Navegar por el futuro del envasado de alimentos: Los principales proveedores de películas de foca alimentaria que conduce innovación

Envasado de alimentos

Lo global Envasado de alimentos industry is undergoing a transformative shift, Con el empaque de películas de foca de alimentos emergiendo como piedra angular de la sostenibilidad, eficiencia, y seguridad del producto. Valued at 60.84billón2024∗∗,themarketisprojectedtosoarto∗∗122.6 billion by 2035, growing at a CAGR de 6.6%. Este aumento es alimentado por la creciente demanda de los consumidores de frescos, comida de alta calidad, Regulaciones de seguridad estrictas, and a growing emphasis on eco-friendly materials. In this dynamic landscape, leading suppliers are redefining packaging standards through cutting-edge technologies and sustainable solutions.

Key Trends Shaping the Market

- Sustainability at the Forefront

- Consumers and regulators alike are pushing for recyclable, biodegradable, and plant-based films. Suppliers like Lacerta Group y Trioworld are pioneering materials with up to 30% contenido reciclado, reducing plastic waste without compromising performance.

- Innovaciones como Seal N’ Flip™—a bottom-lidding film design—cut plastic use by 20% while enhancing product visibility, a trend adopted by retailers like Walmart and Kroger for grab-and-go sections.

- Smart Packaging Technologies

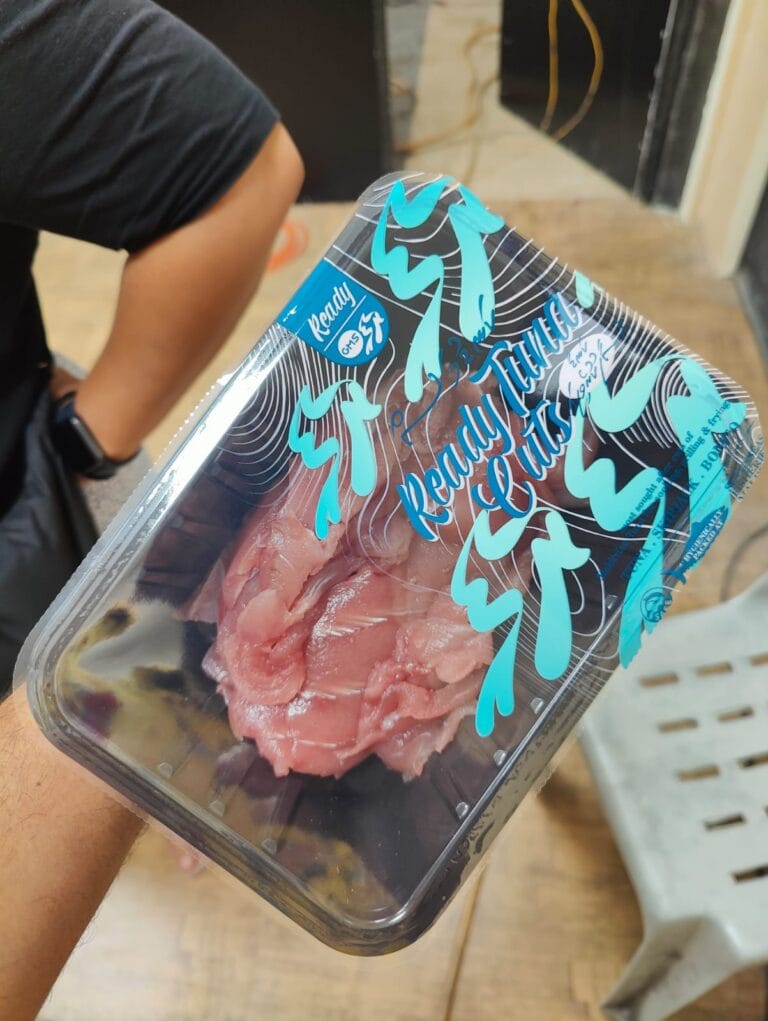

- AI-driven quality monitoring and freshness indicators are being integrated into films. Por ejemplo, Tecpacking Group’s oxygen-scavenging films extend shelf life by 50% for perishables like meat and seafood.(Envasado de alimentos)

- RTG Films specializes in high-barrier lock-seal films that maintain freshness for bakery items and processed cheeses, leveraging multilayer structures to block moisture and oxygen.(Envasado de alimentos)

- Customization for Diverse Applications

- De comida congelada a ready-to-eat meals, Envasado de alimentos suppliers offer tailored solutions. Profol Americas provides anti-fog films for refrigerated produce and peelable lidding for microwaveable trays, ensuring convenience across food categories.

- Oliver Packaging's Speedseal Films cater to paper and plastic trays, with gauges adjustable for snacks or full-course meals, streamlining operations for foodservice giants like Sysco and Compass Group.

Top Suppliers Leading the Charge

- Lacerta Group (Mansfield, MA)

- Especialidad: Engineered films for high-pressure processing (HPP) and divided containers.

- Innovación: Su Fresh N’ Sealed line features tamper-proof, recyclable PET containers with tight film seals, ideal for salads and deli items.

- Trioworld (Global)

- Especialidad: Polipropileno (PÁGINAS) and polyethylene (EDUCACIÓN FÍSICA) films for lamination and form-fill-seal machines.

- Sostenibilidad: Offers films with 20% reciclado posconsumo (PCR) content, compliant with EU and FDA regulations.

- Paquete KX & Guangdong Tianchen (Porcelana)

- Market Dominance: Asia-Pacific leaders supplying cost-effective, high-performance films for meat and poultry.

- Tech Edge: Advanced coating technologies that reduce film thickness by 15% while maintaining barrier properties.

- Brentwood Plastics (St. Louis, MO)

- Niche Solutions: Breathable films for fresh produce and bone-guard films for meat packaging, preventing punctures during transit.

- Oliver Packaging (Wisconsin, EE.UU)

- Integrated Systems: Combines tray sealing machines, durable trays, and efficient films into a single workflow, cutting labor costs by 30% for clients like Panera Bread.(Envasado de alimentos)

Desafíos y oportunidades

While the market thrives, suppliers face hurdles:

- Material Costs: Fluctuating prices for biodegradable resins like PLA and PHA.

- Cumplimiento regulatorio: Navigating varying standards across regions (P.EJ., Directiva de plásticos de un solo uso de la UE vs. FDA guidelines).

Todavía, these challenges spur innovation. Por ejemplo, Zhejiang Haibin’s hybrid films blend bio-based polymers with traditional plastics, balancing cost and sustainability.

El camino por delante

el futuro de Envasado de alimentos lies in collaboration y tech integration. Suppliers are partnering with food giants like Nestlé and Unilever to co-develop solutions aligned with net-zero goals. Mientras tanto, startups like EcoFlex Packaging are experimenting with algae-based films that decompose in seawater, hinting at a circular economy future.

For businesses seeking a competitive edge, partnering with agile suppliers likeTecpacking Group (for smart films) oProfol Americas (for custom structures) can unlock opportunities to reduce waste, mejorar el atractivo en los estantes, y satisfacer las demandas en evolución del consumidor.

Pensamiento final: As the industry evolves, the suppliers who prioritizeinnovación, sostenibilidad, ycustomer-centric design will dominate the $122.6 billion market of tomorrow. Stay ahead by exploring partnerships that transform packaging from a cost center into a value driver.

Explore the latest trends and connect with top suppliers at industry events likePack Expo oInterpack 2026! 🌍📦