. Les marques se tournent vers des films réalisés à partir de 30% post-consommateur recyclé (PCR) plastique ou matériaux compostables comme le PHA. Le passage de Design Polymerics des seaux blancs aux seaux noirs avec contenu PCR illustre l'évolution même des composants d'emballage auxiliaires..

b. Emballage intelligent & Interactivité

Codes QR intégrés, Balises NFC, ou les encres sensibles à la température transforment les films imprimés en outils de narration interactifs. Une marque de soin, Par exemple, pourrait utiliser un film numérisable pour partager des histoires d'approvisionnement en ingrédients ou des tutoriels d'utilisation, approfondir l’engagement client.

c. Dynamique du marché régional

- Asie-Pacifique: Domine en raison de sa vaste base de consommateurs et de sa croissance industrielle. Les marques privilégient ici la rentabilité, films en rouleaux à grand volume pour snacks et boissons.

- Amérique du Nord: Leaders en innovation, avec des marques investissant dans des finitions haut de gamme (Par exemple, impressions holographiques) et des structures recyclables pour répondre à des normes strictes de durabilité.

3. Considérations clés pour les marques

un. Sélection des matériaux & Performance

Choisir le bon Film de rouleau d'emballage imprimé la structure est essentielle. Un film multicouche avec une composition PET/PE/EVOH pourrait être idéal pour les produits sensibles à l'oxygène, tandis qu'un film PHA monolithique convient aux emballages de snacks compostables. Le partenariat avec des fournisseurs proposant des tests de matériaux et des modèles de découpe garantit la compatibilité avec les machines FFS..

b. Précision d'impression & Cohérence des couleurs

Les techniques d'héliogravure ou d'impression numérique haute définition prennent désormais en charge des designs jusqu'à 11 couleurs., mais les marques doivent tenir compte de l'adhérence de l'encre sur le contenu recyclé. Les lames spécialisées de Sollex, adapté aux films multicouches abrasifs, souligner l'importance de sélectionner des outils de coupe qui évitent les défauts lors de la conversion.

c. Conformité réglementaire

Avec une réglementation mondiale sur la recyclabilité (Par exemple, Directive plastique à usage unique de l'UE) et la sécurité alimentaire (FDA/EFSA), les marques doivent vérifier que leurs films imprimés répondent aux normes de contact alimentaire direct et aux allégations de recyclabilité.

4. L'avenir: Au-delà de l'emballage

Film de rouleau d'emballage imprimé évoluent vers ambassadeurs de la marque. Imaginez un film qui change de couleur lorsqu'un produit expire ou un sachet qui libère un parfum à l'ouverture.. Des innovations comme celles-ci, combiné avec des outils de conception basés sur l'IA, permettra un emballage hyper-personnalisé à grande échelle.

Conclusion

Dans 2025, le film d’emballage imprimé en rouleau n’est plus seulement une couche protectrice : c’est un atout stratégique. Des marques qui exploitent sa flexibilité, durabilité, et le potentiel technologique réduira non seulement les coûts, mais établira également des liens plus profonds avec les consommateurs.. Alors que le marché des films d'emballage connaît une croissance 5% TCAC, la question n’est pas de savoir s’il faut adopter des films imprimés en rouleau, mais avec quelle créativité vous pouvez les exploiter pour raconter l'histoire de votre marque.

Prêt à transformer votre emballage? Commencez par auditer vos documents actuels, explorer les alternatives aux bioplastiques, et expérimenter des conceptions interactives. La révolution du film en rouleau est là et elle est imprimée en couleur.

Sources: Rapports de l'industrie, Aperçu de PennPac, et 2025 analyses de marché.