كيفية اختيار فيلم تغليف المواد الغذائية المناسب لمنتجاتك

جدول المحتويات

أنا. مقدمة

1.1 الدور الحاسم لتغليف المواد الغذائية

التغليف المناسب أمر حيوي للحفاظ على الجودة, نضارة, وسلامة المنتجات الغذائية. يحمي العناصر من الملوثات الخارجية, أكسدة, فقدان الرطوبة, وغيرها من العوامل التي قد تؤدي إلى تلفها. يلعب التغليف أيضًا دورًا تسويقيًا رئيسيًا من خلال جذب المستهلكين وتوصيل معلومات المنتج. بهذه الأهمية, يعد اختيار فيلم تغليف المواد الغذائية المناسب أمرًا بالغ الأهمية لمصنعي المواد الغذائية.

1.2 أفلام تغليف الأغذية – الحاجز الأساسي

تشكل أفلام التغليف الحاجز الأساسي بين المنتج الغذائي والبيئة الخارجية. وهي عادة الطبقة الأعمق التي تتصل مباشرة بالمادة الغذائية. يحافظ فيلم التغليف المثالي على الظروف الجوية المرغوبة, يمنع هجرة الرطوبة, ويحجب الضوء, الروائح, الغازات, والكائنات الحية الدقيقة التي يمكن أن تؤدي إلى تدهور جودة المنتج أو تشكل مخاطر صحية.

ثانيا. أنواع أفلام التغليف

2.1 أفلام بلاستيكية

الأفلام البلاستيكية مثل البولي إيثيلين, البولي بروبيلين, وكان كلوريد البولي فينيل منذ فترة طويلة من المواد القياسية نظرًا لخصائصها الحاجزة الممتازة, متانة, وفعالية التكلفة. لكن, وقد دفعت المخاوف البيئية إلى استكشاف حلول بديلة.

2.2 خيارات بيولوجية وقابلة للتحلل الحيوي

لمعالجة قضايا الاستدامة, أفلام ذات أساس حيوي وقابلة للتحلل الحيوي مشتقة من موارد متجددة مثل حمض البوليلاكتيك (جيش التحرير الشعبى الصينى), نشا, السليلوز, وقد ظهرت الشيتوزان. مع تقديم مزايا صديقة للبيئة, غالبًا ما تواجه هذه المواد تحديات في مطابقة أداء الأفلام البلاستيكية التقليدية.

2.3 أفلام متعددة الطبقات والمركبة

من خلال الجمع بين البوليمرات المختلفة, يمكن تصميم الأفلام متعددة الطبقات والمركبة لتحقيق خصائص وظيفية محددة مصممة خصيصًا لمختلف أنواع الأطعمة. تتغلب هذه الهياكل المتقدمة على القيود المادية الفردية لتوفير خصائص عازلة فائقة.

ثالثا. الاعتبارات الرئيسية في اختيار فيلم تغليف المواد الغذائية

3.1 خصائص المنتج الغذائي

يعد تكوين المنتج الغذائي نفسه هو المحدد الرئيسي لاحتياجات التعبئة والتغليف. تتطلب الأطعمة عالية الرطوبة حواجز بخار الماء الممتازة, بينما تتطلب العناصر الدهنية حواجز أكسجين فائقة لمنع الأكسدة والنتانة.

3.2 العمر الافتراضي المطلوب

يجب أن تحافظ العبوة على جودة المنتج طوال مدة الصلاحية المقصودة, والتي يمكن أن تتراوح من أيام إلى سنوات حسب نوع الطعام. تعتبر الأفلام ذات الخصائص العازلة العالية ضرورية لمتطلبات العمر الافتراضي الممتد.

3.3 شروط التخزين والتوزيع

درجة حرارة, رطوبة, التعرض للضوء, والضغوط الجسدية المحتملة أثناء النقل وعرض البيع بالتجزئة يمكن أن تؤثر على اختيار الفيلم. تتطلب الظروف القاسية حلول تغليف أكثر قوة.

3.4 التدقيق المطلوب

يجب أن تتوافق أفلام تغليف المواد الغذائية مع لوائح سلامة الأغذية ومعايير الهجرة ذات الصلة في الأسواق المقصودة. يتم تقييم عوامل مثل التركيب الكيميائي وخطر انتقال المواد إلى الغذاء.

رابعا. أفلام الخياطة لمختلف الأطعمة

4.1 الأطعمة الجافة

وجبات خفيفة, الحبوب, البضائع المخبوزة, إلخ. تتطلب في المقام الأول حواجز رطوبة ممتازة لمنع التكتل, توقف أو فقدان الهشاشة. توفر المواد مثل البولي بروبيلين حماية جيدة للرطوبة.

4.2 المنتجات الطازجة

تستفيد الفواكه والخضروات من الأغشية الدقيقة المثقبة أو عالية نفاذية الغاز التي تسهل عملية التنفس وتعديل الجو لتأخير النضج والشيخوخة.

4.3 اللحوم والمأكولات البحرية

الأطعمة الغنية بالبروتين عرضة للأكسدة والتلف البكتيري. حواجز أكسجين ممتازة مثل كحول الإيثيلين فينيل (إيفوه) تعتبر البوليمرات المشتركة مع المواد المانعة للتسرب الفعالة ضرورية.

4.4 منتجات الألبان

منتجات الألبان مثل الحليب, جبن, الزبادي الخ. تتطلب أفلامًا عازلة للرطوبة العالية والتي تكون أيضًا حواجز للرائحة/النكهة لتجنب النكهات أو امتصاص الرائحة. نقاء المواد أمر حيوي.

4.5 السلع المخبوزة

بالإضافة إلى الحماية من الرطوبة, تتطلب المنتجات المخبوزة حواجز رائحة ممتازة لمنع تساقط النكهة أو نقل الروائح غير المرغوب فيها من مواد التعبئة والتغليف.

V. اتجاهات التعبئة والتغليف الناشئة

5.1 حلول مستدامة وصديقة للبيئة

مع تزايد الوعي البيئي, حيوي, قابل للتحلل, قابلة لإعادة التدوير, ويتزايد تفضيل خيارات التغليف المتجددة ذات البصمة الكربونية المنخفضة.

5.2 التعبئة والتغليف النشطة والذكية

أفلام متقدمة تتضمن إضافات لتنظيم الرطوبة, خصائص مضادة للميكروبات, كسح الإيثيلين الخ. جنبا إلى جنب مع أجهزة الاستشعار المتكاملة لمراقبة الجودة والسلامة يجري تطويرها.

5.3 تسميات نظيفة والشفافية

مدفوعة باتجاهات التسمية النظيفة, يفضل المستهلكون الحد الأدنى من المعالجة وعدد أقل من الإضافات الاصطناعية بينما يطالبون بالشفافية بشأن مواد التعبئة والتغليف وسلامتها.

سادسا. استنتاج

6.1 أهمية الاختيار الأمثل لأفلام تغليف المواد الغذائية

يعد اختيار فيلم التغليف الأنسب أمرًا بالغ الأهمية لضمان جودة الطعام, تمديد مدة الصلاحية, تقليل النفايات, والحفاظ على سلامة المنتج من المعالجة إلى الاستهلاك.

6.2 نهج شامل للحماية

تتطلب استراتيجية التعبئة والتغليف الفعالة دراسة شاملة للخصائص الفريدة للمنتج, العمر الافتراضي المقصود, ظروف التخزين, المشهد التنظيمي, فضلا عن أهداف الاستدامة والتقدم التكنولوجي الناشئ. مع الأفلام المناسبة, يمكن لمصنعي المواد الغذائية تحسين الحماية, تقليل الخسائر, وتلبية توقعات المستهلكين المتطورة فيما يتعلق بالنضارة وسلامة الأغذية.

6.3 شركة Shantou Kaixuan Packaging Co., المحدودة. – شريكك الموثوق

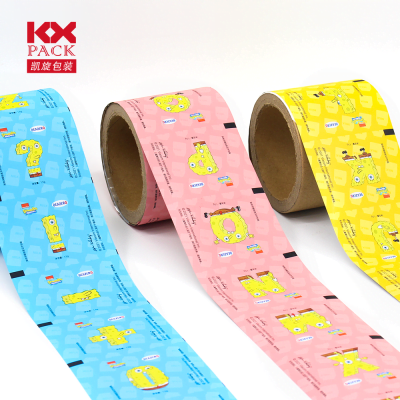

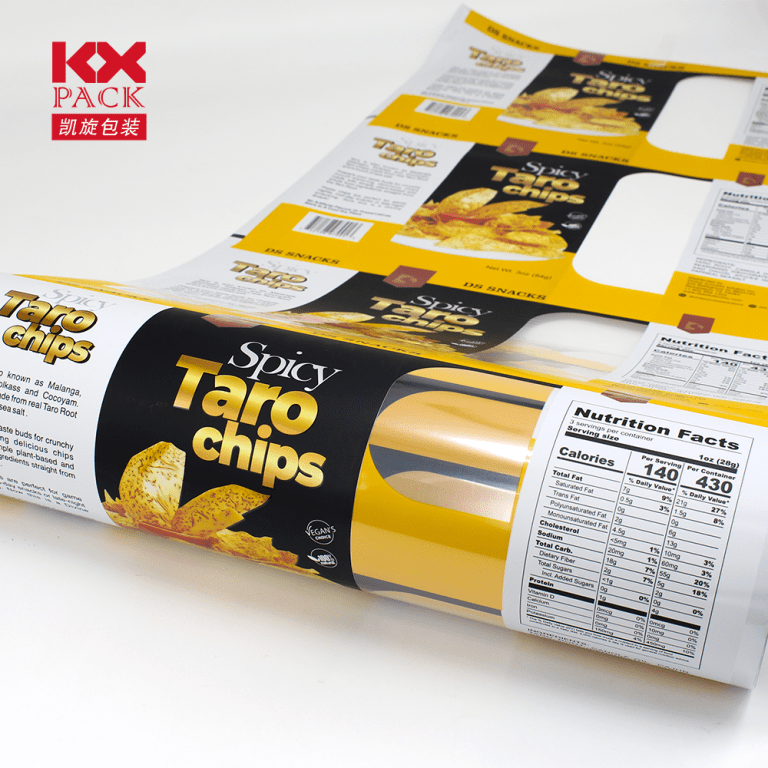

شركة Shantou Kaixuan Packaging Co., المحدودة. هي شركة مصنعة مباشرة تركز على حلول التعبئة والتغليف لأكثر من ذلك 20 سنوات, مع الخبرة في الطباعة الملونة, تقرحات, وصنع الحقائب. كمزود متكامل للتصميم, إنتاج, والمبيعات, تقدم Kaixuan حلول التعبئة والتغليف الشاملة.

بمنشأة بمساحة 200.000 متر مربع تضم أ 100,000 ورشة عمل خالية من الغبار, تتميز Kaixuan بقدرات متقدمة بما في ذلك آلات الطباعة بالحفر عالية السرعة ذات 12 لونًا بسرعة 300 متر في الدقيقة, آلات نفطة أوتوماتيكية عالية السرعة بتكنولوجيا ألمانية, آلات صنع الأكياس ذات الختم الثماني الجوانب, وغيرها من المعدات عالية المستوى.

الشراكة مع Kaixuan تضمن الوصول إلى المنتجات المبتكرة, أفلام تغليف عالية الجودة مصممة خصيصًا لتلبية احتياجاتك الخاصة من المنتجات الغذائية, مدعومة بعقدين من الخبرة الصناعية وقدرات التصنيع المتطورة.