Saamgestelde film-voedselverpakking Nog 'n sprong

Saamgestelde film-voedselverpakking Nog 'n sprong

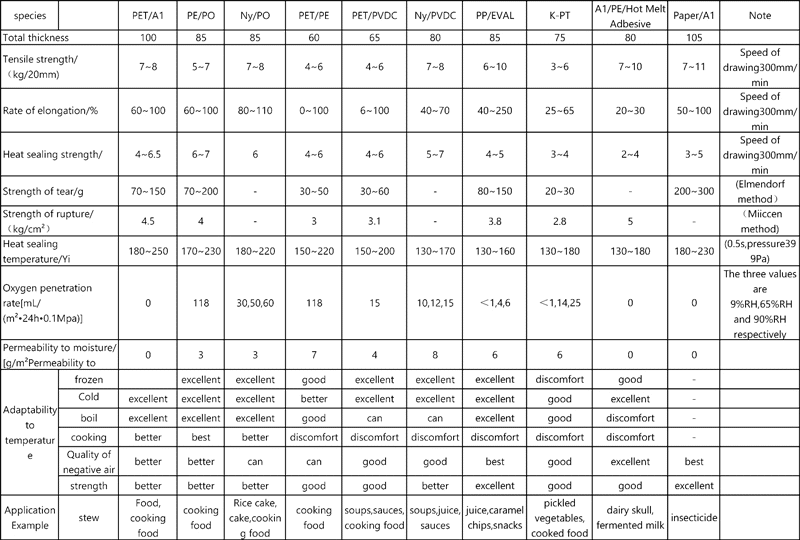

There are many kinds of packaging materials, but there are great differences in performance.

Although it has many excellent properties, kan in 'n sekere reeks gebruik word, maar 'n enkele materiaal kan nie al die eienskappe van verpakkingsmateriaal hê nie, kan nie aan die algehele vereistes van voedselverpakking voldoen nie.

Daarom, according to the different purpose of use, the different packaging materials are combined to make it have a variety of comprehensive packaging performance, composite packaging materials are thus produced.

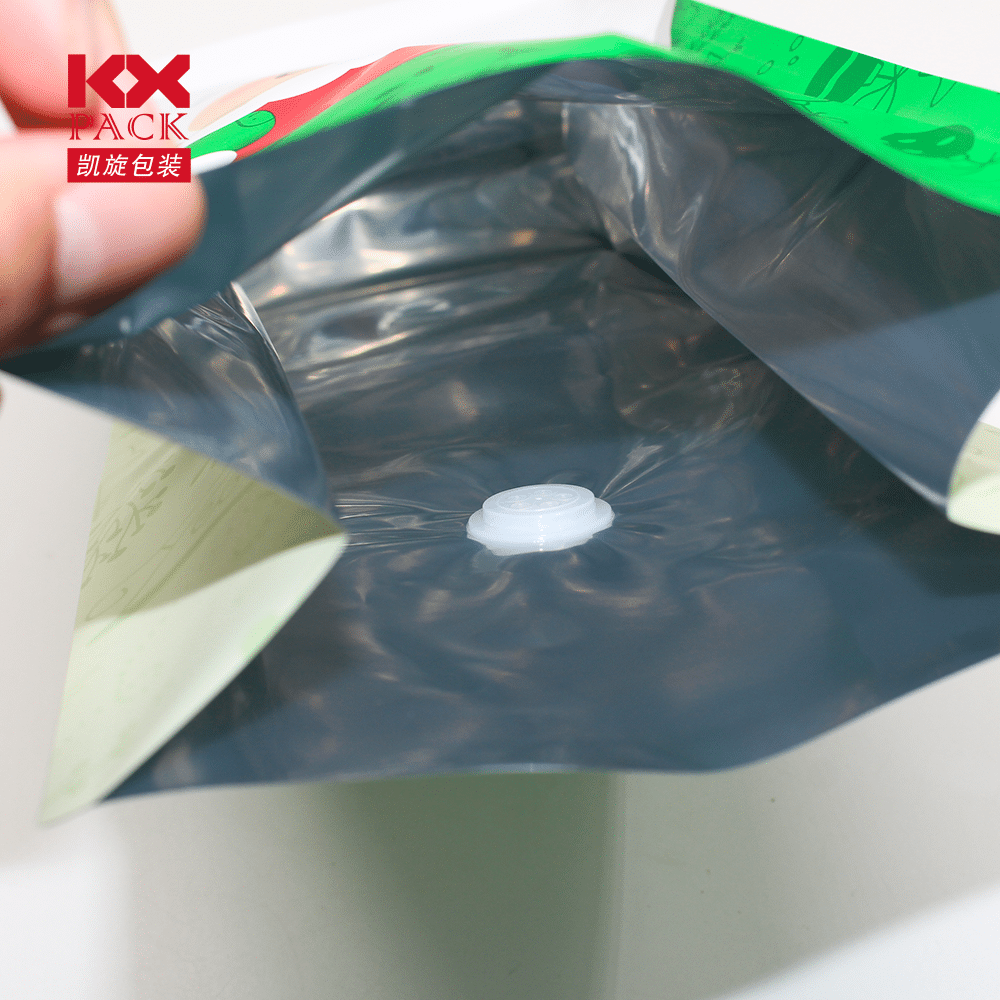

Composite film packaging material refers to two or more layers of different kinds of flexible materials, through a certain combination of technology.

“Structured” multilayer materials. The composite substrates are plastic film, aluminum foil and paper.

Composite packaging film, has become the most important category of food packaging materials, is the development direction of food packaging.

Composite film has two advantages incomparable to single film:

- Good comprehensive packaging performance.

Composite film, which combines all the single film properties that make up composite materials,

With high barrier, hoë sterkte, good heat sealing, high resistance

Temperature and packing operation adaptability.

- Good health and safety performance.

The printing layer can be placed in the middle, with non-polluting contents and protection

Protect the role of printing decorative layer.

The structural requirements of composite film for food inner packaging:

- Inner layer requirements: nie-toksies, smaakloos, oil resistance, chemiese weerstand

Goed, with heat sealing or adhesion. Commonly used inner layer has PE,

CPP, Eva, ionic polymer and other thermoplastics. - Outer requirements: good optical properties, good printability, wear and heat resistance, with strength and rigidity. The commonly used outer layer is PA, PET, BOPP, PC, aluminum foil and paper.

- Intermediate layer requirements: with high barrier (Yang xiang, anti

Damp and shade), among which aluminum foil and PVDC are the most commonly used products

Kind of.

The representation of composite film:

From left to right are the outer layer, middle layer and inner layer materials,

Byvoorbeeld: paper /PE/AL/PE, outer layer provides printing performance, medium

The intermediate PE layer acts as a bond, and the intermediate AL provides barrier and stiffness

Degree, inner PE provides heat sealing performance.

Hoe om goeie herwinning aan te pasE composite film with us?

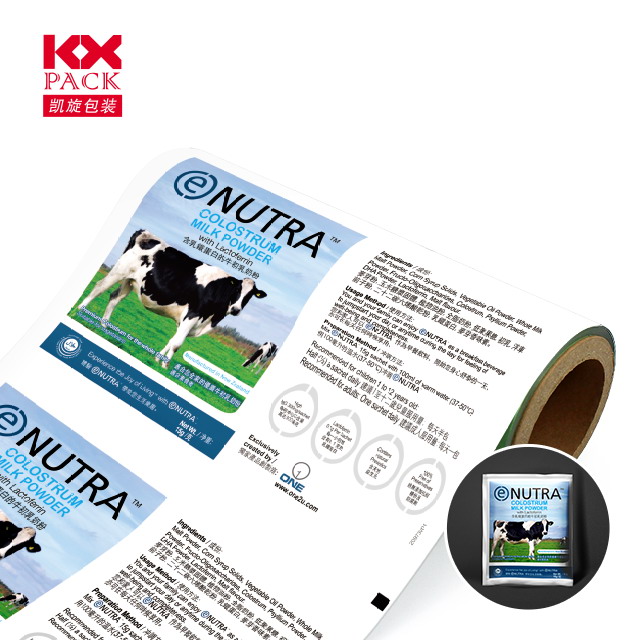

Shantou Kaixuan Packaging Co., Ltd

Direkte fabrieksfokus op verpakking oor 20 jare,veral in kleurdrukwerk,blister en sak maak. Geïntegreer in ontwerp,produksie en sale.Kaixuan fabriek beslaan 'n oppervlakte van 20000㎡,toegerus met 'n 10000 vlak stofvrye werkswinkel,300m/min 12 kleur hoë-spoed diepdruk masjien,outomatiese hoëspoed blistermasjien met Duitse tegnologie,agtkant-seëlsakmaakmasjien en ander hoëstandaard-sakmaaktoerusting.

Geen Benseen Geen Ketoon Ink.Intussen, ons gebruik benseenvry en ketoonvry,ink en ander eko-vriendelike materiale. Die daaglikse kapasiteit kan bereik 150 ton,voldoen absoluut aan u behoeftes in Safe,Doeltreffend en gesond.

Ons aanvaar pasgemaakte bestellings. Om u 'n korrekte kwotasie te bied,ons moet u besonderhede benodig soos hieronder:

- Aantal

- Druk kleur ontwerp

- Materiale en dikte

- Grootte

Vir meer gedetailleerde tipes of vrae oor voedselverpakkingsfilms, verwys asseblief na: https://kxpack.com/product-category/plastic-film/

Ons verskaf maar is nie beperk tot produkte van hoë gehalte nie, mededingende pryse, uitstekende diens, ens.