Película de embalaje impresa: La revolución visual redefiniendo el atractivo del producto en 2025

Película de embalaje impresa

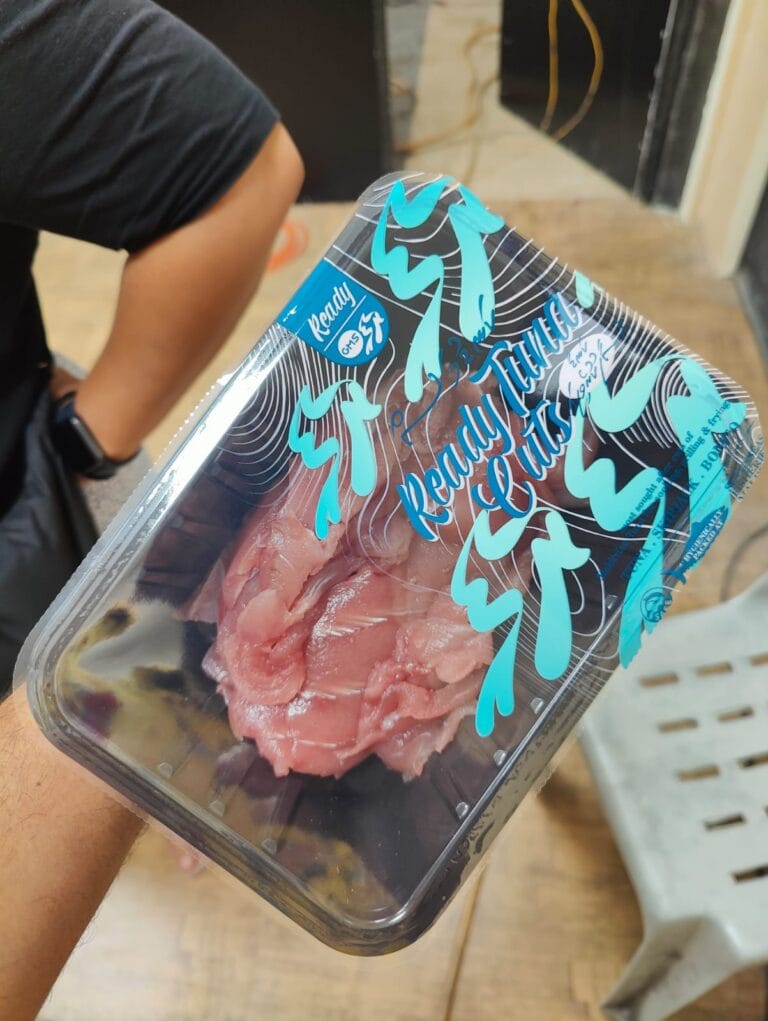

En los pasillos abarrotados del comercio minorista moderno, Donde los consumidores toman decisiones de compra de segundos de división, El papel del empaque ha evolucionado de mera protección a una herramienta de marca estratégica. Entre las innovaciones que impulsan esta transformación, película de embalaje impreso se destaca como un punto de inflexión, Combinar la funcionalidad con la narración visual para crear experiencias memorables del consumidor.

¿Por qué la película de embalaje impresa?? El imperativo de la marca

Película de embalaje impresa Ya no se trata sólo de envolver productos: son lienzos dinámicos para la identidad de marca.. A diferencia de las películas transparentes, que dependen de etiquetas externas, Las películas impresas integran logotipos., esquemas de color, datos nutricionales, e incluso realidad aumentada (Arkansas) Se activa directamente en el embalaje.. Esta perfecta integración garantiza:

- Reconocimiento instantáneo: Gráficos llamativos y marcas consistentes en todas las líneas de productos mejoran la visibilidad en los estantes. Por ejemplo, una marca de refrigerios que utiliza impresión digital de alta resolución en su película multicapa puede mostrar imágenes vibrantes de productos y códigos QR que enlazan con videos de recetas.

- Cumplimiento regulatorio: Información crítica como ingredientes., instrucciones de uso, y las advertencias de seguridad están integradas permanentemente, reducir el riesgo de etiquetado incorrecto. Esto es particularmente vital para industrias como la cosmética., donde las exigencias regulatorias de claridad son estrictas.

- Mensajes de sostenibilidad: A medida que aumenta la conciencia ecológica, Las marcas aprovechan las películas impresas para resaltar la reciclabilidad., biodegradabilidad, o reducciones de la huella de carbono, alinearse con los valores del consumidor.

Avances tecnológicos: De la impresión al píxel

El Película de embalaje impresa el mercado está aumentando, proyectado para alcanzar $179.18 mil millones por 2034, Impulsado por innovaciones en técnicas de impresión y ciencia de materiales.. Las tendencias clave incluyen:

- Dominio de la impresión digital: Las impresoras digitales de alta resolución permiten una rentabilidad, personalización a corto plazo, Permitir a las marcas lanzar diseños de edición limitada o campañas regionales sin grandes costos de herramientas..

- Integración de envasado inteligente: Las películas incorporan ahora etiquetas RFID, tintas sensibles a la temperatura, y capas AR. Imagine escanear una bolsa de café para ver su historia de origen o recibir alertas de frescura a través de una aplicación de teléfono inteligente..

- Compuestos de materiales avanzados: Las películas multicapa combinan capas de barrera. (P.EJ., EVOH para resistencia al oxígeno), abrigos termosellables, y sustratos reciclables. Por ejemplo, un bopet (tereftalato de polietileno orientado biaxialmente) La película con tinta impresa y una capa adhesiva biodegradable ofrece durabilidad y sostenibilidad..

Aplicaciones específicas de la industria

Las películas impresas atienden a diversos sectores, cada uno con demandas únicas:

- Alimento & Bebida: Películas resistentes a la grasa para virutas., capas de barrera aromática para café, y diseños resistentes a los pliegues para refrigerios para llevar. Una marca de productos lácteos podría utilizar un laminado impreso con protección UV para prolongar la vida útil y al mismo tiempo mostrar imágenes frescas de la granja..

- Cuidado personal & Productos cosméticos: Tubos y bolsas con tintas metálicas., texturas en relieve, y diseños de envases recargables. Las líneas de cuidado de la piel de lujo a menudo optan por películas con acabado mate con marcas holográficas para transmitir un atractivo premium..

- Industrial & Químicos: Las películas para empaquetar leña o productos de limpieza ahora incluyen advertencias de seguridad e instrucciones de manejo impresas., reducir los accidentes laborales.

Desafíos & Compensaciones de sostenibilidad

A pesar de sus ventajas, La película de embalaje impresa se enfrenta a un escrutinio por su impacto medioambiental. Las tintas y laminados tradicionales pueden complicar el reciclaje, impulsando innovaciones como:

- Tintas a base de agua: Reducir las emisiones de COV y mejorar la reciclabilidad.

- Estructuras monomateriales: Películas hechas de un solo tipo de polímero. (P.EJ., solo educación física) para simplificar el reciclaje posconsumo.

- Aditivos biodegradables: Películas que incorporan compuestos de origen vegetal que se descomponen en condiciones de compostaje industrial..

Las marcas deben equilibrar la estética con la ecorresponsabilidad. Por ejemplo, un tostador de café podría cambiar de un laminado PET/PE impreso a una película mono-PE reciclable con impresión digital, sacrificar parte del rendimiento de la barrera por la circularidad.

El futuro: Interactivo & Embalaje circular

Mirando hacia adelante, Las películas impresas serán aún más inteligentes y sostenibles.. Las predicciones incluyen:

- Tintas comestibles: Impresión de marcas directamente en películas comestibles para confitería o productos farmacéuticos..

- Superficies autorreparadoras: Películas que reparan rayones menores para mantener el atractivo visual durante todo el ciclo de vida del producto..

- Integración de cadena de bloques: Códigos QR vinculados a plataformas blockchain para un seguimiento transparente de la cadena de suministro.

Conclusión: El packaging como embajador de la marca

La película de embalaje impresa ya no es una capa pasiva: es un participante activo en el recorrido del consumidor.. Fusionando la impresión de vanguardia, ciencia de materiales, y sostenibilidad, Las marcas pueden transformar el embalaje en un medio narrativo que impulse la lealtad y la diferenciación.. A medida que el mercado crece, Las marcas que dominen este arte liderarán el camino en un panorama cada vez más competitivo..

Listo para elevar su embalaje? Explore cómo las películas impresas pueden transformar la primera impresión (y la última) de su producto.

Fuentes: PennPac, Solex, MercadosyMercados, Ciencia Directa