L'impact environnemental invisible de l'emballage de rouleau de film et comment dérouter un avenir plus vert

Emballage de rouleau de film

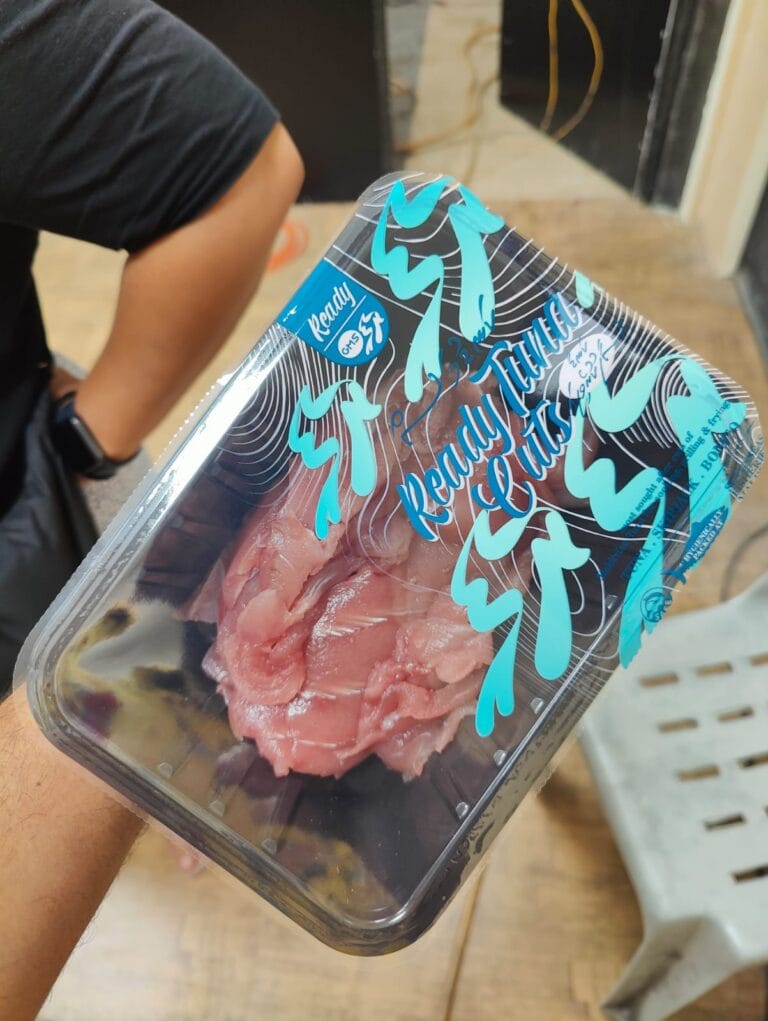

Des emballages de produits frais aux mailings e-commerce, emballage de rouleau de film - mince, Feuilles en plastique flexibles utilisées pour la protection et le scellage - est omniprésent dans la vie moderne. Tandis que son poids léger, La conception rentable semble pratique, Son empreinte environnementale raconte une histoire plus sombre. Chaque année, Des milliards de livres de déchets de gaspillage de films de rotation des déchets, océans, et écosystèmes, soulignant le besoin urgent d’une réforme systémique.

Pourquoi l'emballage en rouleaux de film est une énigme en matière de recyclage

Emballage de rouleau de film , généralement fabriqué à partir de polyéthylène basse densité (PEBD) ou polyéthylène basse densité linéaire (PEBDL), pose des défis de recyclage uniques:

- Risques de contamination:

Le film piège souvent les résidus alimentaires, étiquettes, ou des adhésifs, ce qui rend difficile le nettoyage pour le recyclage. La plupart des programmes municipaux le rejettent en raison des craintes de contamination. - Obstacles logistiques:

Contrairement aux plastiques rigides, les rouleaux de film peuvent bloquer les machines dans les installations de recyclage. Un équipement spécialisé est nécessaire pour les compacter et les traiter, qui manque à de nombreuses installations. - Dilemmes du décyclage:

Même recyclé, le film est généralement “recyclé” en produits de moindre valeur comme le bois composite ou les sacs poubelles, perpétuer un cycle de matériaux à usage unique.

Aux États-Unis, seulement 5% de Emballage de rouleau de film est recyclé chaque année, le reste finissant dans les décharges ou sous forme de détritus. À l'échelle mondiale, la situation est tout aussi désastreuse, avec un film plastique contribuant à 20% de la pollution plastique marine.

Des innovations favorisant des solutions durables en matière de rouleaux de film

Malgré ces obstacles, Les leaders de l'industrie et les startups sont des pionniers en matière d'alternatives respectueuses de l'environnement.:

- Films biodégradables et compostables

- Des entreprises comme TIPA et BioPak développent des rouleaux de film fabriqués à partir de matériaux d'origine végétale (Par exemple, maïzena, manioc) qui se décomposent dans les installations de compostage industriel au sein 180 journées.

- Ces films répondent aux normes ASTM D6400 en matière de compostabilité, offrant une alternative viable au LDPE traditionnel.

- Recyclé post-consommation (PCR) Contenu

- Des marques comme Sealed Air et Novolex intègrent 50%+ Contenu PCR dans leurs rouleaux de film, Réduire la dépendance aux plastiques vierges.

- Certains mailers utilisent désormais 100% contenu recyclé, bien que la durabilité et le coût restent des obstacles à une adoption généralisée.

- Systèmes réutilisables et consignés

- Boucle, une plateforme commerciale circulaire, s'associe à des détaillants pour proposer des emballages en film réutilisables pour les produits secs. Les clients renvoient l'emballage via des étiquettes prépayées pour le nettoyage et la réutilisation.

- Systèmes modulaires (Par exemple, distributeurs de films à longueur réglable) réduire les déchets en permettant aux utilisateurs de couper uniquement ce dont ils ont besoin.

- Alternatives sur papier

- Des innovations comme le papier kraft couché (Par exemple, Natureflex de Futamura) offrir résistance à l’eau et flexibilité, remplacement du film plastique pour certaines applications (Par exemple, produits frais).

Comment les consommateurs et les entreprises peuvent agir

- Pour les consommateurs:

- Recycler à droite: Vérifiez si votre épicerie locale accepte les films plastiques (beaucoup le font via les poubelles des vitrines). Évitez de jeter le film dans la collecte sélective.

- Choisissez des marques durables: Recherchez des étiquettes comme “100% Recyclé” ou “Compostable à la maison” sur l'emballage.

- Réduire l'utilisation: Optez pour les achats groupés, contenants réutilisables, ou magasins à emballage minimal.

- Pour les entreprises:

- Adoptez le film PCR: Transition vers des rouleaux de film avec 30 à 50 % de contenu recyclé. Collaborez avec des fournisseurs comme RJG Plastics ou Eco-Products.

- Conception de circularité: Assurez-vous que l’emballage est facilement séparable (Par exemple, pas d'étiquettes collées) et compatible avec les filières de recyclage.

- Éduquer les clients: Inclure des instructions d'élimination claires sur l'emballage et promouvoir les programmes de recyclage.

- Politique et plaidoyer:

- Soutenir la responsabilité élargie des producteurs (EPR) des lois qui obligent les fabricants à financer les infrastructures de recyclage des films.

- Plaider pour l’interdiction des films plastiques à usage unique dans les applications non essentielles (Par exemple, sacs de produits de supermarché).

Vue d'ensemble: Repenser l'emballage flexible

Emballage de rouleau de film est le symptôme d’un problème plus vaste: notre dépendance au jetable, matériaux à usage unique. Pour parvenir à une véritable durabilité, nous devons entièrement repenser les systèmes d’emballage:

- Investissez dans des modèles de réutilisation: Prioriser les contenants consignés, stations de recharge, et systèmes de dépôt.

- Matériaux innovants: Financer la recherche sur les polymères biodégradables ou les films comestibles (Par exemple, Enveloppements à base d'algues).

- Changer le comportement des consommateurs: Normaliser les sacs réutilisables, conteneurs, et achats en gros grâce à des incitations et à l'éducation.

Conclusion: Conclure un avenir plus vert

La prochaine fois que vous déroulerez un colis ou lancerez une enveloppe en plastique, pause: ce film mince pourrait persister pendant des siècles. Mais en soutenant les alternatives recyclables, plaider pour un changement de politique, et réduire la consommation, nous pouvons dérouler un avenir où les emballages protègent à la fois les produits et la planète.

Agissez maintenant:

- Recyclez votre Emballage de rouleau de film dans les points de dépôt locaux.

- Passez à des marques utilisant des films compostables ou à contenu recyclé.

- Partagez cette publication pour sensibiliser au coût environnemental caché du cinéma.

Ensemble, nous pouvons inverser la tendance des déchets plastiques – un rouleau flexible à la fois.

Sources: Fondation Ellen MacArthur, EPA, Résumé de l'emballage, TIPA Corp..