L'evolució del film d'embalatge flexible: Sostenibilitat, Innovació, i Impacte en el consumidor

Film Flexible Packaging

En l'actual panorama de consum ràpid, flexible packaging film has emerged as a cornerstone of modern product protection and convenience. Des d'aliments i begudes fins a productes farmacèutics i articles de cura personal, aquest lleuger, El material versàtil està remodelant les indústries equilibrant la funcionalitat, rendibilitat, i responsabilitat mediambiental. Aprofundim en les últimes tendències, reptes, and breakthroughs in flexible packaging films that are driving the future of sustainable packaging.

1. What is Flexible Packaging Film?

Film Flexible Packaging refers to non-rigid materials used to wrap, foca, or contain products. Commonly made from polymers like polietilè (PE), polipropilè (PP), polièster (PET), and biodegradable alternatives, these films offer advantages such as:

- Lightweight design: Reduces shipping emissions and material costs.

- Propietats de barrera: Protects against moisture, oxigen, UV light, i contaminants.

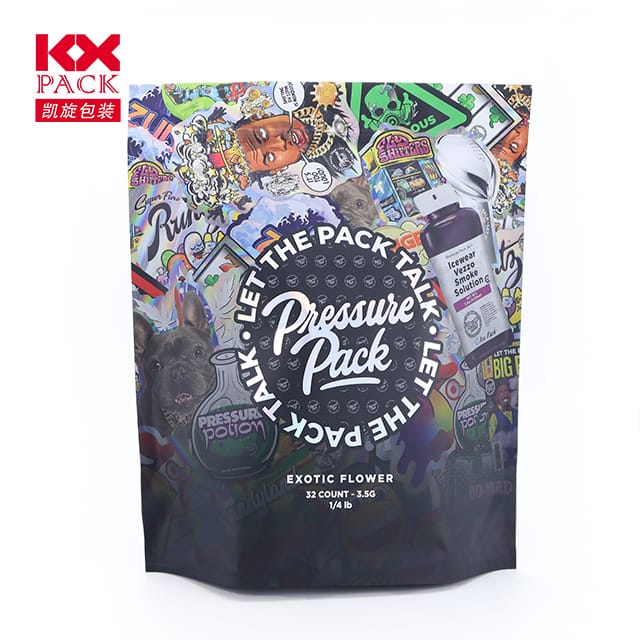

- Personalització: Enables branding via high-quality printing and unique shapes.

- Extended shelf life: Preserves product freshness, crucial for perishables.

2. Sostenibilitat: The Driving Force

The packaging industry faces mounting pressure to minimize waste and carbon footprints. Flexible films are adapting through:

una. Materials biodegradables i compostables

- PLA (Àcid polilàctic): Derived from renewable resources like corn starch, PLA decomposes in industrial composting facilities.(Film Flexible Packaging)

- PHA (Polyhydroxyalkanoates): A biodegradable polymer produced by bacteria, ideal for marine-degradable applications.

- Paper-Based Laminates: Combining paper with bio-plastics for recyclable or compostable solutions.

Marques comTIPA Corp iNatureworks are pioneering compostable films that meet industrial composting standards (P., EN 13432), offering a viable alternative to traditional plastics.

b. Monomaterials reciclables

Estructures mono-materials (P., all-PE or all-PP films) simplify recycling by eliminating multi-layer incompatibilities. Innovacions comAmcor’s AmLite HeatFlex Recyclable use single-polymer barriers to maintain performance while enabling circularity.

c. Reciclat post-consum (PCR) Contingut

Incorporating recycled plastics into flexible films reduces virgin material use. Per exemple, Dow’s RecycleReady technology allows polyethylene films to be recycled through store drop-off programs.

3. Avenços Tecnològics

una. High-Barrier Films for Longer Shelf Life

Advanced coatings and nanotechnology enhance barrier properties without adding bulk. Per exemple, silicon oxide (SiOx) and aluminum oxide (AlOx) coatings provide oxygen and moisture barriers comparable to metalized films but with recyclability benefits.

b. Active and Smart Packaging

- Oxygen Scavengers: Integrated into films to extend product freshness (P., Mitsubishi Gas Chemical’s Ageless®).

- Temperature Indicators: Color-changing labels that alert consumers to spoilage risks.

- QR Codes and NFC Tags: Enable traceability and consumer engagement via smartphones.

c. Lightweighting and Thinner Gauges

Manufacturers are reducing film thickness without sacrificing strength. Per exemple, Borealis’ Borstar® technology produces ultra-thin PE films that cut material use by up to 30%.

4. Challenges and the Road Ahead

Despite progress, hurdles remain:

- Infraestructura de reciclatge: Many flexible films are difficult to recycle due to multi-layer designs or contamination.

- Cost vs. Sostenibilitat: Biodegradable materials often cost more than conventional plastics.

- Educació del Consumidor: Misconceptions about compostability (P., home vs. industrial composting) hinder adoption.

Solutions on the Horizon:

- Chemical Recycling: Turning mixed plastics into raw materials for new films (P., PureCycle Technologies).

- Standardized Labels: Clearer recycling/composting instructions to reduce confusion.

- Policy Support: Extended Producer Responsibility (EPR) laws incentivizing eco-design.

5. The Consumer Perspective

Modern shoppers prioritize sustainability but demand uncompromised quality. Brands must balance:

- Conveniència: Easy-to-open, resealable films for on-the-go lifestyles.

- Transparència: Clear messaging about eco-attributes (P., “100% Reciclable” o “Compostable a la llar”).

- Aesthetics: High-definition printing to maintain brand appeal.

Conclusió: A Flexible Future

Flexible packaging film is at a crossroads—where innovation meets responsibility. The shift toward sustainable materials, coupled with smart packaging technologies, promises a future where products are protected, waste is minimized, and the planet thrives.

Crida a l'acció:

- Consumidors: Support brands using recyclable/compostable films and advocate for better recycling infrastructure.

- Manufacturers: Invest in R&D for mono-material designs and closed-loop systems.

- Policymakers: Enforce stricter eco-standards and incentivize circular economy practices.

Junts, we can turn flexible packaging into a symbol of progress—not pollution. 🌍♻️

Fonts: Flexible Packaging Association, Smithers Pira, Dow Chemical, Amcor, and industry sustainability reports.