Embalaje de comida de cine compuesto otro salto

Embalaje de comida de cine compuesto otro salto

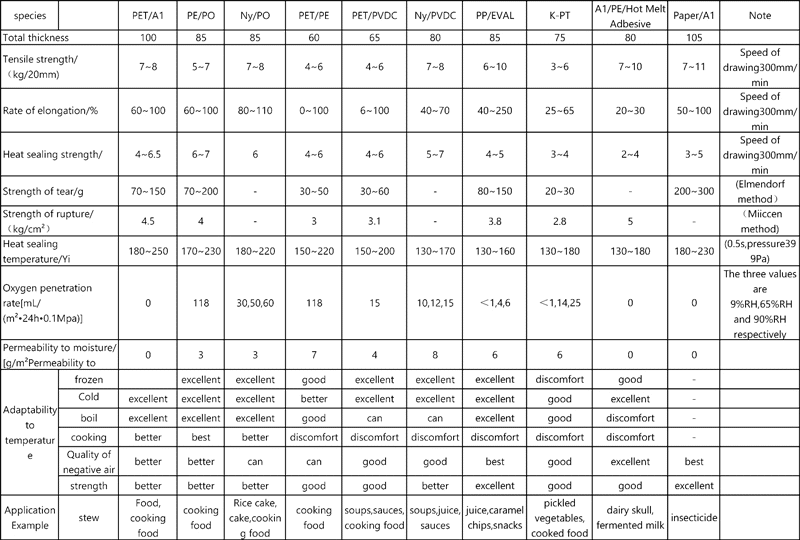

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, se puede usar en un rango determinado, Pero un solo material no puede tener todas las propiedades de los materiales de embalaje, no puede cumplir con los requisitos generales de los envases de alimentos.

Por lo tanto, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

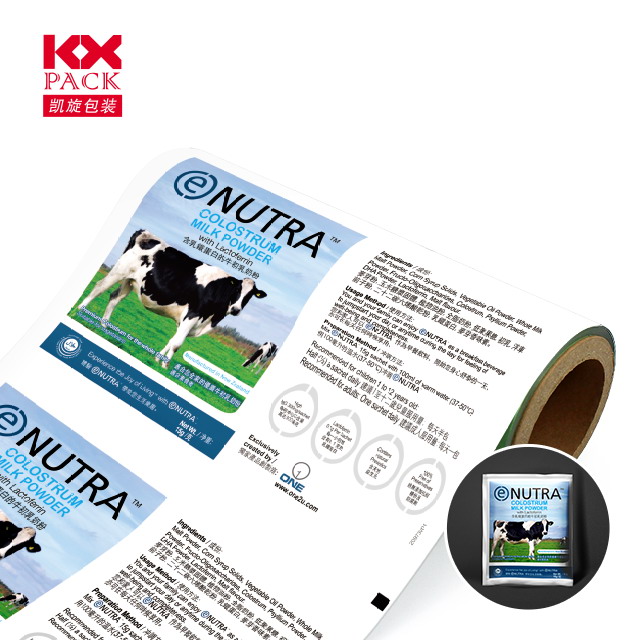

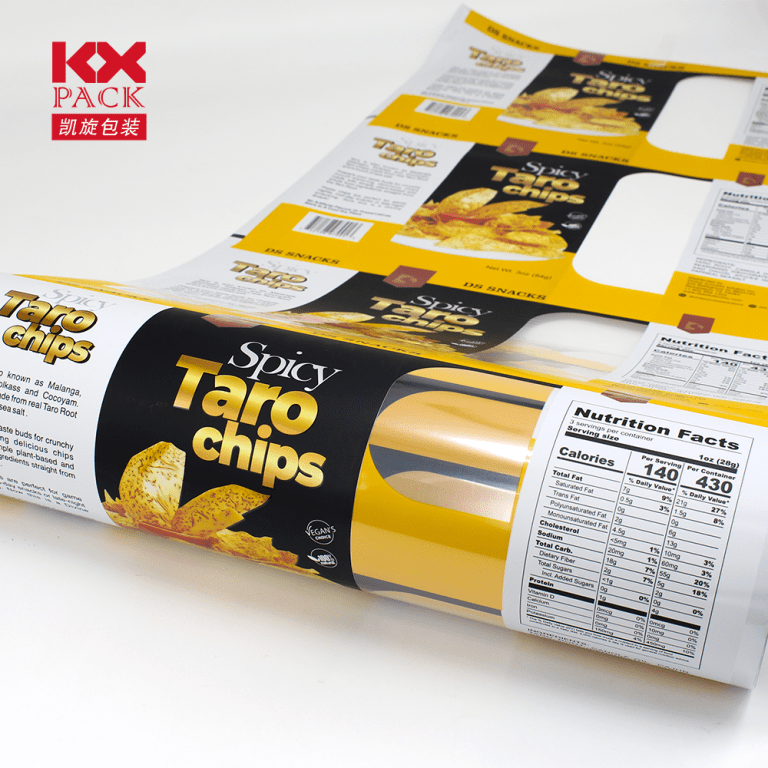

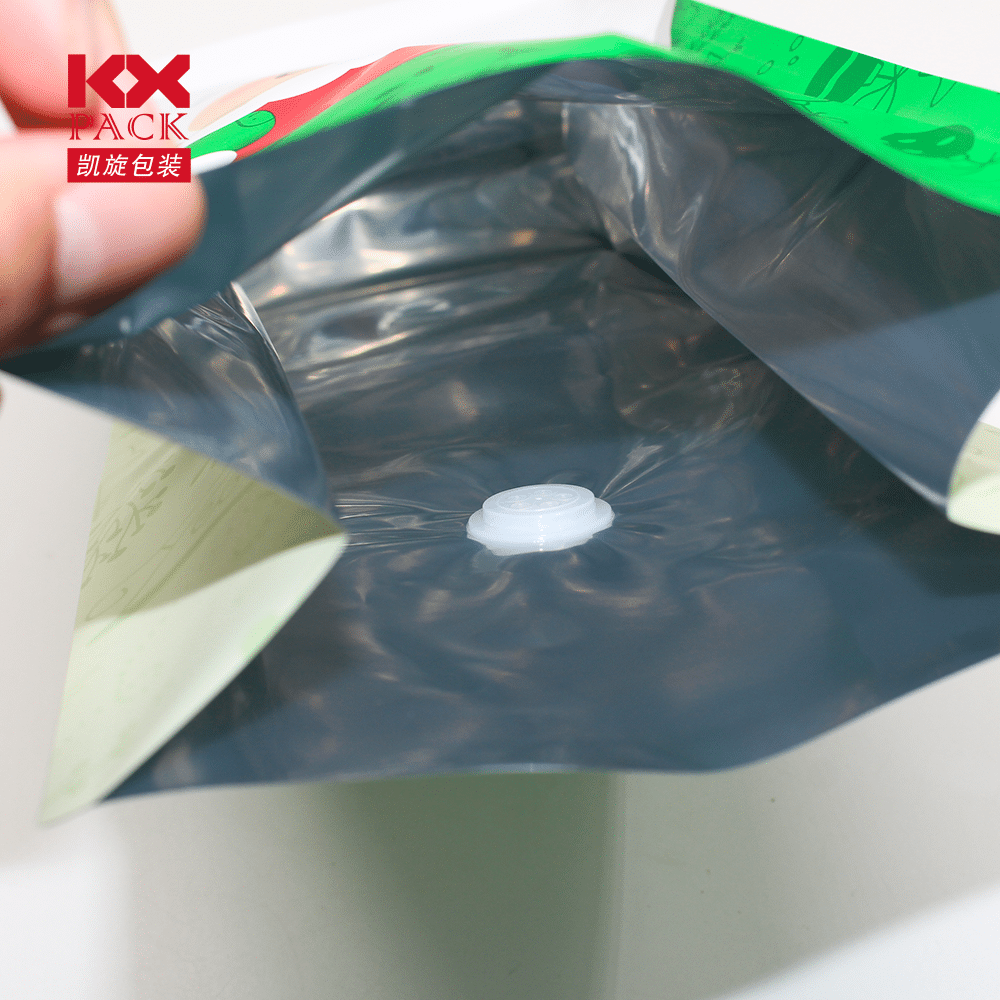

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, high strength, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: no tóxico, insípido, oil resistance, chemical resistance

Bueno, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, Eva, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, MASCOTA, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Por ejemplo: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

How to customize good recyclmi composite film with us?

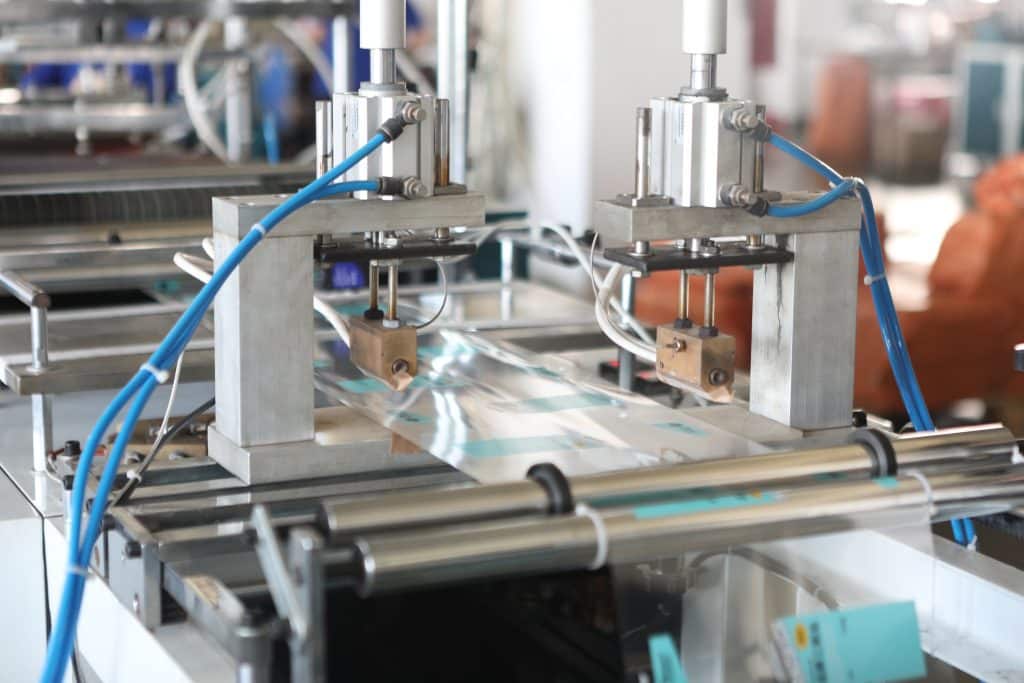

Embalaje Co., Ltd de Shantou Kaixuan

Enfoque directo de la manufactura en el empaque sobre 20 años,especialmente en impresión a color,Fabricación de blister y bolsas. Integrado en el diseño.,producción y venta. La fábrica de Kaixuan cubre un área de 20000㎡,equipado con un 10000 taller nivelado sin polvo,300m/min 12 Máquina de impresión en huecograbado de alta velocidad en color,Blister automático de alta velocidad con tecnología alemana,Máquina para fabricar bolsas con sellado de ocho lados y otros equipos para fabricar bolsas de alto estándar.

Sin benceno ni tinta cetona. Mientras tanto, Usamos libre de benceno y libre de cetonas.,tinta y otros materiales ecológicos. La capacidad diaria podría alcanzar 150 montones,Satisfaga absolutamente sus necesidades en Safe,Eficiente y Saludable.

Aceptamos pedidos personalizados. Para poder ofrecerle un presupuesto correcto,Deberíamos necesitar sus datos como se muestra a continuación.:

- Cantidad

- Diseño de color de impresión.

- Materiales y espesor

- Tamaño

Para tipos más detallados o preguntas sobre películas de envasado de alimentos, por favor refiérase a: https://kxpack.com/product-category/plastic-film/

Ofrecemos, entre otros, productos de alta calidad., Precios competitivos, excelente servicio, etc..